The Hidden 'Cooling Phase': Why Bio-Composites Need 48 Hours Before Packing

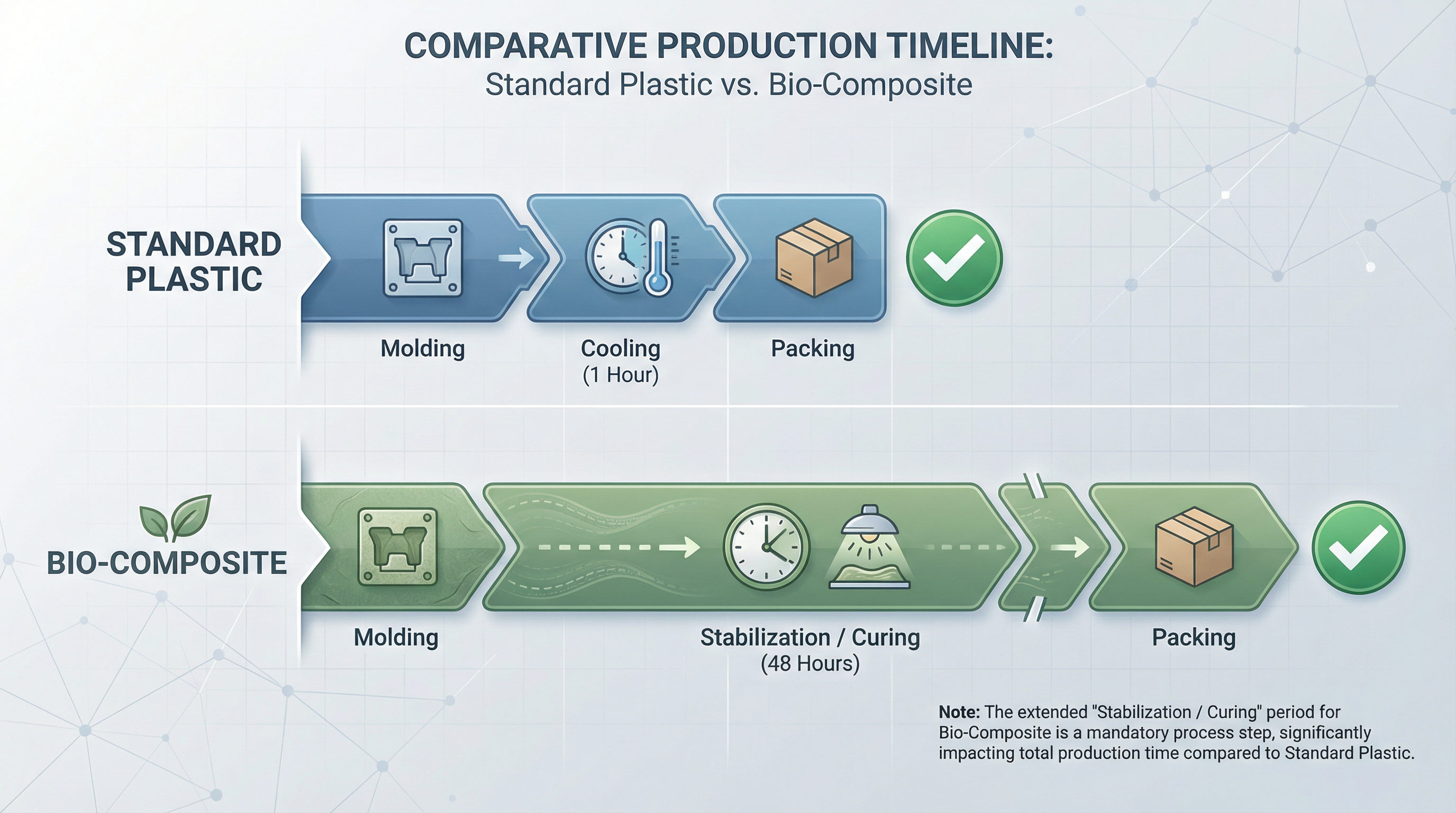

In the rush to meet a tight event deadline, the most dangerous instruction a procurement manager can give a factory is: "Pack it as soon as it comes off the line." For standard polypropylene, this is efficient. For bio-composites like wheat straw or bamboo fiber, it is a recipe for a mold disaster that will only reveal itself weeks later, when your client opens the box.

As a compliance consultant specializing in sustainable materials, I frequently investigate "quality failures" that are actually "patience failures." The root cause is often a misunderstanding of how bio-based materials behave immediately after injection molding. Unlike inert plastics, these materials are "alive" with moisture dynamics that require a mandatory, non-negotiable stabilization period.

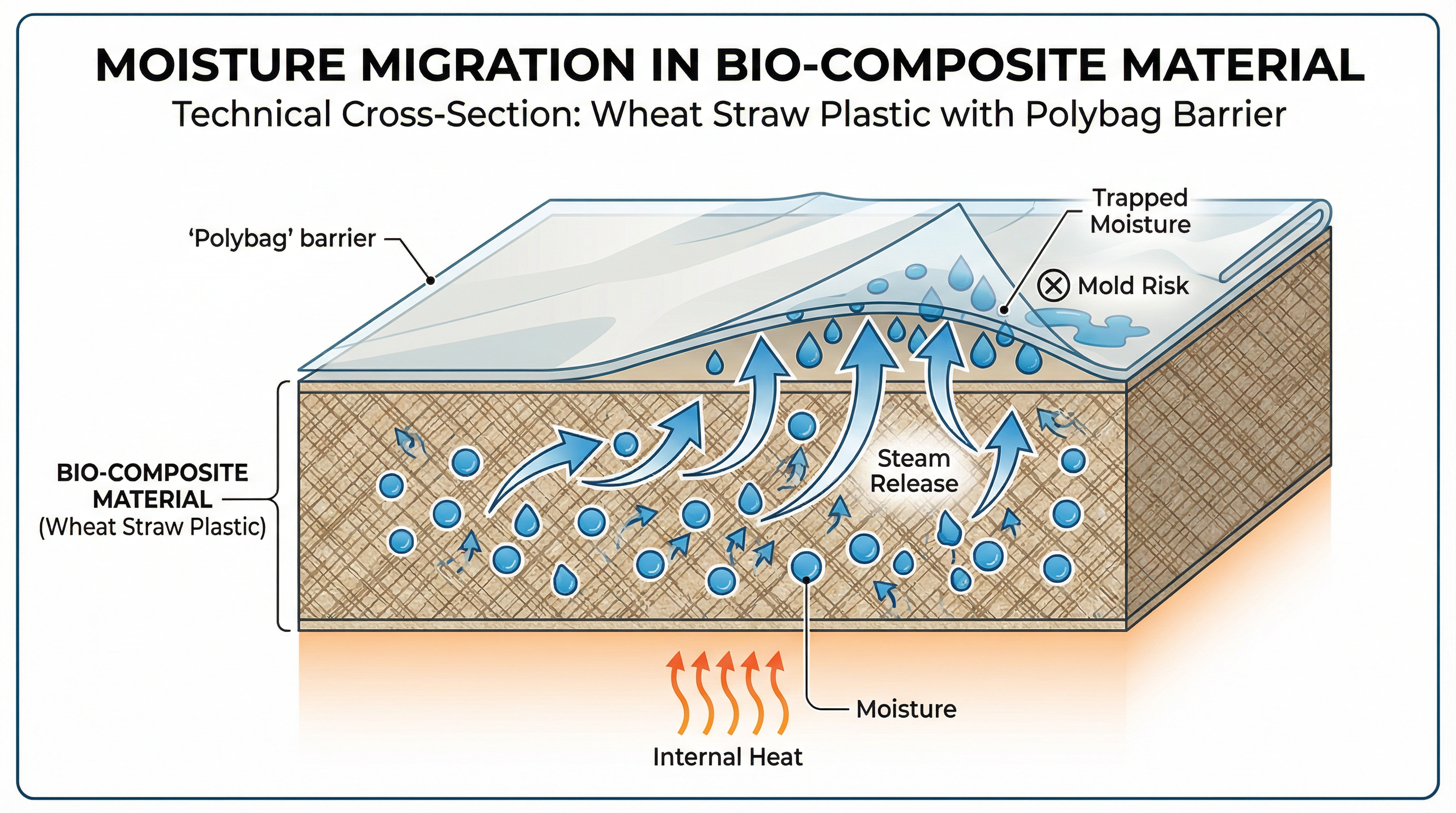

The "Steam Trap" Phenomenon

Bio-composites contain natural fibers—cellulose, lignin, and hemicellulose—that are hygroscopic (water-absorbing). During the high-heat injection molding process (160°C - 180°C), any residual moisture deep within these fibers turns into high-pressure steam.

When the part is ejected from the mold, it is solid to the touch but internally unstable. Over the next 48 hours, this internal steam migrates to the surface as it cools and re-equilibrates with the ambient environment. If you seal this product in a polybag immediately after molding, you trap this escaping moisture against the surface of the product.

In a warm, dark shipping container, this trapped micro-climate creates the perfect incubator for mold growth. I have seen entire containers of "perfectly manufactured" bamboo lunch boxes arrive covered in white fuzz simply because they were packed 6 hours too early.

The Dimensional Stability Factor

Beyond mold risk, immediate packing compromises the structural integrity of the product. Bio-composites have a different shrinkage rate than pure plastic. They continue to settle and warp slightly as they cool.

A "cooling fixture" or jig is often required to hold the shape of a lid or container while it stabilizes. If a hot lid is snapped onto a hot base and packed, the differential cooling rates can cause the lid to warp permanently, leading to leakage issues. This "settling time" is a critical, invisible component of the production lead time that cannot be expedited.

The Compliance Implication

From a regulatory standpoint, products that develop mold during transit fail safety standards for food-contact materials. Even if the mold is wiped off, the spores remain, and the product is considered contaminated. This leads to total recalls and liability issues that far outweigh the benefit of saving 2 days in production.

Strategic Advice for Procurement

When planning your timeline, explicitly ask your supplier: "What is your post-molding stabilization protocol?" A competent factory will tell you they need a "buffer zone" in their warehouse where parts sit on open racks for 24 to 48 hours before final assembly.

Do not view this as "dead time." View it as a "quality curing" phase. If a supplier promises to "rush production" by skipping this step, they are not doing you a favor—they are handing you a ticking time bomb. Accept the 2-day stabilization period as a necessary insurance policy for the integrity of your sustainable goods.