The Unrivalled Durability of UV Printing for Corporate Gifts in Singapore's Climate

In Singapore’s competitive B2B landscape, a corporate gift is more than a token of appreciation; it is a tangible extension of your brand identity. For procurement managers, HR directors, and marketing heads, the longevity and aesthetic quality of the branding are paramount. A logo that fades, scratches, or peels prematurely in the challenging tropical climate reflects poorly on the gifting company. This is why the choice of printing technology—specifically, the comparison between modern UV printing and traditional screen printing—is a critical procurement decision.

This technical analysis delves into why UV (Ultraviolet) printing is rapidly becoming the preferred method for customising premium corporate gifts, offering superior durability, precision, and environmental compliance that aligns with Singapore’s progressive business standards and the Singapore Green Plan 2030.

The Technical Superiority of UV Curing Technology

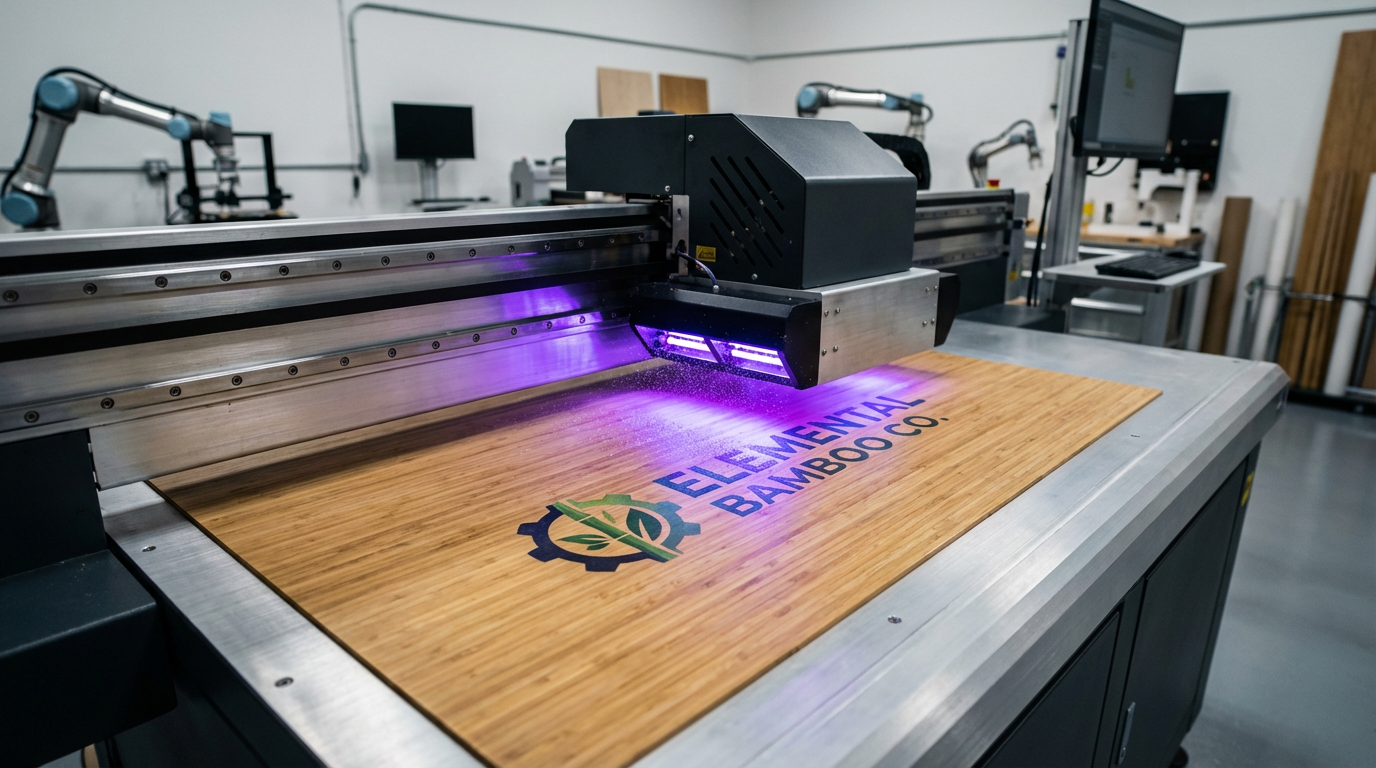

The fundamental difference between UV printing and screen printing lies in the curing process. Traditional screen printing relies on solvent-based inks that dry through evaporation, a process heavily influenced by ambient temperature and humidity. UV printing, conversely, uses a photochemical process that is instantaneous and climate-independent.

How UV Printing Achieves Instantaneous Durability

UV inks are composed of monomers, oligomers, and photoinitiators. When exposed to high-intensity UV light (typically from LED lamps), the photoinitiators instantly trigger a polymerisation reaction. This process transforms the liquid ink into a solid, durable film that is chemically bonded to the substrate. This instantaneous curing offers several key advantages:

- Superior Adhesion: The chemical cross-linking creates a robust bond with a wide range of materials, including plastics, metals, glass, wood, and ceramics. This bond is far less susceptible to mechanical abrasion or chemical degradation than the physical adhesion of solvent-based inks.

- Zero Solvent Evaporation: Since the ink cures instantly without relying on solvent evaporation, the print layer is 100% solid. This eliminates the risk of shrinkage, cracking, or bubbling that can occur with solvent inks as they dry, especially on non-porous surfaces.

- Thickness and Texture: UV printing allows for precise control over ink deposition, resulting in a thin, yet highly opaque and vibrant layer. Modern UV printers can also achieve tactile, raised-print effects (known as 3D or embossed UV printing), adding a premium feel to the gift.

The Screen Printing Challenge: Humidity and Substrate Limits

Screen printing, while cost-effective for high-volume, simple designs, faces significant technical hurdles, particularly in a high-humidity environment like Singapore (average relative humidity often exceeds 80%).

- Drying Time Dependency: Solvent-based inks require a controlled environment for proper drying. High humidity can slow the evaporation rate, leading to incomplete curing, which compromises the print's hardness and resistance to scratching.

- Ink Layer Vulnerability: The ink layer in screen printing is often thicker, making it more prone to cracking or peeling over time, especially when applied to flexible or curved surfaces. The print's durability is highly dependent on the correct formulation of the solvent and the precise control of the drying oven, which can be inconsistent.

- Material Restrictions: Screen printing struggles with certain non-porous materials like treated metals or glass without extensive pre-treatment, as the ink's physical bond is weaker.

The Singapore Climate Factor: A Test of Endurance

Singapore’s climate—characterised by high heat and relentless humidity—is a severe stress test for any branded product. Corporate gifts, such as stainless steel tumblers or bamboo fibre notebooks, are constantly exposed to moisture and temperature fluctuations. This environment accelerates the degradation of inferior printing methods.

Resistance to Moisture and Abrasion

The polymerised structure of UV ink is inherently waterproof and highly resistant to chemical solvents, including common cleaning agents. This is crucial for items like reusable coffee cups or water bottles, which undergo frequent washing. In contrast, the binder in many screen-printed inks can soften or degrade when exposed to prolonged moisture, leading to colour bleed or loss of adhesion.

Furthermore, the high-traffic nature of corporate life—gifts being tossed into bags, handled daily, and exposed to friction—demands high abrasion resistance. UV-cured prints, due to their hard, cross-linked surface, consistently outperform screen-printed designs in standardised rub-tests, ensuring the corporate logo remains crisp and intact for the entire lifecycle of the gift.

Strategic Procurement: Comparing UV and Screen Printing

For procurement professionals, the decision often boils down to cost, quality, and turnaround time. While the initial unit cost of UV printing may be marginally higher than screen printing for very large volumes, the total cost of ownership (TCO) and brand risk mitigation favour UV technology.

Comparison of Key Factors for Corporate Gifting

| Feature | UV Printing (LED Cured) | Screen Printing (Solvent/Heat Cured) |

|---|---|---|

| Durability in Humid Climate | Excellent. Instantaneous chemical cure is unaffected by humidity. Highly resistant to moisture and abrasion. | Fair to Good. Curing process is sensitive to humidity, risking incomplete drying and reduced adhesion over time. |

| Resolution & Detail | Superior. Capable of photographic quality, fine lines, and variable data printing (VDP). | Limited. Best for solid colours and simple graphics. Fine detail can be lost due to mesh size. |

| Environmental Impact (VOCs) | Low/Zero. UV inks are virtually free of Volatile Organic Compounds (VOCs), aligning with NEA standards. | Moderate to High. Solvent-based inks release VOCs during the drying process, posing environmental and workplace health concerns. |

| Substrate Versatility | High. Excellent adhesion on almost all materials (metal, glass, plastic, wood, leather) without extensive pre-treatment. | Moderate. Requires specific ink types and pre-treatments for non-porous materials. |

| Turnaround Time | Fast. Instant curing eliminates drying time, speeding up production and reducing bottlenecks. | Slow. Requires significant drying/curing time between colour applications and before packaging. |

Sustainability and Compliance in the Singapore Context

The shift towards UV printing is not just a matter of durability; it is a move towards more sustainable and compliant manufacturing, a priority for Singaporean businesses committed to Corporate Social Responsibility (CSR) and the national sustainability agenda.

Aligning with the Singapore Green Plan 2030

The Green Plan 2030 sets ambitious targets for sustainable development, influencing procurement policies across government and the private sector. A key component of this is reducing pollution and waste. UV printing offers a significant advantage here:

- Zero VOC Emissions: Unlike solvent-based screen printing, UV inks contain virtually no Volatile Organic Compounds (VOCs). This aligns with the National Environment Agency (NEA) guidelines for air quality and demonstrates a commitment to reducing the environmental footprint of the supply chain.

- Reduced Waste: The precise, digital nature of UV printing results in less material waste, fewer rejected prints, and no need for the harsh chemical wash-up solvents required for screen printing screens.

- Energy Efficiency: Modern UV-LED curing systems consume significantly less energy than traditional mercury-vapour UV lamps or heat-intensive drying ovens used in screen printing, contributing to a lower carbon footprint in the manufacturing process.

By choosing UV-printed corporate gifts, companies are not only ensuring a high-quality, durable product but are also making a demonstrable commitment to green procurement practices, a factor increasingly valued by stakeholders and partners in the Singapore B2B ecosystem.

Beyond Durability: Aesthetic Precision and Customisation

In addition to its resilience, UV printing provides unparalleled aesthetic flexibility, which is vital for sophisticated corporate branding. The technology allows for high-resolution, full-colour (CMYK) printing, often including white ink and clear varnish in a single pass. This capability is essential for:

- Vibrant Colour Reproduction: UV inks are opaque and sit on the surface of the substrate, resulting in colours that are exceptionally vibrant and true to the brand's Pantone specifications, even on dark or transparent materials.

- Variable Data Printing (VDP): UV printing is a digital process, meaning every single gift can be customised with a unique name, serial number, or QR code without slowing down production. This level of personalisation is impossible with the fixed screens of traditional printing methods.

- Premium Finishes: The ability to print a clear, glossy, or matte varnish selectively (spot UV) adds a layer of sophistication and protection, enhancing the perceived value of the corporate gift. For more information on selecting the right branding method for different eco-materials, refer to our guide on Custom Branding Eco-Products.

Conclusion: Securing Your Brand's Legacy with UV Printing

For Singapore’s discerning corporate buyers, the decision between UV printing and screen printing is a choice between short-term savings and long-term brand integrity. In a climate that tests the limits of material science, UV printing offers a technically superior, environmentally responsible, and aesthetically precise solution.

The polymerised, instant-cured bond of UV ink ensures that your corporate logo will withstand the humidity, abrasion, and daily use that define the life of a premium corporate gift. By opting for UV technology, you are investing in a durable, high-quality finish that protects your brand image and aligns with the growing demand for sustainable procurement practices in Singapore.

Ready to elevate your corporate gifting programme with branding that lasts? Explore our full catalogue of eco-friendly corporate gifts and discuss your customisation needs with our technical specialists today.

Related Articles

Surviving the 'End-of-Year' Gifting Crunch: A Timeline for Singaporean HR Departments

A comprehensive timeline and strategy guide for Singaporean HR Procurement Specialists to navigate the end-of-year corporate gifting rush, covering planning from Q3 to Chinese New Year.

Minimum Order Quantity for Custom Eco-Friendly Tableware Singapore | Procurement Guide

Confused by MOQ for custom eco cutlery and tableware? We decode minimum order quantities, trade-offs, and procurement strategies for Singapore F&B and Corporate Gifting. Read the expert guide.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now