Beyond the Buzzword: A Technical Deep Dive into Wheat Straw Biocomposites for Singapore's Sustainable B2B Sector

In Singapore’s dynamic corporate landscape, the mandate for sustainability is no longer a peripheral concern but a core strategic imperative. Driven by the ambitious Singapore Green Plan 2030 and increasing stakeholder scrutiny, corporate procurement managers, HR directors, and marketing heads are actively seeking viable, verifiable alternatives to conventional materials. The pressure to reduce the corporate environmental footprint, particularly concerning single-use and virgin plastics, has intensified.

Amidst this shift, Wheat Straw Biocomposites (WSBC) have emerged as a popular, yet frequently misunderstood, material choice for eco-friendly corporate gifts and promotional merchandise. Often simply labelled as ‘wheat straw plastic’, this material represents a significant step towards circularity by repurposing agricultural waste. However, for B2B decision-makers in Singapore, a superficial understanding is insufficient. Strategic material selection requires a technical deep dive into its composition, performance characteristics, and, crucially, its alignment with local regulatory frameworks and sustainability goals.

This authoritative guide provides a technical analysis of WSBC, moving beyond the marketing claims to offer the precise, data-driven insights necessary for informed procurement decisions in the Singapore market. We will explore the material science, manufacturing nuances, and the critical distinction between various 'biodegradable' claims, ensuring your corporate gifting programme is both impactful and compliant.

The Science of Wheat Straw Biocomposites: Composition and Manufacturing

To appreciate the environmental value of WSBC, one must first understand its fundamental composition. The term ‘wheat straw plastic’ is, in fact, a misnomer. The material is correctly defined as a biocomposite, a blend of natural lignocellulosic fibres derived from wheat straw and a synthetic or bio-based polymer matrix.

What is Wheat Straw, Really?

Wheat straw is the stalk left over after wheat grains are harvested. Historically, this agricultural residue was often burned, contributing to air pollution. By diverting it into material production, a significant waste stream is repurposed. The straw itself is rich in lignocellulose, a complex structure composed primarily of cellulose (providing strength), hemicellulose, and lignin (acting as a natural binder). These natural polymers are the key to the material’s reduced reliance on fossil-fuel-derived plastics.

The Polymer Matrix: The Critical Distinction

The performance and end-of-life profile of a WSBC product are determined by the polymer used to bind the straw fibres. The two most common matrices are:

- Polypropylene (PP): The most common choice for durable corporate gifts (e.g., mugs, lunch boxes). PP-based WSBC is highly durable, heat-resistant, and food-safe. Crucially, while the straw content reduces the overall plastic mass, the PP component is not biodegradable. It is, however, recyclable under existing PP streams, which is a key consideration for Singapore’s waste management infrastructure.

- Polylactic Acid (PLA): A bio-based and compostable polymer derived from renewable resources like corn starch or sugarcane. PLA-based WSBC is genuinely compostable, but typically requires industrial composting facilities to break down effectively. It is generally less heat-resistant than PP, making it suitable for items like disposable cutlery or cold-drink tumblers.

For Singapore B2B applications requiring longevity and repeated use, the PP-based biocomposite is often the preferred choice, offering a balance of durability and reduced virgin plastic consumption. This material choice aligns with the 'Reduce' and 'Reuse' principles of the waste hierarchy, a core tenet of the Sustainable Corporate Gifting Trends for 2025.

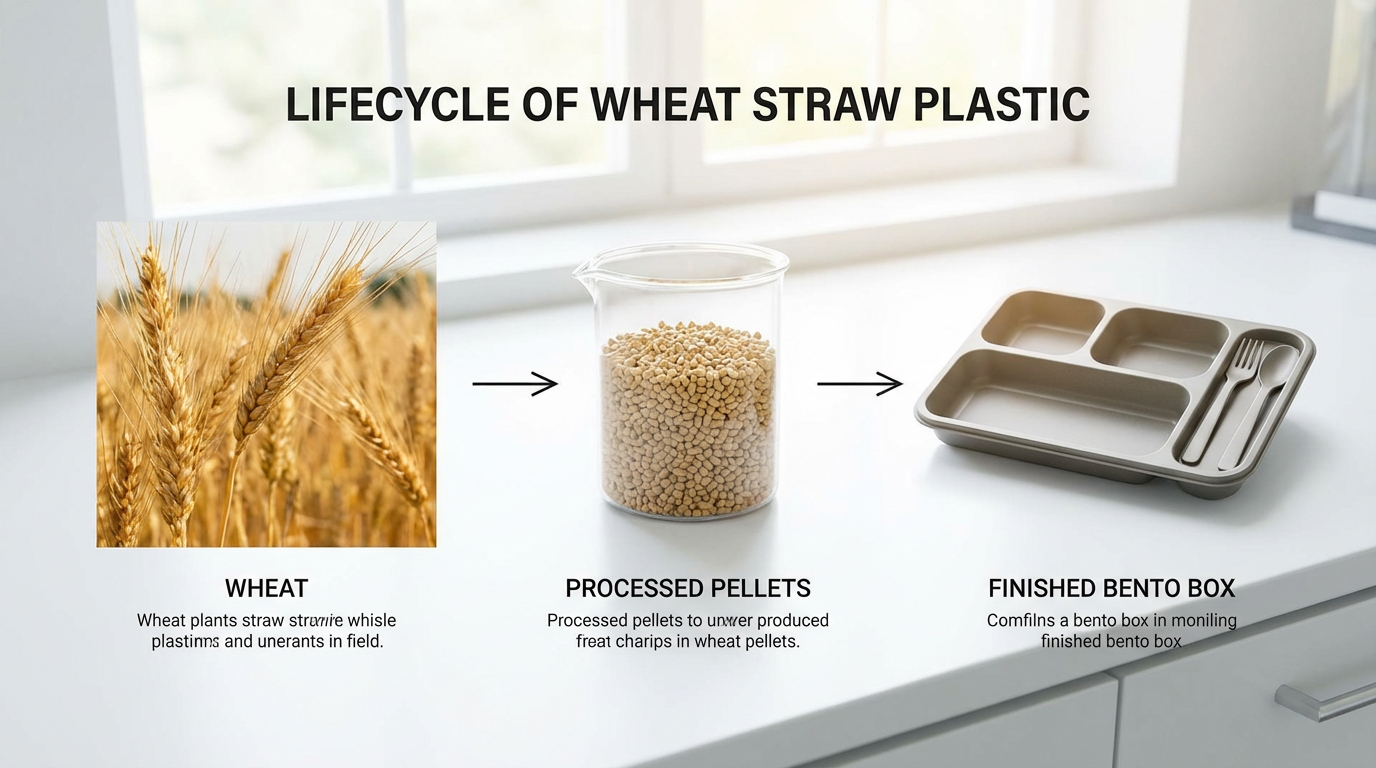

Manufacturing Process: Compounding and Injection Moulding

The production of WSBC involves a precise compounding process. First, the wheat straw is cleaned, dried, and milled into fine powder or short fibres. This material is then compounded with the molten polymer matrix (PP or PLA) in an extruder. The ratio of straw to polymer typically ranges from 30% to 50% straw content by weight. This composite pellet is then fed into standard injection moulding machines, allowing for the mass production of complex shapes, such as custom-designed corporate stationery or insulated stainless steel tumblers.

Technical Performance and Material Properties

When evaluating WSBC for corporate merchandise, procurement teams must assess its performance against conventional plastics. The inclusion of natural fibres significantly alters the material’s mechanical and thermal properties.

Mechanical and Thermal Characteristics

The lignocellulosic filler acts as a reinforcing agent, often leading to:

- Increased Stiffness (Modulus): WSBC typically exhibits a higher flexural modulus compared to the pure polymer, meaning the material is stiffer and less prone to bending. This is advantageous for items like pen casings and rigid boxes.

- Reduced Impact Strength: A trade-off of fibre reinforcement is often a slight reduction in impact strength (brittleness). However, modern compounding techniques and coupling agents mitigate this effect, ensuring products meet the necessary durability standards for daily corporate use.

- Heat Resistance: PP-based WSBC maintains the excellent heat resistance of PP, making it suitable for hot beverages and microwave use (where applicable). PLA-based WSBC has a lower heat deflection temperature, limiting its use in high-temperature applications.

Material Comparison: WSBC vs. Conventional Polymers

The following table provides a comparative overview of the most relevant material properties for B2B procurement in Singapore:

| Property | Wheat Straw Biocomposite (PP Matrix) | Virgin Polypropylene (PP) | Polylactic Acid (PLA) |

|---|---|---|---|

| Renewable Content | High (30-50% agricultural waste) | Zero (100% fossil fuel-derived) | High (100% bio-based) |

| Durability & Lifespan | Excellent; suitable for long-term reuse | Excellent; industry standard | Good; less durable than PP, sensitive to heat |

| End-of-Life Profile | Recyclable (as PP); reduced landfill mass | Recyclable (widely accepted) | Industrial Composting Required |

| Carbon Footprint | Significantly lower than Virgin PP | High | Lower than PP (dependent on production) |

| Cost (Relative) | Moderate to High (due to compounding) | Low (mass-produced commodity) | Moderate |

Safety and Customisation

For corporate gifts, product safety is paramount. Reputable suppliers ensure WSBC products are free from harmful substances like BPA (Bisphenol A) and Melamine. All food-contact items must comply with international standards (e.g., FDA, LFGB) and local Singapore Food Agency (SFA) requirements. Furthermore, WSBC is highly receptive to various branding techniques, including laser engraving and UV printing, allowing for high-quality, durable customisation that reflects the corporate brand identity.

Aligning with Singapore’s Green Plan 2030 and NEA Regulations

The adoption of WSBC is a tangible way for Singapore businesses to contribute to the national sustainability agenda. The Green Plan 2030 outlines clear targets under its 'Sustainable Living' and 'Green Economy' pillars, making material selection a strategic compliance and marketing tool.

The Waste Reduction Imperative

A key target of the Green Plan is to reduce the amount of waste sent to Semakau Landfill by 30% by 2030. By replacing 30-50% of the plastic content in a product with agricultural waste, WSBC directly supports the national goal of reducing reliance on virgin resources. For large corporations subject to the Mandatory Packaging Reporting (MPR) requirements by the National Environment Agency (NEA), choosing WSBC for corporate packaging or gifts can be factored into their waste reduction and resource efficiency plans.

Navigating the 'Biodegradable' Claim in Singapore

The term 'biodegradable' is often a source of confusion. In Singapore, the tropical climate and specific waste management infrastructure dictate what truly breaks down. The NEA has stringent guidelines, and the public is often advised that only items certified as compostable and processed in designated facilities will fully degrade. Therefore, B2B communicators must be precise:

- Clarity is Key: When marketing WSBC products, focus on the reduced virgin plastic content and the upcycling of agricultural waste, rather than solely on biodegradability, especially for PP-based items.

- Compostable PLA: If using PLA-based WSBC, ensure the product is certified to international standards (e.g., EN 13432) and communicate that it requires commercial composting, which is not yet widely available for all waste streams in Singapore.

By being transparent and technically accurate, companies can avoid 'greenwashing' accusations and build genuine trust with their stakeholders.

Conclusion: Strategic Procurement for a Sustainable Future

Wheat Straw Biocomposites offer a compelling, high-performance alternative for Singaporean businesses committed to enhancing their sustainability profile. By understanding the technical composition—the marriage of lignocellulosic fibres with a durable polymer matrix—procurement teams can confidently select products that meet both their functional requirements and their environmental objectives.

The strategic adoption of WSBC is a proactive step towards aligning with the Singapore Green Plan 2030, demonstrating corporate responsibility, and appealing to a workforce and client base that increasingly values ethical sourcing. Choosing WSBC is not just about selecting a new material; it is about investing in a circular economy solution that transforms agricultural waste into valuable, long-lasting corporate assets.

Call to Action: To explore how Wheat Straw Biocomposites can be seamlessly integrated into your next corporate gifting initiative, and to discuss customisation options that meet your brand’s exacting standards, please contact our B2B solutions team today.

Word Count: 1050 words.

Related Articles

The Pantone Illusion: Why Bio-Materials Defy Standard Color Matching

Why your wheat straw product doesn't match your Pantone chip. A factory project manager explains the physics of substrate interference in eco-friendly manufacturing.

The Truth About PLA: Industrial vs. Home Composting

PLA (Polylactic Acid) is often marketed as biodegradable, but there's a catch. We explain the critical difference between industrial and home composting and what it means for Singapore's waste management.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now