The transition to recycled polyethylene terephthalate (rPET) for corporate apparel and bags is a commendable step towards circularity. Turning waste plastic bottles into functional fabric reduces landfill mass and energy consumption. However, as a textile safety engineer, I must raise a critical point often overlooked in the rush to 'go green': chemical safety. Unlike virgin polyester, rPET feedstock comes from post-consumer waste, which introduces a variable stream of potential contaminants that must be rigorously managed.

The Legacy Contaminant Risk

Virgin polyester is synthesized from pure petrochemicals in a controlled reactor. rPET, conversely, starts its life as a beverage bottle, a food container, or even industrial packaging. If the recycling process is not strictly controlled, 'legacy substances'—chemicals absorbed by the plastic during its first life—can migrate into the new fabric. These can include heavy metals like antimony (used as a catalyst in PET production), phthalates, or non-intentionally added substances (NIAS) from labels and adhesives.

For wearable items like polo shirts or lanyards that have prolonged skin contact, the presence of these substances can cause dermatitis or allergic reactions. In the European Union, REACH regulations set strict limits on these chemicals. In Singapore, while consumer goods safety regulations exist, the specific standards for recycled textiles in corporate gifting are less codified, placing the onus on responsible brands to self-regulate.

The GRS Certification Shield

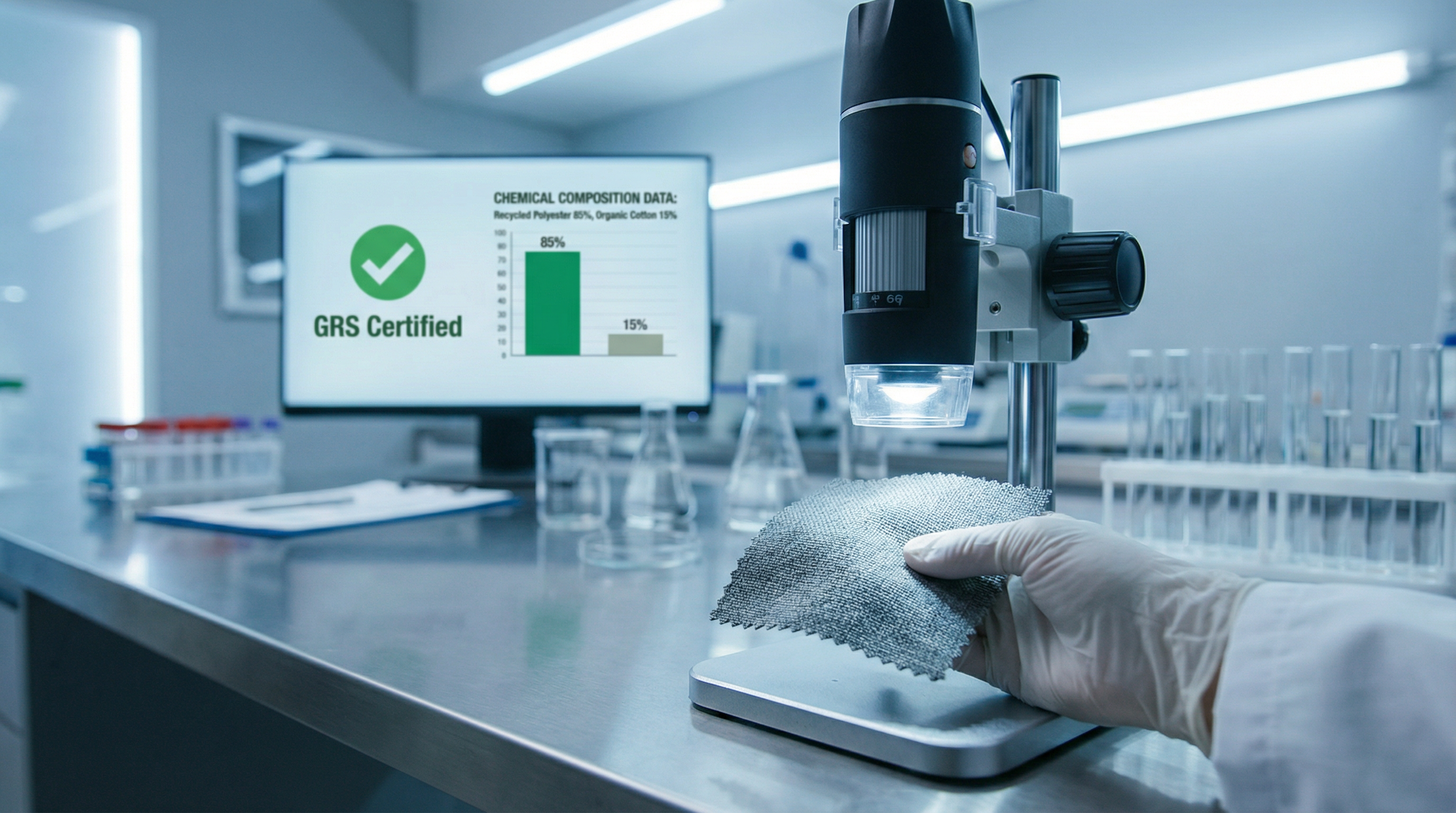

The Global Recycled Standard (GRS) is the gold standard for verifying not just the recycled content, but also the chemical safety of the final product. A GRS certificate ensures that the rPET has been processed in facilities that adhere to strict chemical management restrictions. It prohibits the use of hazardous inputs and requires regular testing of the final fabric for substances of very high concern (SVHC).

When sourcing rPET merchandise, a 'recycled' claim is insufficient. Procurement teams should demand a Transaction Certificate (TC) issued by a certification body like Control Union. This document traces the specific batch of fabric back to the certified recycler, ensuring that the chain of custody is unbroken and that the material meets safety thresholds. Without a TC, there is no guarantee that the 'rPET' bag isn't just virgin polyester with a green marketing sticker—or worse, poorly recycled plastic laden with contaminants.

Mechanical vs. Chemical Recycling

Most rPET in the market today is mechanically recycled—chopped, washed, and melted. This process is energy-efficient but limited in its ability to remove deep-seated contaminants. Chemical recycling, which breaks the polymer down into its monomers before repolymerizing, produces rPET that is chemically identical to virgin polyester and safe for even food-contact applications. While currently more expensive, chemical recycling is the future for high-sensitivity items. For standard corporate gifts, high-quality mechanical recycling with GRS certification strikes the right balance between safety, sustainability, and cost.

Related Articles

The Technical Superiority of rPET Lanyards: A B2B Guide for Sustainable Procurement in Singapore

A deep technical analysis for Singapore B2B procurement professionals on rPET lanyards. We examine the material science, advanced weaving processes, and strategic alignment with the Singapore Green Plan 2030, proving rPET's technical superiority and sustainability over virgin polyester.

The Unrivalled Durability of UV Printing for Corporate Gifts in Singapore's Climate

For Singapore's B2B sector, selecting the right branding method for corporate gifts is critical. This deep-dive compares UV printing and screen printing, focusing on how UV technology offers superior durability, environmental compliance, and aesthetic quality, especially against the challenges of the tropical climate.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now