There is a counter-intuitive reality in sustainable manufacturing: the more "natural" fiber you add to a plastic composite, the harder it becomes to print on. For procurement teams, this often manifests as a confusing quality failure—samples that look perfect on arrival but fail the "Scotch tape test" three months later.

When transitioning from standard ABS or pure Polypropylene (PP) to bio-composites like wheat straw or bamboo fiber, most quality control protocols focus heavily on the material's structural integrity or biodegradability. However, the most immediate commercial risk lies in a property that is invisible to the naked eye: surface energy.

In my role auditing factory compliance for European markets, I frequently encounter batches of eco-friendly promotional products where the branding rubs off with minimal friction. This isn't usually a result of "cheap ink" or "bad machines." It is a fundamental misunderstanding of how bio-fillers alter the surface chemistry of the substrate, specifically regarding dyne levels and the necessity of surface pretreatment.

The Surface Energy Deficit

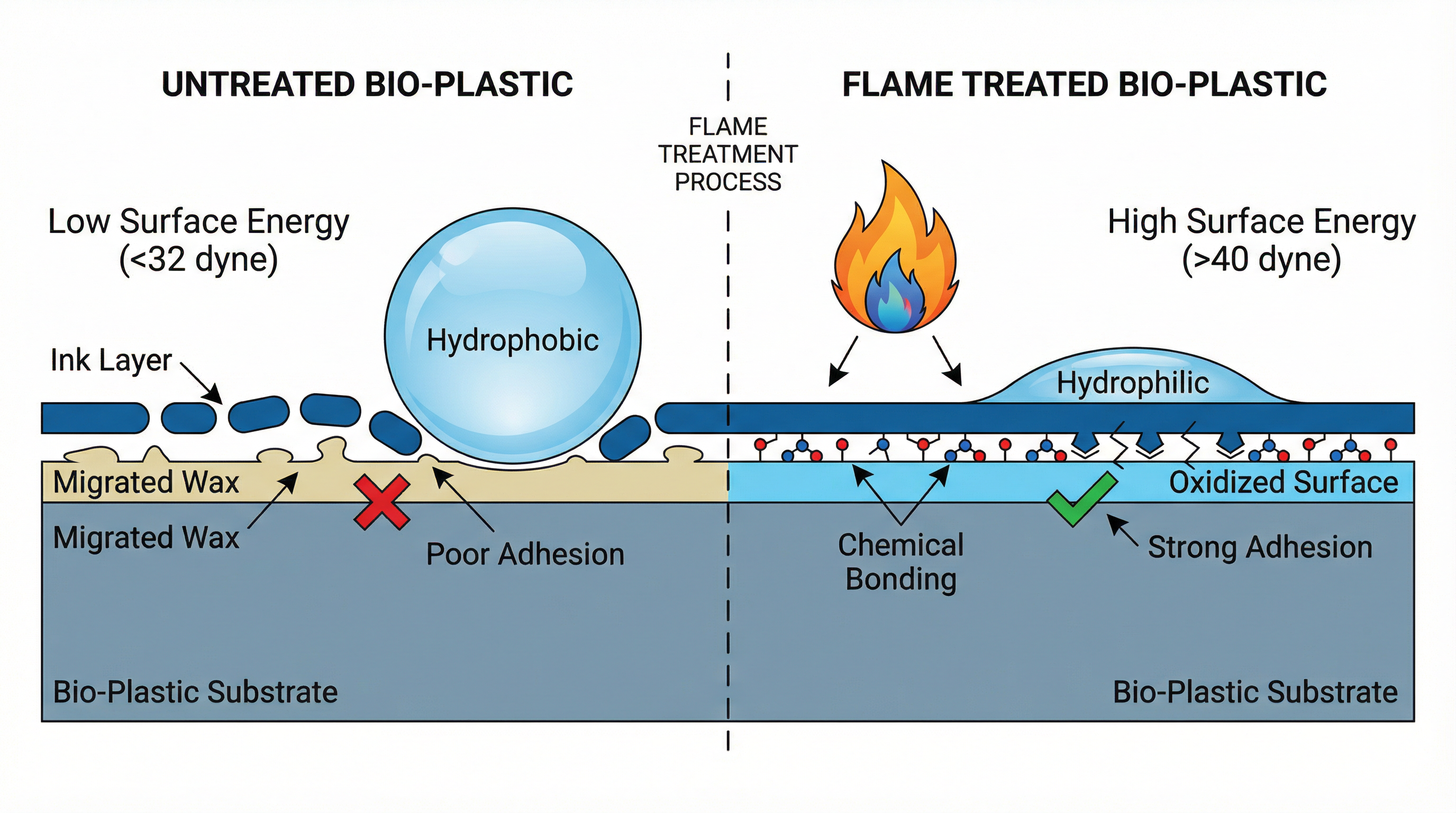

To understand the failure, we must look at the physics of adhesion. For ink to bond permanently to a plastic surface, the surface energy of the substrate (measured in dynes/cm) must be significantly higher than the surface tension of the liquid ink. Standard Polypropylene (PP), the base for most wheat straw composites, is naturally "low energy" (around 29-31 dynes/cm). It is chemically inert and hydrophobic, meaning it naturally repels liquids.

When you introduce organic fillers like wheat straw or coffee grounds, you might expect the surface to become rougher and more receptive. In practice, the opposite often occurs during injection molding. The polymer matrix tends to form a "skin" over the natural fibers, and the processing additives (lubricants and mold release agents) migrate to the surface. These additives can drive the surface energy down even further, creating a "non-stick" layer that no standard pad printing ink can penetrate.

The "False Positive" Risk

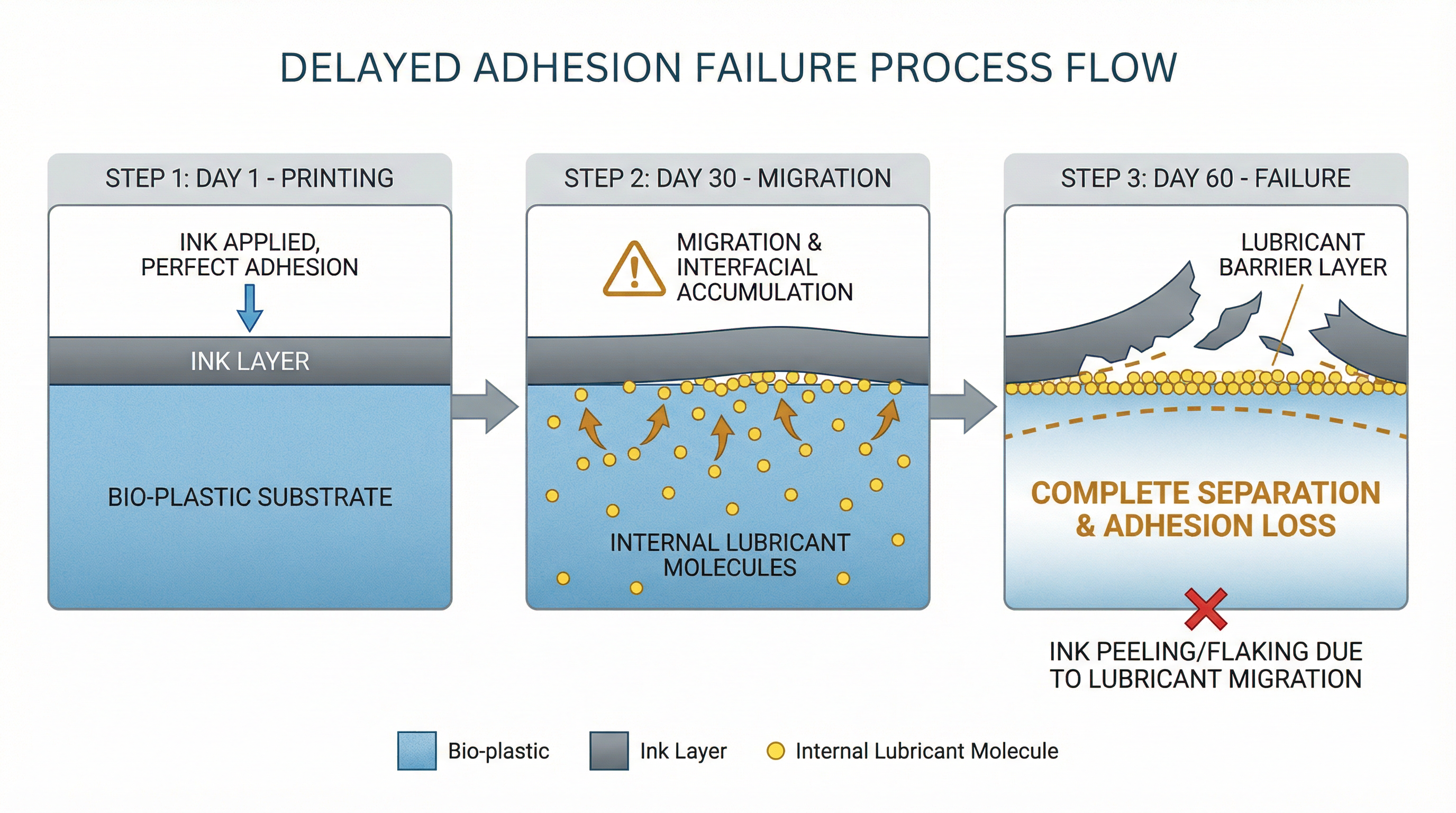

Freshly printed ink on untreated bio-plastic often relies on a weak mechanical bond. It may pass a scratch test 24 hours after production. However, as the plastic cures and internal waxes continue to migrate to the surface over 30-60 days, they can physically push the ink layer off, leading to delayed adhesion failure after the goods have been distributed.

Why "Flame Treatment" is Non-Negotiable

For standard plastics, a quick wipe with alcohol or a primer might suffice. For bio-composites, this is rarely enough. The industry standard solution—which many low-cost quotations omit to save time—is Flame Treatment or Corona Discharge.

This process involves passing the product through a precise gas flame or high-voltage arc for a fraction of a second just before printing. This isn't about heating the part; it's about oxidizing the surface molecules. This oxidation breaks the inert molecular chains and adds polar functional groups (like hydroxyls and carbonyls) to the surface. These new groups act as chemical "anchors" that the ink can grab onto.

In practice, this is often where customization process decisions start to be misjudged. A factory might quote a standard 7-day lead time, assuming standard pad printing. However, properly executing flame treatment requires:

The Process Cost

It adds an entire manual or semi-automated step to the production line. Every single pen or box must be oriented and treated individually immediately before printing.

The Validation Cost

It requires "Dyne Pen" testing throughout the shift to ensure the treatment level remains above 38-40 dynes. If the flame intensity drifts, the entire batch fails.

The Procurement Decision Matrix

When evaluating suppliers for eco-friendly merchandise, the question should not just be "Can you print this logo?" but "What is your pretreatment protocol for this material?"

If a supplier claims they use a "special ink" that requires no pretreatment on PP-based bio-plastics, proceed with extreme caution. While some hardener-added inks exist, they often have shorter pot lives and can be brittle. The physical modification of the surface energy via flame or corona remains the gold standard for durability.

Figure 2: The Mechanism of Delayed Failure. Internal lubricants migrate to the surface over time, displacing ink that wasn't chemically bonded.

The trade-off is clear: accepting the additional 1-2 days of lead time and the marginal cost increase for proper surface treatment is the only way to ensure your brand's logo doesn't flake off before the product's lifecycle ends. In the context of sustainable products, durability is a core component of eco-friendliness—a product that looks worn out in a week is likely to be discarded, negating the environmental benefit of the material itself.

Related Articles

The 'Golden Sample' Fallacy: Why Single-Unit Sign-Offs Fail for Eco-Materials

Why relying on a single 'perfect' pre-production sample for bamboo or wheat straw products is a statistical trap, and how to implement a 'Limit Sample' protocol instead.

The Hidden 'Cooling Phase': Why Bio-Composites Need 48 Hours Before Packing

A compliance consultant's warning on why rushing the packing process for wheat straw and bamboo fiber products leads to mold disasters. We explain the science of moisture migration and the mandatory stabilization period.

Worried About Logo Quality on Eco-Materials?

Our engineering team performs material-specific laser calibration for every order. Let us help you get the perfect mark.

Consult Our Experts