The Real Timeline of Custom Manufacturing: A Procurement Guide for Singapore Enterprises

Expert Quick Answer

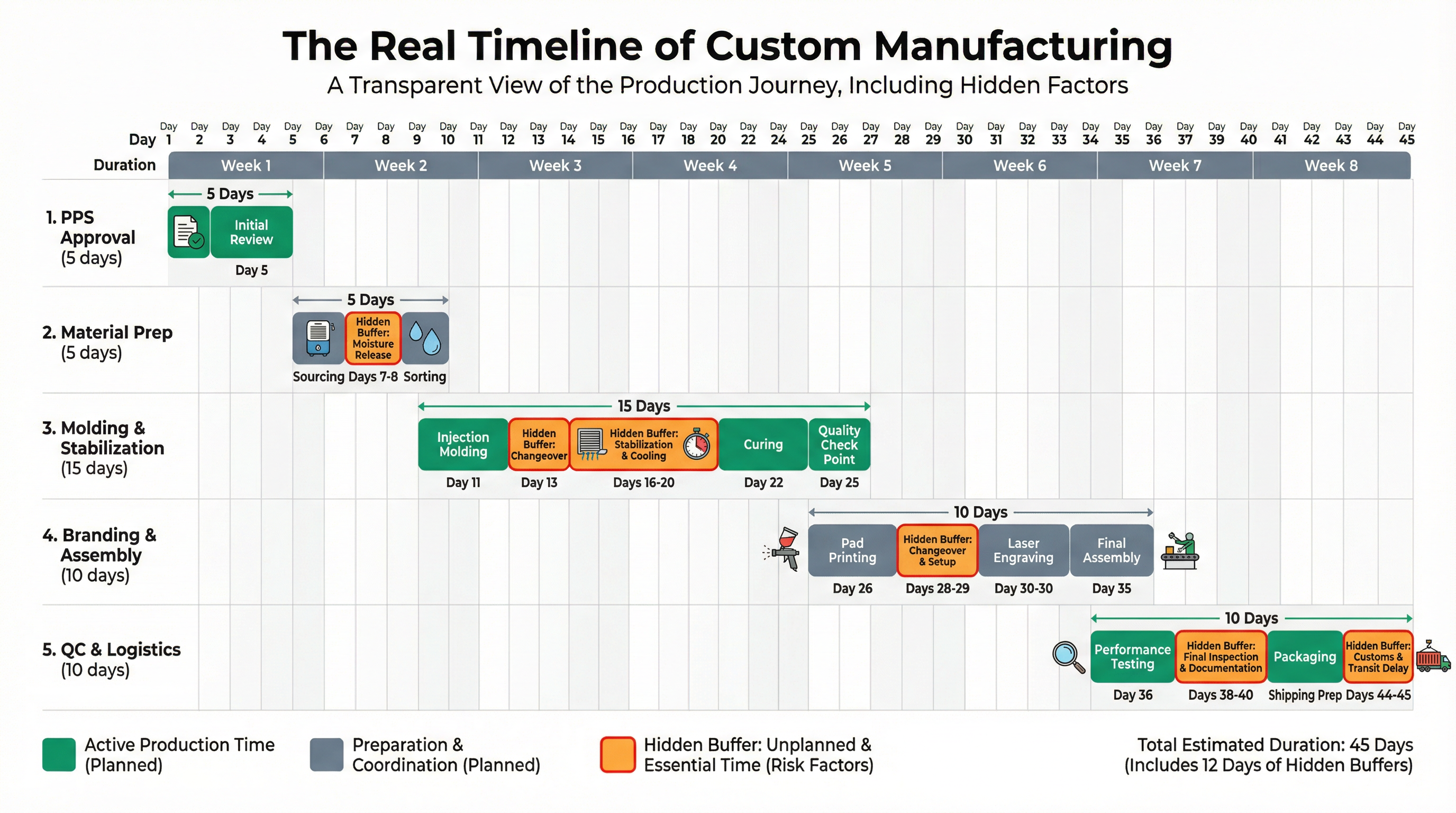

For custom eco-friendly corporate gifts in Singapore, the realistic lead time is 35 to 45 days, not the "2 weeks" often promised by local stockists. This timeline includes three critical but often ignored phases: Material Stabilization (48 hours for bio-composites), Multi-SKU Changeovers (1-2 days for color splits), and Compliance Testing. Skipping these steps to meet a rushed deadline creates a high risk of mold growth, logo peeling, or customs rejection.

Why "Lead Time" Is the Most Dangerous Variable in Procurement

In my 15 years advising Fortune 500 procurement teams in Singapore, I have seen more projects fail due to unrealistic timelines than budget constraints. When a supplier quotes "14 days," they are usually referring to production time—the time the machine is running. They are conveniently omitting the time required for material curing, quality control, and the inevitable friction of logistics.

For Singaporean enterprises, this miscalculation has three severe consequences:

- Brand Reputation Risk: Rushed production often skips the post-molding stabilization phase, leading to products that warp or develop mold after distribution.

- Budget Overruns: "Urgent" air freight to fix a delayed sea shipment can triple your logistics costs overnight.

- Compliance Failure: There is zero buffer for independent lab testing, which is mandatory for food-contact items in the EU and increasingly scrutinized in Singapore.

The 5-Step Custom Manufacturing Process (And Where It Goes Wrong)

To control your timeline, you must understand the physical reality of the factory floor. Here is the actual breakdown of a "simple" order.

1. The "Clock Start" Gap (Days 1-5)

The lead time clock does not start when you sign the PO. It starts when the Pre-Production Sample (PPS) is approved. In practice, we see a 5-day gap where finance processes the deposit while the factory waits. Pro Tip: Issue a "Letter of Intent" to reserve raw materials while payment clears.

2. Material Preparation & Mixing (Days 6-10)

For eco-friendly materials like wheat straw or bamboo fiber, we cannot just pour pellets into a hopper. The raw biomass must be dried for 4-8 hours to remove moisture. Skipping this leads to steam bubbles and structural weakness.

3. Injection Molding & Stabilization (Days 11-25)

This is the core production phase. However, if you have ordered multiple colors, you must factor in changeover downtime. Every color switch requires purging the machine, which can halt production for 4 hours. Furthermore, bio-composites require a 48-hour "cooling phase" to release internal moisture before they can be packed.

4. Branding & Assembly (Days 26-35)

Your logo is not applied during molding; it is a secondary process. If you choose a complex 3-color logo, you are likely using Pad Printing, which requires ink curing time between colors. As detailed in our analysis of branding bottlenecks, a "simple" logo can add 10 days to your timeline compared to In-Mold Labeling.

5. Quality Control & Logistics (Days 36-45)

Third-party inspection takes 1 day, but booking the inspector takes 3 days. Then, the goods must be trucked to the port. In Singapore, we also face the unique "Monsoon Factor"—heavy rains can delay container loading at regional ports.

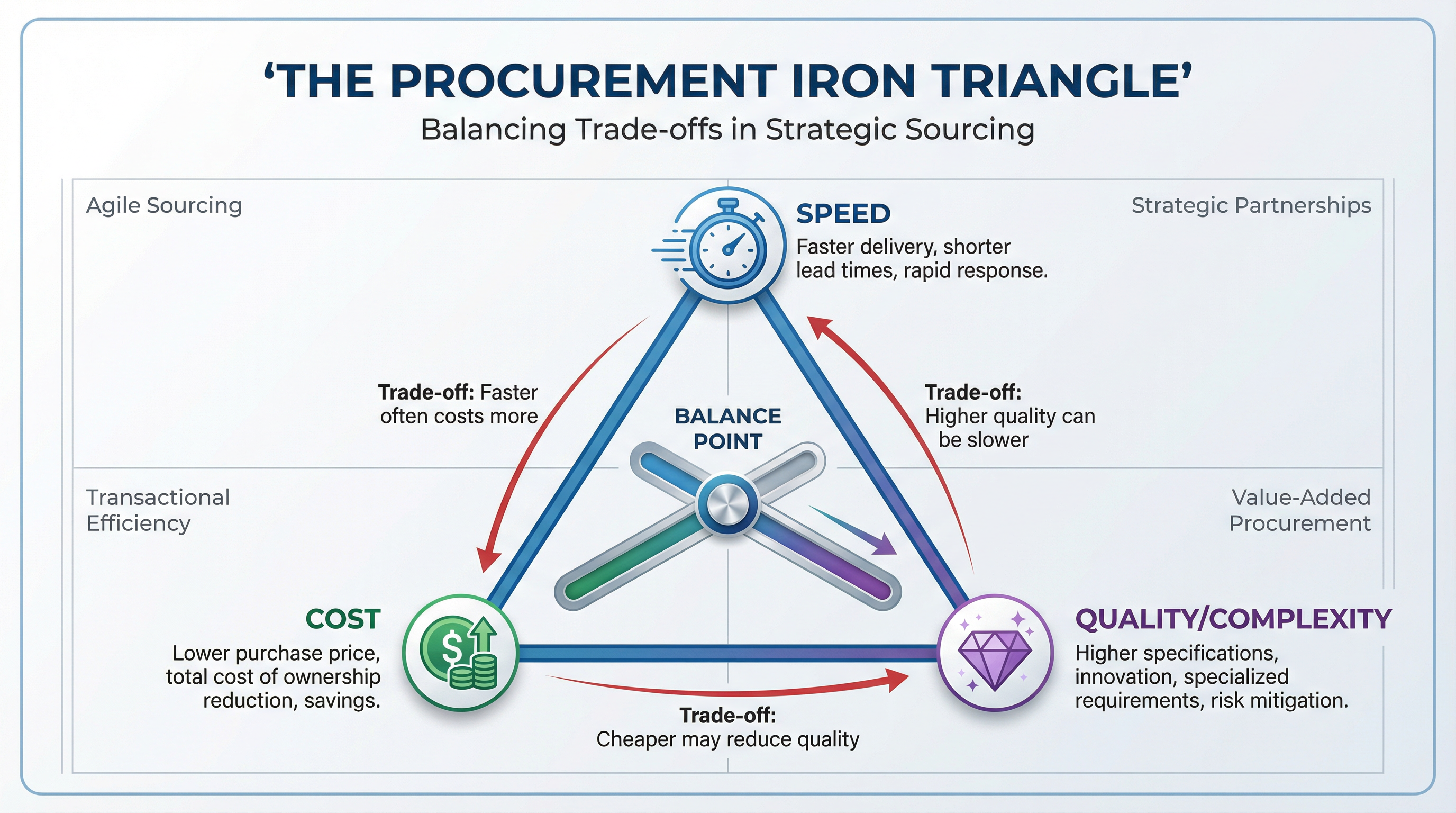

Critical Decision Factors: The "Iron Triangle" of Procurement

You cannot have it all. In custom manufacturing, you must trade off between Speed, Complexity, and Cost.

If Speed is Priority #1:

- Choose Single-SKU (one color, one size).

- Use Laser Engraving instead of printing (no ink drying time).

- Accept Air Freight costs.

If Brand Consistency is Priority #1:

- Allow +10 days for Pantone Matching.

- Require Pre-Production Samples (adds 7 days).

- Stick to Sea Freight to protect budget.

Strategy by Enterprise Scale

For SMEs & Startups

Focus on Agility. You likely lack the volume to demand a dedicated production line. Your strategy should be "Off-the-Shelf + Custom Branding." Buy existing stock (blank goods) and brand them locally in Singapore. This reduces lead time to 14 days but limits you to standard colors.

For MNCs & Regional HQs

Focus on Compliance. Your risk is not just late delivery; it is a lawsuit. Ensure your timeline includes 5 days for independent lab testing (SGS/Intertek) to verify that your "eco-friendly" gift is free of melamine and heavy metals. Centralize procurement to hit MOQs that justify a custom production run (usually 3,000+ units).

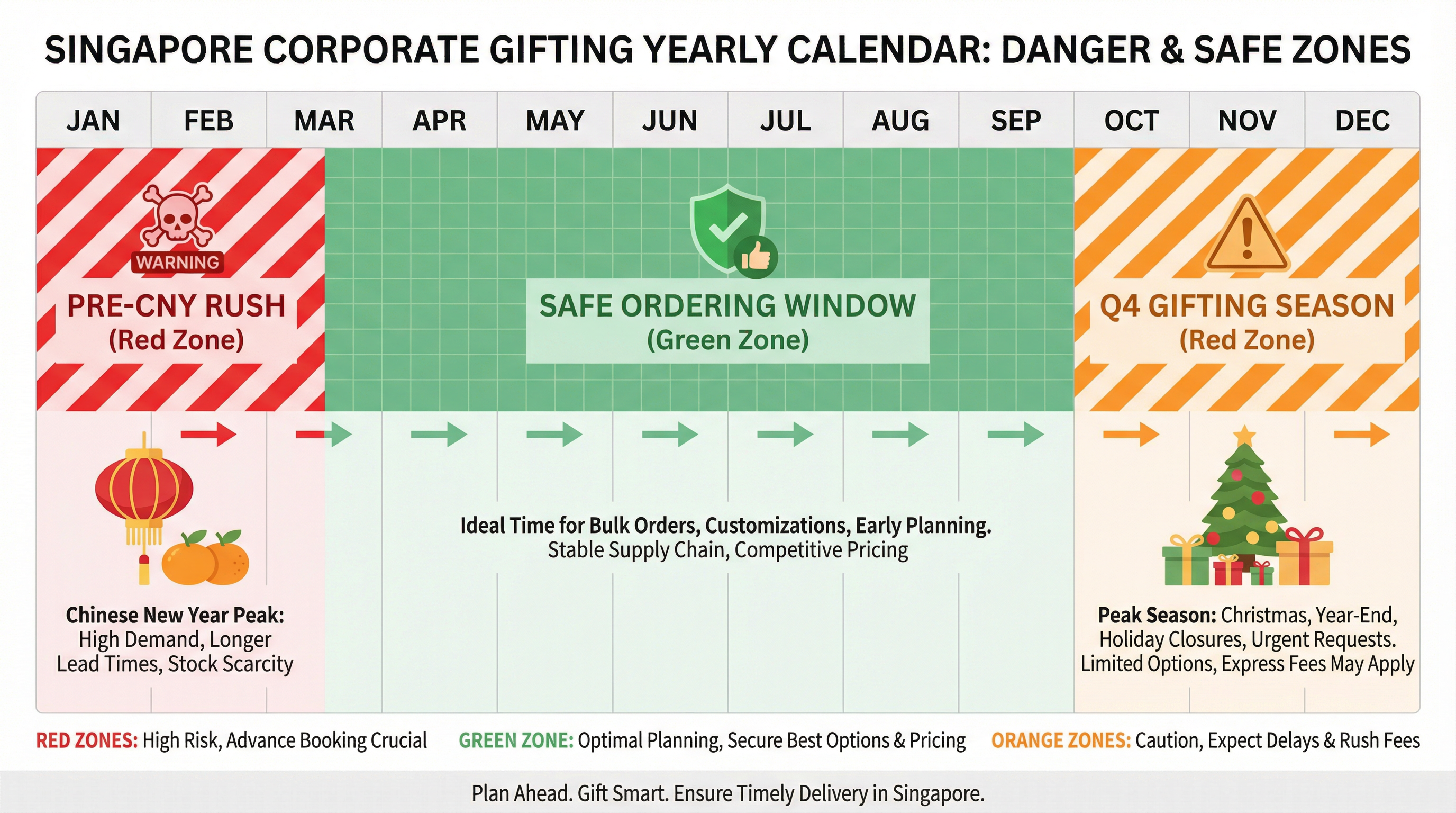

Singapore Market Specifics: The "Red Zone" Dates

In Singapore, the calendar is your enemy. There are two "Red Zones" where production capacity vanishes:

- Pre-CNY (Chinese New Year): Factories in the region shut down for 3-4 weeks. Orders must be placed by November 15th to guarantee delivery before CNY.

- Q4 Corporate Gifting Rush: From October to December, lead times naturally extend by 15-20% due to congestion. If you want gifts for a December D&D, order in September.

Frequently Asked Questions

Can I expedite a custom mold order?

Rarely. You can expedite shipping (Air vs. Sea), but expediting molding or curing risks product failure. Physics cannot be bribed.

Why is the lead time for eco-friendly products longer?

Bio-materials require lower processing speeds to prevent burning and a mandatory 48-hour post-molding stabilization period to release moisture.

Does a "Rush Fee" guarantee delivery?

No. It usually just prioritizes your order in the queue. It does not make the machine run faster or the paint dry quicker.

Stop Gambling with Your Event Timeline

Don't let a "2-week promise" turn into a 6-week nightmare. Let us help you build a realistic, risk-proof procurement strategy that delivers quality on time, every time.

Consult Our Supply Chain Experts