The Multi-SKU Trap: Why 5 Colors Take Twice as Long as 1

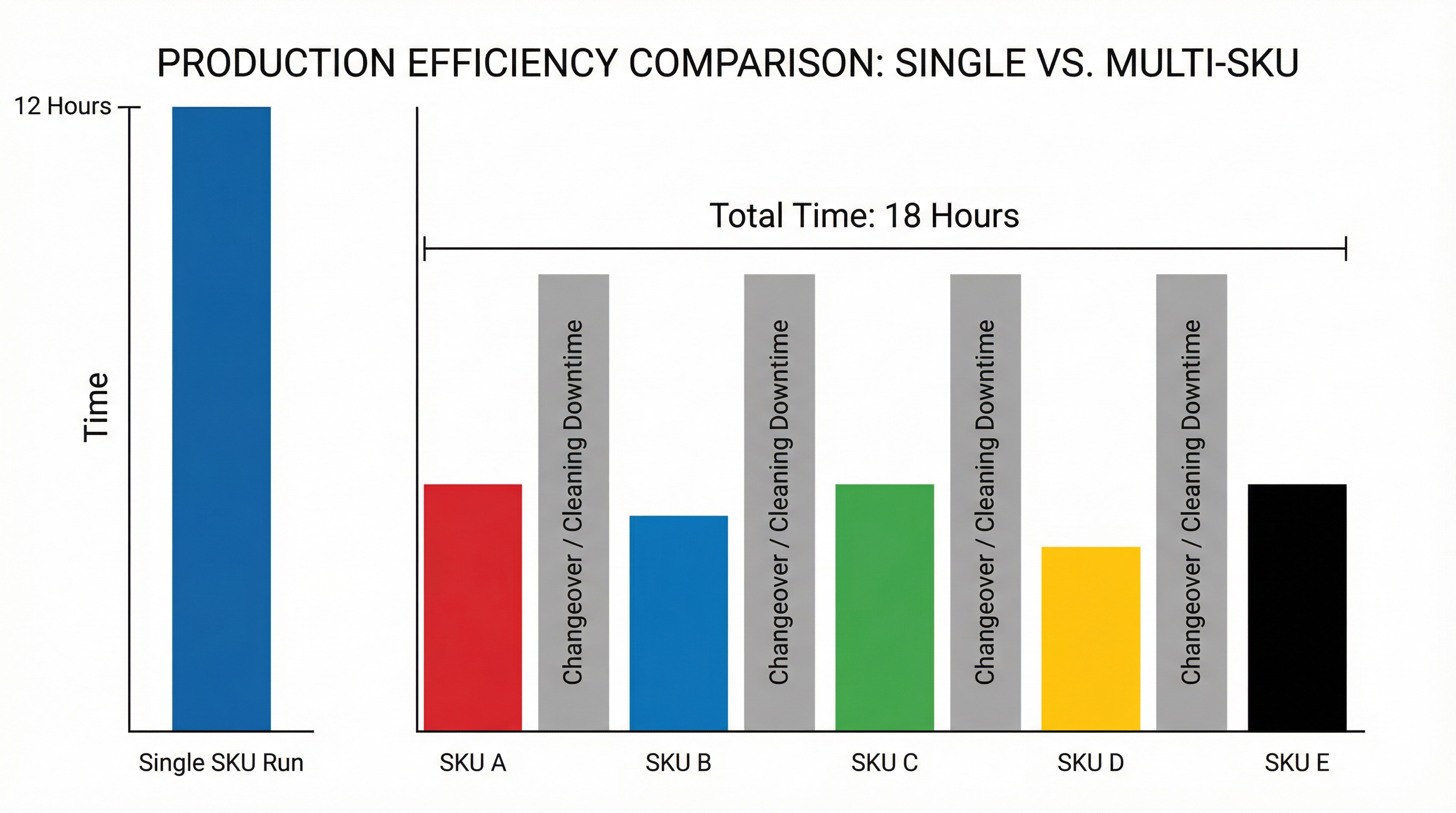

From a marketing perspective, offering a corporate gift in five different Pantone colors is a brilliant strategy to maximize employee engagement. From a factory floor perspective, however, splitting a 5,000-unit order into five 1,000-unit batches is a mathematical disaster that can silently double your production lead time.

As a project manager overseeing injection molding lines for eco-friendly materials, I often see procurement teams treat "Total Quantity" as the only variable that matters for timeline estimation. They assume that producing 5,000 wheat straw tumblers takes the same amount of machine time regardless of color distribution. This assumption ignores the physical reality of "changeover downtime"—the invisible thief of production capacity.

The Physics of Color Changeovers

When you switch from a dark forest green to a natural beige in an injection molding machine, you cannot simply swap the hopper. The entire barrel and screw assembly must be purged of the previous resin. For standard plastics, this might take 30 minutes. But for bio-composites like bamboo fiber or coffee grounds, the material is heat-sensitive and prone to carbonizing if left stagnant.

This means a color change requires a full machine strip-down and manual cleaning to prevent black specks from contaminating the lighter color. This process takes 3 to 4 hours per switch. If your order has 5 colors, that is 15 to 20 hours of pure downtime—effectively two full shifts where the machine produces nothing. This downtime is not factored into standard lead time estimates, which are based on continuous run rates.

The Kitting Bottleneck

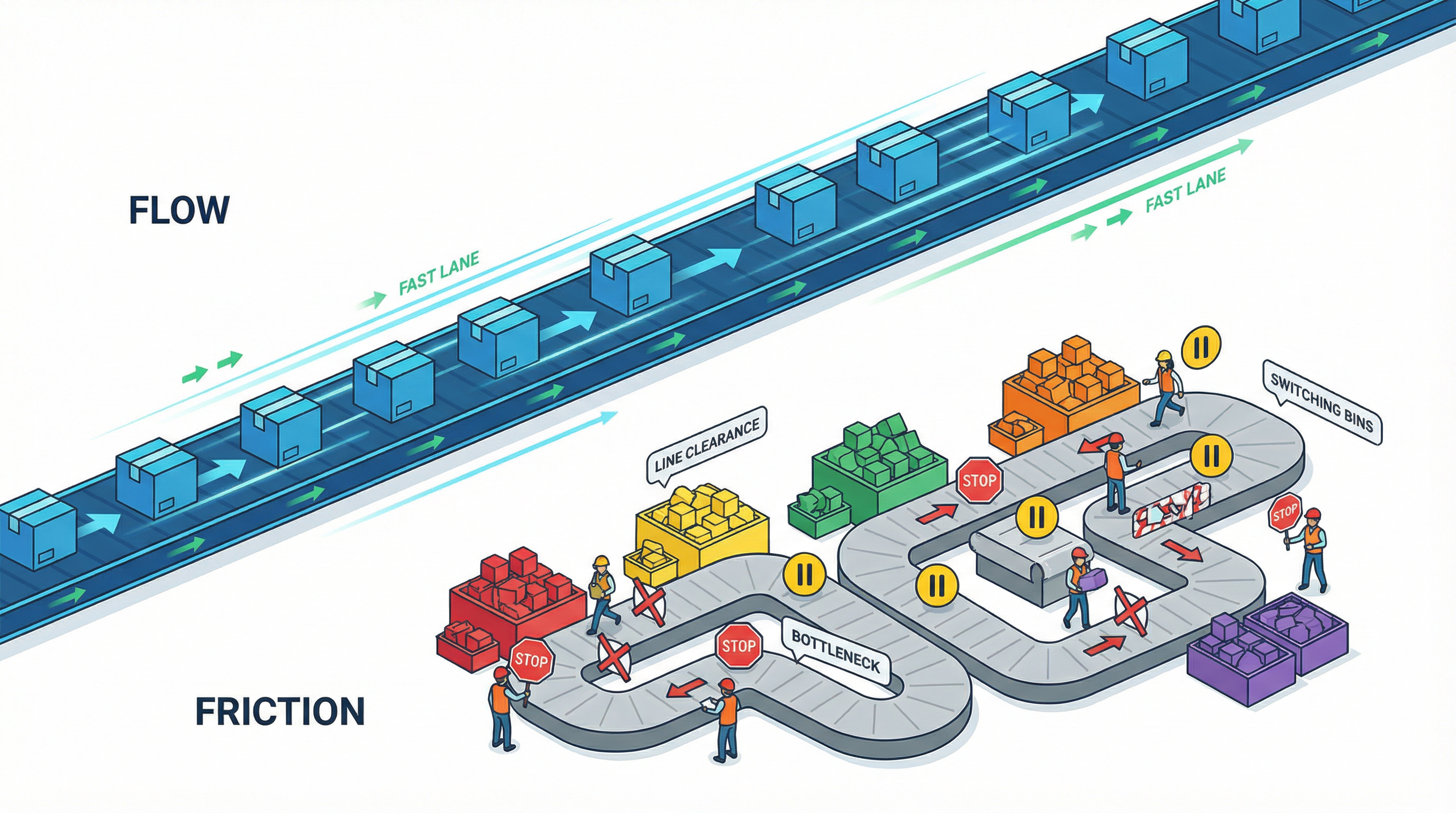

The complexity compounds at the assembly and packing stage. A single-SKU order allows for a "flow line" setup: workers perform one repetitive motion, achieving maximum speed. A multi-SKU order forces a "batch and queue" setup.

If you ordered 1,000 units each of Blue, Green, Red, Yellow, and Black, we cannot pack them simultaneously unless we have five separate packing lines (which we don't). We must pack all Blue units, stop, clear the line of Blue packaging materials, bring in Green packaging materials, and restart. This "line clearance" is mandatory to prevent a Blue tumbler from ending up in a box labeled "Green"—a critical quality failure.

The "Leftover" Material Problem

Furthermore, raw material is not bought in exact unit quantities; it is bought in 25kg bags. To produce exactly 1,000 units of a specific color, we might need 180kg of material. We have to mix 200kg (8 bags). The remaining 20kg is often wasted because it cannot be stored long-term once mixed with the color masterbatch.

This material inefficiency forces factories to charge higher unit prices for split-color orders, or worse, wait until they can combine your "Red" run with another client's "Red" run to save material—a practice that introduces unpredictable delays.

Strategic Advice for Project Managers

If your deadline is tight, simplify your SKU count. A single color run of 5,000 units will always exit the factory 3-5 days faster than a 5-color split. If variety is non-negotiable, acknowledge the "complexity tax" in your timeline planning. Add 1 day of buffer for every additional SKU beyond the first. This realistic approach prevents the panic of last-minute delays when the production line is inevitably halted for its fourth cleaning of the week.