"Production finished on Friday. Why can't we ship on Monday?"

This is the most common friction point I see between procurement teams and quality assurance departments. The goods are physically ready. They are packed in cartons. The forwarder is ready to book the space. Yet, the shipment sits on the loading dock, gathering dust for a full week.

This is not bureaucratic inefficiency. This is the **Certification Standoff**.

For any product that touches food—whether it's a bamboo fiber lunch box, a wheat straw mug, or a stainless steel cutlery set—you cannot legally or ethically ship until you have a passing test report. And contrary to popular belief, this testing cannot happen "in parallel" with the final days of production.

### The "Final Lot" Requirement

Many buyers assume we can send a sample to the lab halfway through production to save time. "Just grab one from the first batch," they say.

But reputable labs (like SGS, Intertek, or TUV) and strict compliance standards require **Final Lot Sampling**. The sample tested must be randomly drawn from the *completed* mass production run to ensure it represents the actual goods being shipped. If we test a "Day 1" sample, we aren't testing the consistency of the "Day 10" output.

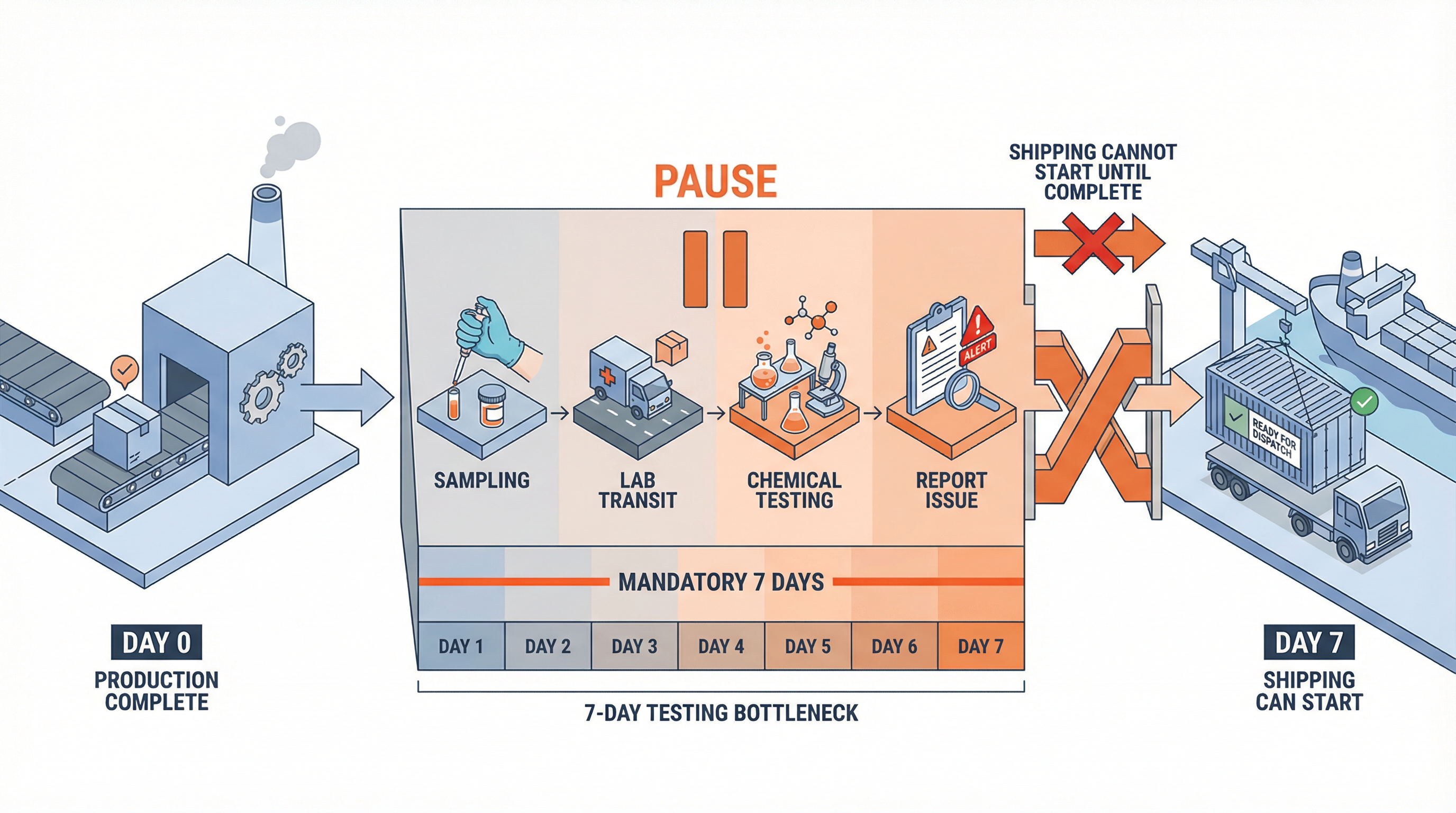

So, the timeline is rigid:

1. **Production Ends (Day 0):** The last unit comes off the line.

2. **Sampling (Day 1):** The inspector arrives, picks random boxes, and seals the sample.

3. **Transit to Lab (Day 2):** The sample travels to the testing facility (often in a different city).

4. **Lab Testing (Day 3-6):** The lab performs extraction tests (e.g., soaking the mug in acidic solution for 24 hours to check for heavy metal leaching). This chemistry cannot be rushed.

5. **Report Issuance (Day 7):** The official PDF is generated.

Only on Day 7, with the "PASS" report in hand, can we release the goods to the forwarder. If you booked the vessel for Day 3, you missed it.

### The Risk of "Shipping at Risk"

Some aggressive procurement managers ask to "Ship at Risk"—meaning, load the container while the test is ongoing, assuming it will pass.

This is a gamble with catastrophic odds. If the goods are on the water and the report comes back "FAIL" (perhaps a spike in melamine migration due to a temperature fluctuation), you have a container of toxic waste floating towards your port. You cannot import it. You cannot sell it. You have to pay to ship it back or destroy it.

The cost of a 7-day delay is friction. The cost of a failed "Ship at Risk" decision is total loss.

### Managing the "Quiet Week"

Since this week is unavoidable for compliant eco-products, the strategy isn't to eliminate it, but to plan for it.

**1. Pre-Test the Raw Material**

While we must test the final product, we can reduce the risk of failure by pre-testing the raw material pellets before production starts. This doesn't replace the final test, but it gives us 99% confidence that the chemistry is safe, making the final test a formality rather than a cliffhanger.

**2. Book "Draft" Shipping Slots**

Don't book the vessel for the day production ends. Book it for Production End + 7 Days. If the lab is fast and finishes in 5 days, you have a buffer. If you book too early, you pay "Dead Freight" charges for the cancelled booking.

**3. The "Reference Sample" Strategy**

For repeat orders of the *exact* same product and material batch, some markets allow a "Reference Report" valid for 12 months. Check if your local regulations require a fresh test for every single shipment or just an annual validation.

In practice, this is often where lead time decisions start to be misjudged. You calculate the manufacturing time but forget the validation time. The product isn't "finished" when it's made; it's finished when it's proven safe.

Lab Testing Lead Time

Food Contact Safety

SGS Report Timeline

Ship at Risk

Manufacturing Compliance

Related Articles

The Real Timeline of Custom Manufacturing: A Procurement Guide for Singapore Enterprises

Stop guessing your event timeline. A 15-year supply chain expert reveals the hidden bottlenecks in custom manufacturing—from mold stabilization to multi-SKU risks.

Read More

The Hidden 'Cooling Phase': Why Bio-Composites Need 48 Hours Before Packing

A compliance consultant's warning on why rushing the packing process for wheat straw and bamboo fiber products leads to mold disasters. We explain the science of moisture migration and the mandatory stabilization period.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now