"It's just a box with a fork, a spoon, and a napkin. Why does it take two weeks longer than ordering them loose?"

I hear this question constantly. Clients assume that because we can manufacture 50,000 forks in a day, we can also *ship* 50,000 gift sets in a day.

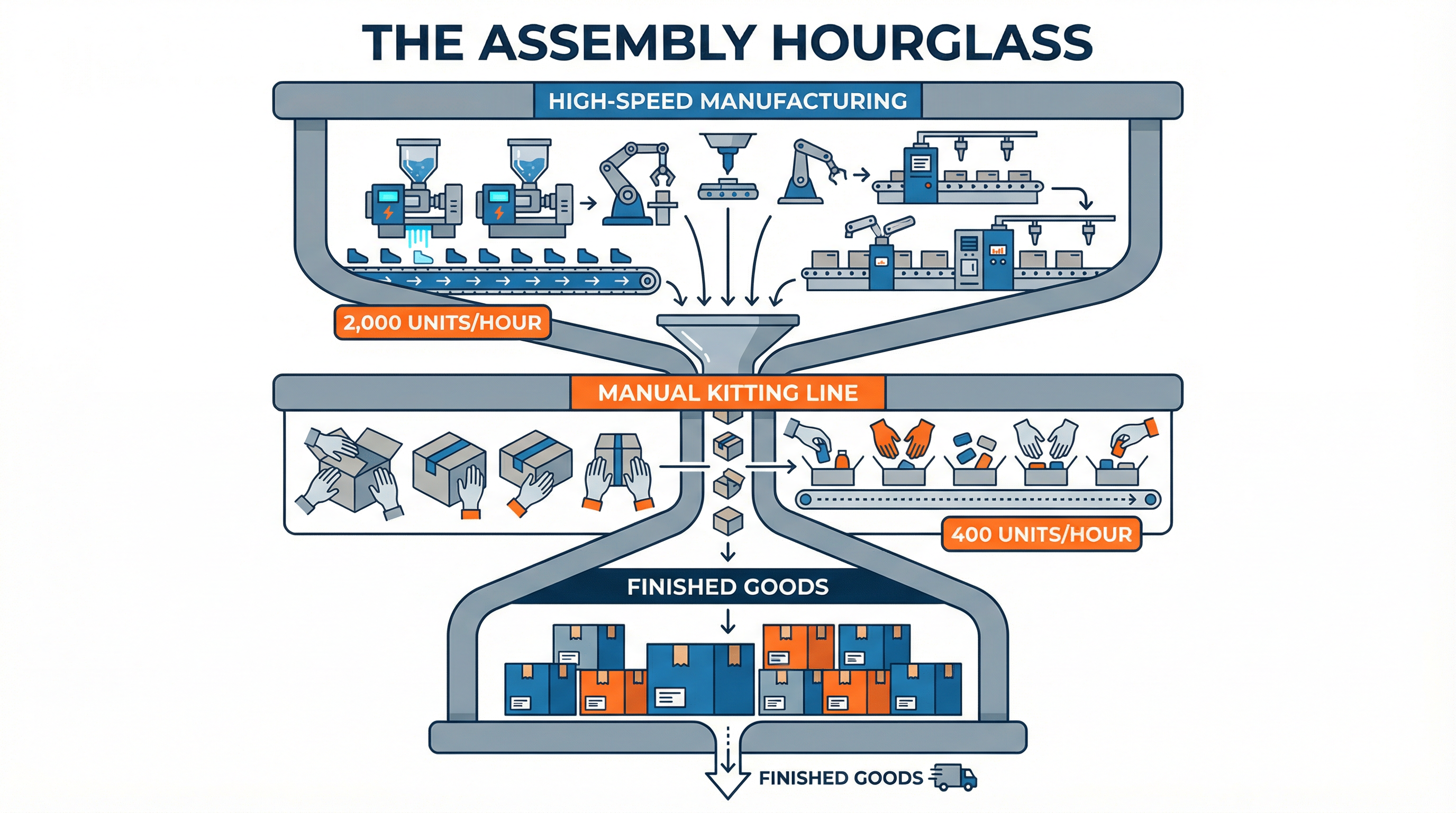

They are missing the single biggest bottleneck in custom manufacturing: **The Human Hand.**

### The Speed Mismatch: Machine vs. Human

To understand the delay, you have to look at the factory floor.

On the left side, we have **Injection Molding Machines**. They are monsters of efficiency. A 200-ton machine cycles every 15 seconds, spitting out 8 forks at a time. That is roughly **1,900 units per hour**, running 24/7 with zero breaks.

On the right side, we have the **Kitting Line**. This is a long table with 12 workers. Their job is to:

1. Fold the kraft box (5 seconds).

2. Insert the tissue paper (3 seconds).

3. Place the fork (2 seconds).

4. Place the spoon (2 seconds).

5. Roll the napkin (8 seconds).

6. Close the lid (3 seconds).

7. Apply the sticker (4 seconds).

Total time per unit: **27 seconds**.

Even with 12 workers, that line can only produce about **1,600 units per hour**—and that's assuming nobody goes to the bathroom, nobody gets tired, and the stickers don't get stuck to their fingers.

In reality, a manual kitting line operates at about **40% the speed** of the molding machines feeding it. The moment you ask for a "Gift Set," you are moving from a high-speed automated process to a low-speed manual one.

### The "Weakest Link" Phenomenon

It gets worse. In a bulk order, if the fork machine breaks, we just ship the spoons while we fix it.

In a **Kitted Order**, we cannot ship *anything* until we have *everything*.

I once had a 10,000-unit order sitting on the factory floor for 9 days. The forks were ready. The spoons were ready. The boxes were folded.

What were we waiting for? **The stickers.**

The print shop that makes the 2-inch logo stickers had a machine failure. Because the sticker is the *final seal* on the box, we couldn't close the kits. We couldn't pack them into master cartons. We couldn't stack them on pallets. The entire production line ground to a halt because of a $0.02 component.

This is the **"All-or-Nothing" Risk** of kitting. Your lead time is no longer determined by the main product; it is determined by the *slowest* component in the box.

### How to Mitigate the Delay

If you need speed, you have to design for it.

**1. The "Semi-Kit" Compromise**

Instead of a fully assembled retail box, ask for "Bulk Packed with Individual Sleeves." We can sleeve cutlery automatically at high speeds. It looks premium but skips the slow box-folding step.

**2. Parallel Packaging**

Send the packaging to us *early*. If you are printing custom boxes, approve the artwork 2 weeks *before* you approve the product. Let us build a stockpile of folded boxes so that when the forks come off the machine, we can drop them straight in.

**3. The "Sticker-Free" Design**

Avoid stickers if possible. Printing directly on the box is faster because the box factory does it automatically. Applying a sticker by hand is slow, crooked, and prone to bubbling.

In practice, this is often where lead time decisions start to be misjudged. You calculate the time to *make* the product, but you forget to calculate the time to *assemble* the experience.

Kitting Process

Manual Assembly Line

Manufacturing Bottlenecks

Packaging Lead Time

Gift Set Production

Related Articles

The Real Timeline of Custom Manufacturing: A Procurement Guide for Singapore Enterprises

Stop guessing your event timeline. A 15-year supply chain expert reveals the hidden bottlenecks in custom manufacturing—from mold stabilization to multi-SKU risks.

Read More

The Hidden 'Cooling Phase': Why Bio-Composites Need 48 Hours Before Packing

A compliance consultant's warning on why rushing the packing process for wheat straw and bamboo fiber products leads to mold disasters. We explain the science of moisture migration and the mandatory stabilization period.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now