"We just want to test the market, so let's start with 500 units instead of 5,000."

It sounds like a prudent, risk-averse strategy. In the boardroom, it makes perfect sense: minimize inventory exposure, validate demand, and then scale up. But when this request hits the factory floor, it triggers a completely different set of operational logic that often results in your "agile" small order taking twice as long to produce as a full container load.

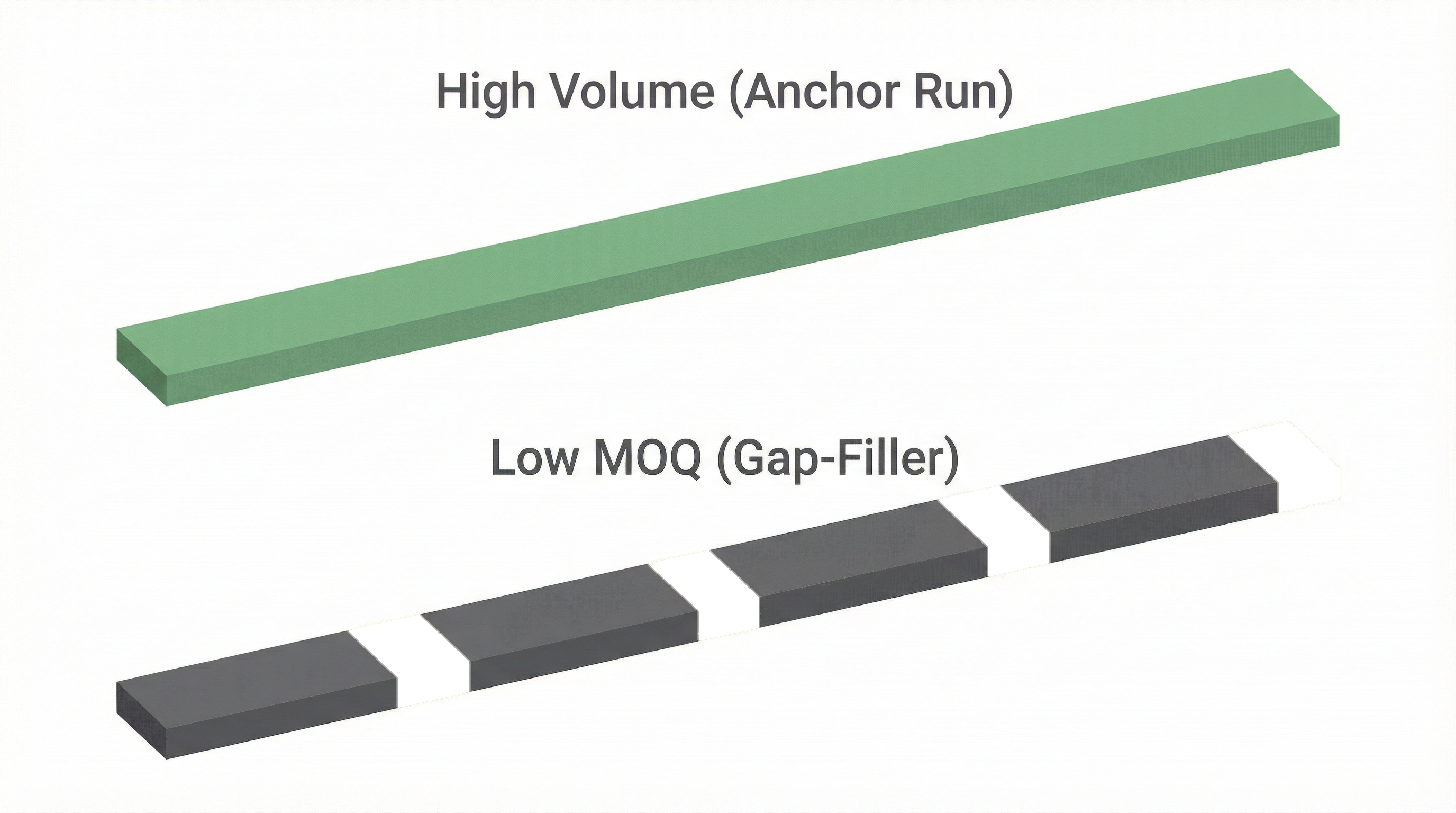

This is the **Efficiency Trap**. In manufacturing, volume is speed. When you reduce volume below a certain threshold, you don't just lose economies of scale in pricing—you lose priority in scheduling.

### The "Gap-Filler" Phenomenon

To understand why, you have to look at the factory's master schedule. A factory is a machine designed for continuous motion. Every time a machine stops to change molds, clean hoppers, or switch material colors, the factory loses money.

A 10,000-unit order allows the machine to run uninterrupted for three days. This is a "Anchor Run." It gets scheduled first because it guarantees efficiency.

A 500-unit order, however, might only take 2 hours to run. But the setup time—heating the mold, purging the screw, calibrating the injection pressure—takes the same 4 hours as it does for the big order. For the factory manager, your small order is a "net efficiency loss."

So, where does your order go? It doesn't get a prime slot. It becomes a **"Gap-Filler."**

The factory manager will hold your order in a queue, waiting for a "convenient gap" between two larger runs. They might wait until another client orders a product in the same material or color to minimize changeover time. If that big order gets delayed, or if a larger, more profitable run comes in, your "Gap-Filler" gets bumped.

This is why a standard 30-day lead time can mysteriously stretch to 45 or 60 days for low-MOQ orders. You aren't waiting for production time; you are waiting for a *setup window*.

### The Material Sourcing Bottleneck

The issue extends upstream to the raw material suppliers. Just as you have an MOQ with the factory, the factory has an MOQ with their material providers.

If you order 500 bamboo fiber bento boxes, that requires maybe 150kg of raw material. But the raw material supplier only sells pellets in 1-ton bags.

The factory now has a dilemma:

1. **Buy the full ton:** They tie up cash in 850kg of leftover material they might never use.

2. **Wait for other orders:** They hold your order until they have enough combined demand from other clients to justify buying the 1-ton bag.

Option 2 is the standard operating procedure. Your order sits in "Pending Material" status, not because the material doesn't exist, but because your volume isn't sufficient to unlock the supply chain.

### Escaping the Trap: Strategic Procurement

If you must order small volumes, you need to change your negotiation strategy. You cannot demand both "Low MOQ" and "Standard Lead Time" without giving something up.

**1. Piggyback on Standard Specs**

Ask the factory: "What are you running right now?" If they are running 50,000 units of Natural Wheat Straw for a US client, ask to tag your 500 units onto the end of that run. You sacrifice custom color, but you gain the speed of the Anchor Run.

**2. Pay for the Setup**

If you need a custom color for a small run, offer to pay a separate "Setup Fee" or "Changeover Charge." This compensates the factory for the downtime, removing the economic disincentive. It transforms your order from a "nuisance" to a "paid job," allowing the manager to schedule it firmly rather than treating it as a gap-filler.

**3. The "Blanket Order" Approach**

Commit to 5,000 units for the year but ask for delivery in batches of 1,000. You get the pricing and priority of the large volume, but the cash flow and inventory benefits of the small batches. The factory can produce all 5,000 at once (gaining efficiency) and warehouse them for you.

In practice, this is often where lead time decisions start to be misjudged. Procurement teams focus entirely on the unit price penalty of low MOQs, ignoring the hidden "time penalty" that can disrupt launch schedules. Real agility comes from understanding the factory's constraints, not just your own.

Minimum Order Quantity

Manufacturing Lead Time

Small Batch Production

Factory Scheduling

Supply Chain Efficiency

Related Articles

The Real Timeline of Custom Manufacturing: A Procurement Guide for Singapore Enterprises

Stop guessing your event timeline. A 15-year supply chain expert reveals the hidden bottlenecks in custom manufacturing—from mold stabilization to multi-SKU risks.

Read More

The Hidden 'Cooling Phase': Why Bio-Composites Need 48 Hours Before Packing

A compliance consultant's warning on why rushing the packing process for wheat straw and bamboo fiber products leads to mold disasters. We explain the science of moisture migration and the mandatory stabilization period.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now