The Branding Bottleneck: Why 'Simple' Logos Add 10 Days to Your Lead Time

When reviewing a production schedule for branded eco-friendly tableware, the "Logo Printing" line item often looks deceptively simple—typically allocated 2 to 3 days. In reality, the choice between Pad Printing and In-Mold Labeling (IML) is a critical decision variable that can silently inject a 10-day delay into your critical path, often discovered only after the purchase order is signed.

For procurement teams sourcing sustainable corporate gifts like bamboo fiber lunch boxes or wheat straw tumblers, the assumption is often that branding is a post-production afterthought. You make the product, then you stamp the logo. However, with bio-composite materials, the chemistry of the substrate fundamentally changes how ink adheres, turning a simple stamping process into a complex curing timeline.

The Pad Printing Trap: It's Not Just Stamping

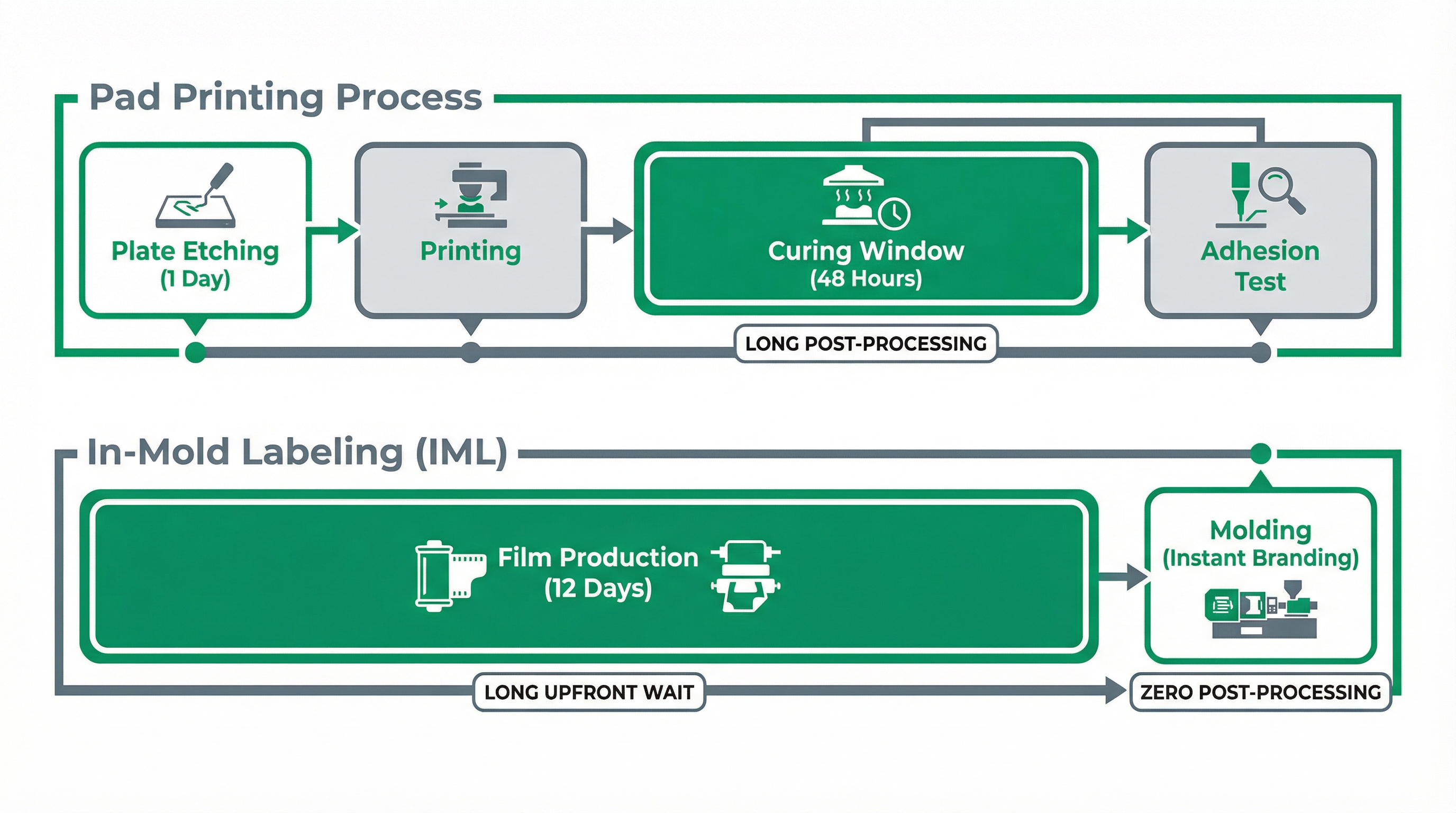

Pad printing is the industry standard for low Minimum Order Quantities (MOQs) because it is flexible and cheap. A silicone pad picks up ink and transfers it to the 3D surface of your bottle or container. On standard ABS plastic, this ink dries almost instantly.

However, when applied to eco-friendly materials like bamboo fiber or rPET, the surface energy is different. These materials are often porous or have uneven textures. To ensure the logo doesn't scratch off with a fingernail, factories must use specialized two-component inks that require a hardener. This introduces a mandatory "curing window"—a period of 24 to 48 hours where the product must sit untouched in a temperature-controlled room before it can be packed. If you rush this phase to meet a tight production lead time, the logo will fail the adhesion tape test upon arrival, leading to a full batch rejection.

In-Mold Labeling: Speed at the Cost of Agility

In-Mold Labeling (IML) offers a seductive alternative: the logo is fused into the product during the molding process itself. There is no post-production printing step, no drying time, and no risk of scratching. The product comes out of the mold fully branded.

The hidden cost here is not financial, but temporal. IML requires the production of a specific film label that must be printed, cut, and loaded into the injection mold robot. This label production is a separate supply chain with its own 12-15 day lead time. Unlike pad printing plates which can be etched in an afternoon, IML films must be prepared weeks in advance. If your artwork is not finalized 3 weeks before production starts, IML is mathematically impossible without delaying the entire order.

The "Simple" Logo Misconception

A common friction point arises when a brand team requests a "simple 1-color logo" but specifies a Pantone color that requires a double-hit print to achieve opacity on a dark eco-material. For example, printing bright white text on a dark green bamboo fiber container often requires two layers of white ink to prevent the background color from bleeding through.

Each layer needs to flash-dry before the next is applied. This effectively doubles the printing time per unit. On an order of 5,000 units, a "simple" logo change can add 3 full days of machine time, plus the extended final curing period.

Strategic Recommendations for Procurement

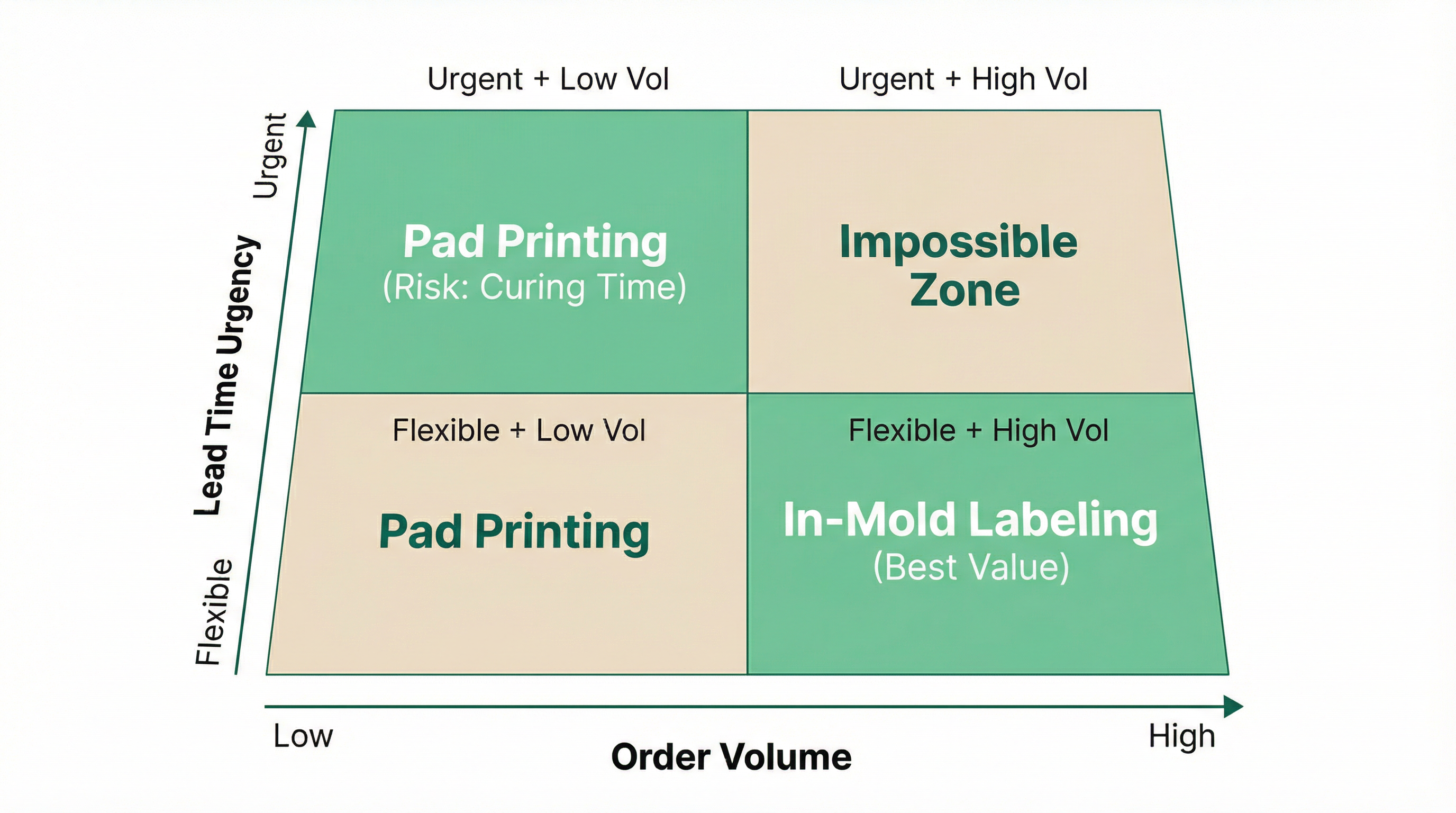

To mitigate these risks, we advise clients to lock in artwork files at the same time as the Purchase Order, not after. For urgent orders under 30 days, Pad Printing is the only viable option, but it requires an acceptance of the curing window. For recurring orders where durability is paramount, investing in the upfront setup time for IML pays off by removing the printing bottleneck from future production runs entirely.

Understanding these physical and chemical constraints allows you to build a buffer into your project timeline that reflects reality, rather than an optimistic best-case scenario that rarely exists in sustainable manufacturing.