When a client requests laser engraving on a standard ABS plastic pen, the setup is almost instantaneous. We load the "ABS Standard" profile, set the focal length, and hit run. The result is a crisp, high-contrast mark that looks exactly like the digital proof.

However, when that same client switches to a wheat straw or bamboo fiber composite to meet their sustainability goals, they often assume the customization process remains equally straightforward. In practice, this is often where customization decisions start to be misjudged.

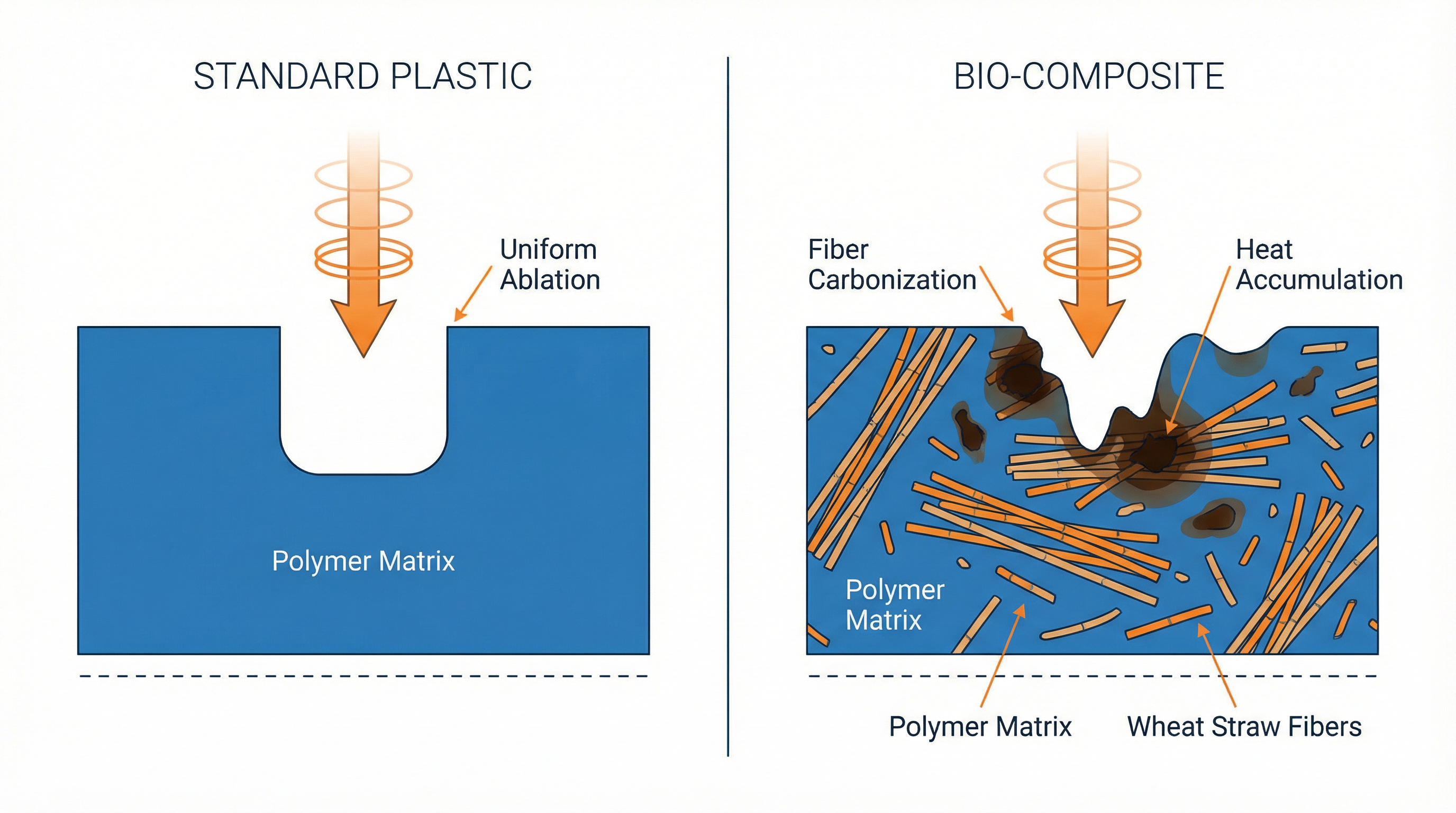

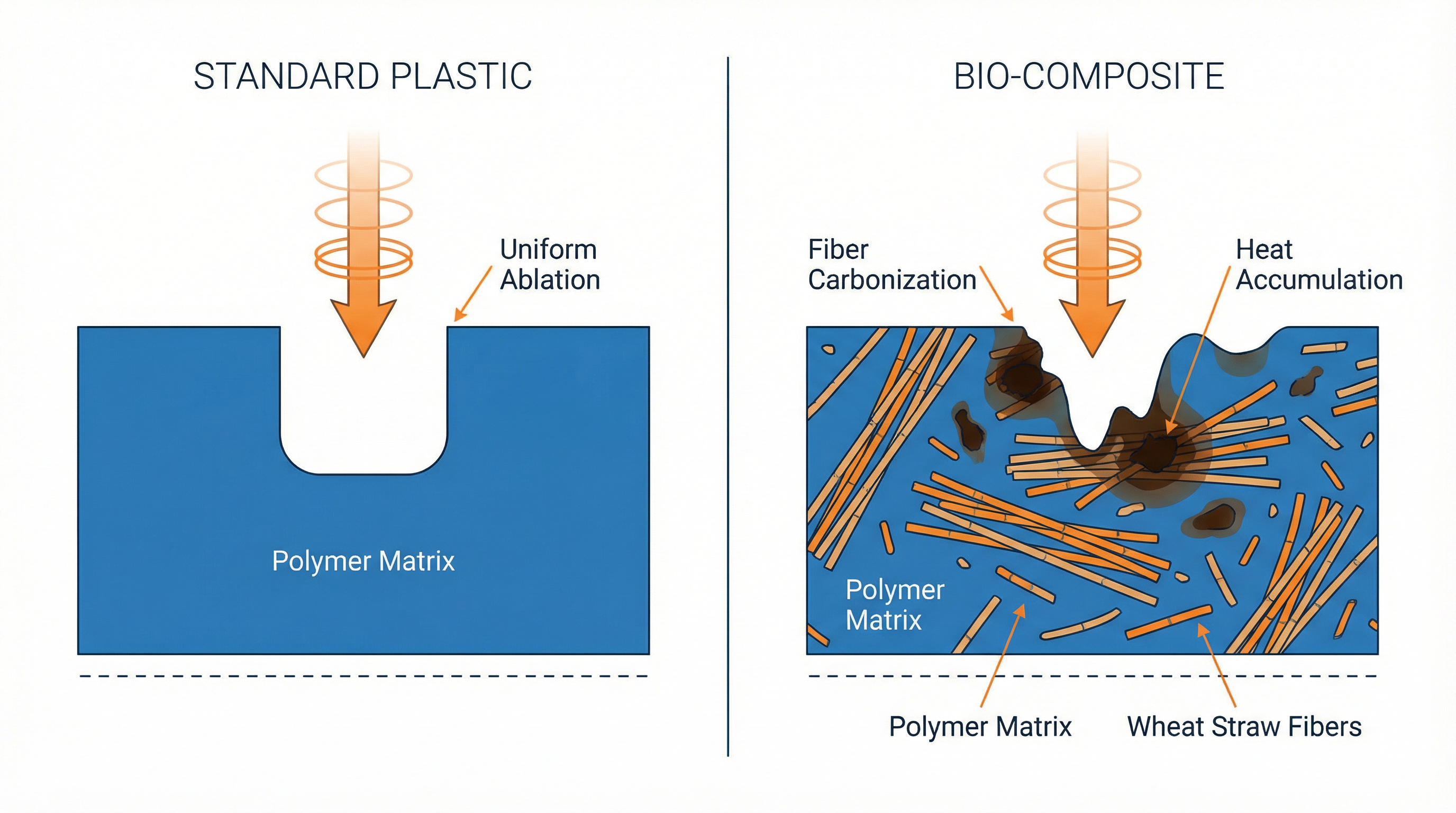

Bio-composites are not uniform blocks of polymer; they are organic mixtures containing starch, lignin, and cellulose fibers suspended in a plastic matrix. When a high-energy laser beam hits this heterogeneous surface, it doesn't just "ablate" material—it cooks it.

The "Burnt Sugar" Phenomenon

Standard plastics melt or vaporize cleanly under laser heat. Wheat straw composites, however, contain significant amounts of natural sugars and starches. When exposed to the intense, localized heat of a laser marker (often exceeding 300°C at the focal point), these organic components undergo caramelization and carbonization.

Instead of a clean, engraved groove, an uncalibrated laser can produce a sticky, dark brown residue—essentially burnt sugar. This "charring" effect not only looks unprofessional but can also smear if touched immediately after processing.

Why "Plug-and-Play" Fails with Bio-Materials

Unlike homogeneous plastics, bio-composites have inconsistent thermal conductivity. A laser setting that works perfectly on one spot might burn too deep on a cluster of wheat fibers just millimeters away, or fail to mark a patch of pure PP binder. This inconsistency demands a much narrower operating window for laser power and speed.

The Hidden Calibration Phase

To achieve a clean, consistent mark on bio-composites, we cannot rely on standard libraries. For every new batch of material (which can vary in fiber content by ±5%), our engineering team must perform a "grid test."

We run a matrix of 20-30 test squares, varying power from 10% to 40% and speed from 500mm/s to 2000mm/s. We are looking for the "Goldilocks Zone": enough energy to discolor the surface for visibility, but not enough to trigger the carbonization chain reaction that leads to charring.

This calibration process adds approximately 24-48 hours to the initial setup time for any new eco-friendly product order. It is a critical quality control step that ensures your logo looks intentional and premium, rather than like a scorch mark.

Design Implications for Procurement

Understanding these thermal dynamics allows for smarter design choices. Because bio-composites struggle with fine detail under heat, we recommend:

- Avoiding heavy solid fills: Large engraved areas accumulate heat, increasing the risk of warping and charring. Outline styles often yield cleaner results.

- Accepting lower contrast: The most durable mark on wheat straw is often a subtle "tone-on-tone" texture rather than a high-contrast black burn.

- Minimum line weight: Extremely fine lines may be interrupted by surface fibers. We recommend a minimum stroke width of 0.2mm for legibility.

By anticipating these physical constraints, procurement teams can adjust their artwork expectations early, preventing the need for multiple rounds of failed sampling and keeping the project timeline on track.

Related Articles

The Pantone Illusion: Why Bio-Materials Defy Standard Color Matching

Why your wheat straw product doesn't match your Pantone chip. A factory project manager explains the physics of substrate interference in eco-friendly manufacturing.

The Hidden 'Cooling Phase': Why Bio-Composites Need 48 Hours Before Packing

A compliance consultant's warning on why rushing the packing process for wheat straw and bamboo fiber products leads to mold disasters. We explain the science of moisture migration and the mandatory stabilization period.

Worried About Logo Quality on Eco-Materials?

Our engineering team performs material-specific laser calibration for every order. Let us help you get the perfect mark.

Consult Our Experts