In the world of metallurgy, not all stainless steel is created equal, especially when subjected to the unique atmospheric conditions of Singapore. As a material scientist specializing in corrosion resistance, I frequently encounter corporate gifts—thermal flasks, cutlery sets, and metal straws—that show unsightly pitting and rust spots within months of distribution. The culprit is almost invariably the specification of Grade 304 stainless steel instead of the more robust Grade 316. For procurement teams in Singapore, understanding the microscopic differences between these alloys is not just academic; it is a matter of brand reputation preservation.

The Chemistry of Corrosion Resistance

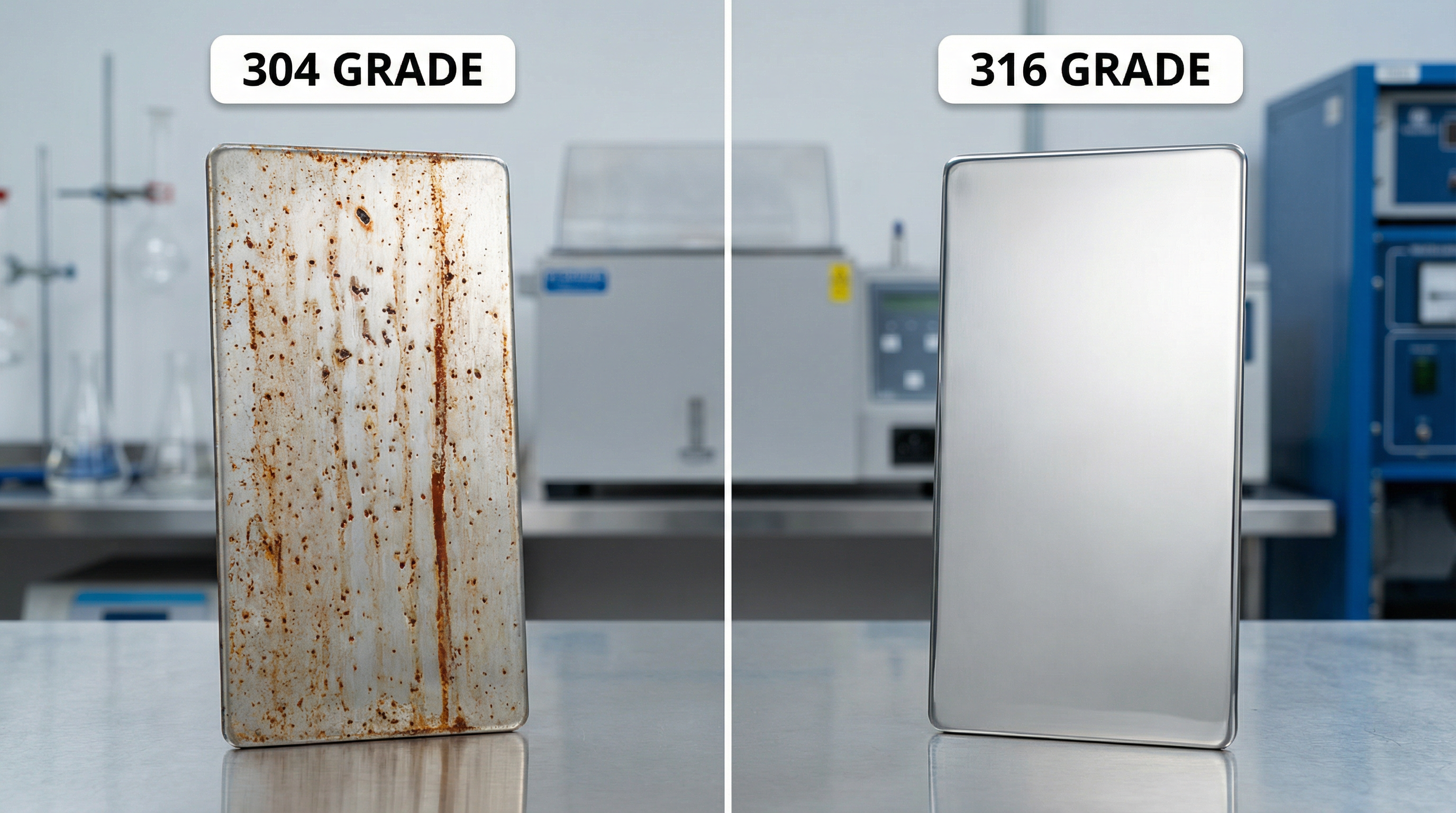

At a fundamental level, both 304 and 316 stainless steels are austenitic alloys, meaning they share a similar crystalline structure that provides toughness and ductility. However, their chemical composition diverges in one critical element: Molybdenum. Grade 304, the industry standard for general cookware, typically contains 18% chromium and 8% nickel. It relies on the chromium to form a passive oxide layer that shields the iron from rusting. In dry or continental climates, this is sufficient.

Grade 316, often referred to as 'marine grade,' introduces 2-3% molybdenum into the matrix. This addition drastically alters the alloy's resistance to chloride ions—the primary corrosive agent found in sea salt and sweat. In a high-humidity, coastal environment like Singapore, chloride ions are omnipresent in the air. When these ions settle on a 304 surface, they can penetrate the passive chromium oxide layer, creating microscopic pits that eventually bloom into visible rust. Molybdenum fortifies this passive layer, making it significantly harder for chlorides to breach.

Singapore's Atmospheric Challenge

Singapore's average relative humidity hovers around 84%, often spiking to 100% during monsoon seasons. Combined with our proximity to the sea, the air carries a higher salinity load than inland cities. A study exposing standard 304 steel to Singapore's outdoor environment showed visible pitting corrosion within 6 to 12 months. In contrast, 316 samples remained pristine for over 5 years under identical conditions. For a corporate gift meant to last years, this difference is the line between a cherished item and landfill.

Cost vs. Longevity Analysis

Procurement officers often balk at the price premium of 316 stainless steel, which can be 30-40% higher than 304 due to the cost of molybdenum and nickel. However, this upfront cost must be weighed against the 'Cost of Poor Quality' (COPQ). If a batch of branded thermal flasks begins to rust after six months, the damage to the brand's image—signaling cheapness and lack of foresight—far outweighs the initial savings. We recommend a simple rule: for items that will be used daily or exposed to outdoor elements (like travel mugs or lunch boxes), 316 is mandatory. For desk-bound items like pen holders, 304 may suffice.

Verifying Your Supply

Visually, 304 and 316 are indistinguishable. To ensure you are getting what you paid for, request a Positive Material Identification (PMI) test report from your supplier. This handheld X-ray fluorescence (XRF) test provides an instant readout of the alloy's chemical composition. At EcoSential Works, every batch of our premium metalware undergoes random PMI testing to guarantee the molybdenum content meets the 2% minimum threshold for Grade 316 certification.

Related Articles

The Technical Superiority of rPET Lanyards: A B2B Guide for Sustainable Procurement in Singapore

A deep technical analysis for Singapore B2B procurement professionals on rPET lanyards. We examine the material science, advanced weaving processes, and strategic alignment with the Singapore Green Plan 2030, proving rPET's technical superiority and sustainability over virgin polyester.

The Unrivalled Durability of UV Printing for Corporate Gifts in Singapore's Climate

For Singapore's B2B sector, selecting the right branding method for corporate gifts is critical. This deep-dive compares UV printing and screen printing, focusing on how UV technology offers superior durability, environmental compliance, and aesthetic quality, especially against the challenges of the tropical climate.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now