"The bamboo bodies are ready. The laser engraving is done. Why can't you ship?"

I hear this frustration often. The client sees photos of their beautiful bamboo lunch boxes stacked in our warehouse, finished and branded. They assume the order is 99% complete.

But I have to tell them the truth: "We are waiting for the silicone sealing rings."

This is the **Sub-Component Trap**. In modern manufacturing, no single factory makes everything under one roof. We are experts in bamboo and woodworking. We do not mold silicone. We do not weave polyester straps. We do not cast stainless steel buckles. We buy them.

And that means your lead time is not determined by *our* speed. It is determined by the speed of our slowest sub-supplier.

### The Tier 2 Blind Spot

When you approve a 30-day production timeline, you are usually looking at the "Tier 1" schedule—the time it takes for us to cut, shape, and finish the main bamboo product.

What is often invisible is the **Tier 2 Supply Chain**.

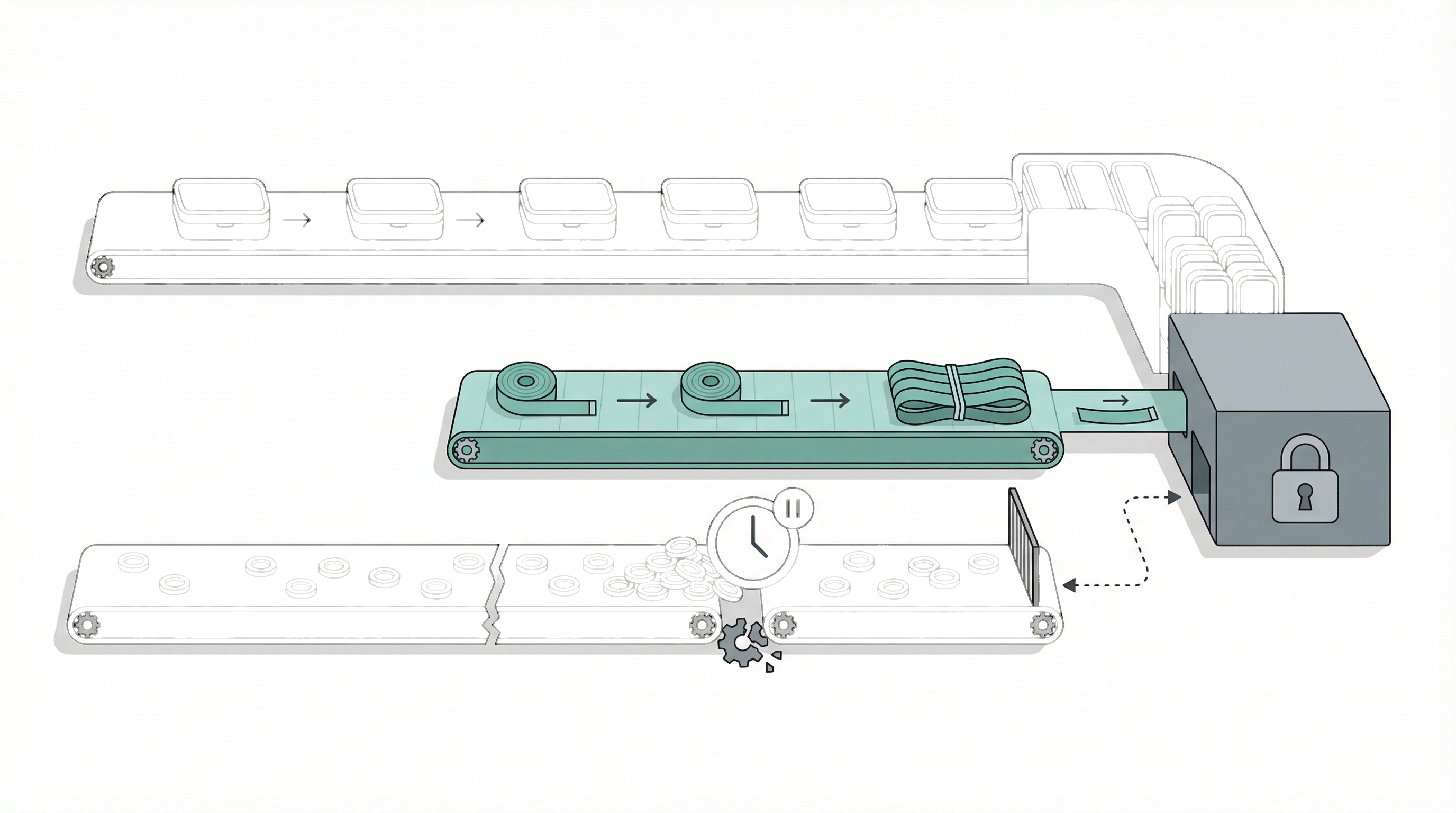

Let's look at a standard "Eco-Friendly Bento Box" gift set. It seems simple, but it relies on three synchronized timelines:

1. **Bamboo Lid & Base (Tier 1 - Us):** 20 days.

2. **Elastic Nylon Strap (Tier 2 - Outsourced):** 15 days.

3. **Food-Grade Silicone Seal (Tier 2 - Outsourced):** 25 days.

If the silicone factory has a machine breakdown, or if they prioritize a larger order from a medical device company, their 25 days becomes 35 days.

Suddenly, our 20-day bamboo production is irrelevant. We cannot assemble the box without the seal. We cannot pack the box without the strap. Your entire order sits on our floor, gathering dust, held hostage by a component that costs less than five cents.

### The "Kitting" Bottleneck

This dependency becomes even more critical during the final assembly, or "kitting" phase.

Many corporate gift orders are complex sets: a bamboo cutlery set inside a canvas pouch, packed into a recycled kraft box with a custom card.

If the canvas pouch supplier delivers one week late, we cannot start packing. We can't just "pack what we have" because the cutlery needs to go *inside* the pouch. The entire assembly line stops.

In practice, this is often where lead time decisions start to be misjudged. You calculate the timeline based on the *main product*, assuming the accessories are instant. They are not. They have their own production queues, their own raw material shortages, and their own quality control failures.

### Managing the Risk: The "Parallel Start"

So, how do we prevent a $0.05 part from killing a $50,000 order?

The solution lies in decoupling the timelines. We call this the **Parallel Start Strategy**.

Instead of waiting for the final "Golden Sample" approval of the *entire* set before ordering components, we identify the "Long Lead Time" items and order them immediately.

If we know the silicone seal takes 25 days, we order it on Day 1, even if you are still tweaking the laser engraved logo on the bamboo lid. The seal is a standard part; it rarely changes. By locking in that sub-component order early, we ensure it arrives at our factory *before* the bamboo bodies are finished.

This requires trust. You have to authorize us to spend money on sub-components before the final design is 100% locked. But that small financial commitment buys you insurance against the single biggest cause of production delays: the invisible Tier 2 supplier.

Sub-component Lead Time

Tier 2 Supplier Risk

Manufacturing Bottlenecks

Supply Chain Delays

Parallel Production Strategy

Related Articles

The Real Timeline of Custom Manufacturing: A Procurement Guide for Singapore Enterprises

Stop guessing your event timeline. A 15-year supply chain expert reveals the hidden bottlenecks in custom manufacturing—from mold stabilization to multi-SKU risks.

Read More

The Hidden 'Cooling Phase': Why Bio-Composites Need 48 Hours Before Packing

A compliance consultant's warning on why rushing the packing process for wheat straw and bamboo fiber products leads to mold disasters. We explain the science of moisture migration and the mandatory stabilization period.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now