In the sweltering heat of a Singaporean hawker center, where a bowl of Bak Chor Mee or Laksa is served piping hot, the choice of takeaway packaging is not merely an environmental decision—it is a matter of structural integrity and consumer safety. As a Material Scientist specializing in biopolymers, I have observed a recurring failure in the adoption of sustainable packaging: the mismatch between material thermal properties and local culinary habits. Specifically, the widespread confusion between Polylactic Acid (PLA) and Sugarcane Bagasse often leads to disastrous results for businesses serving hot food.

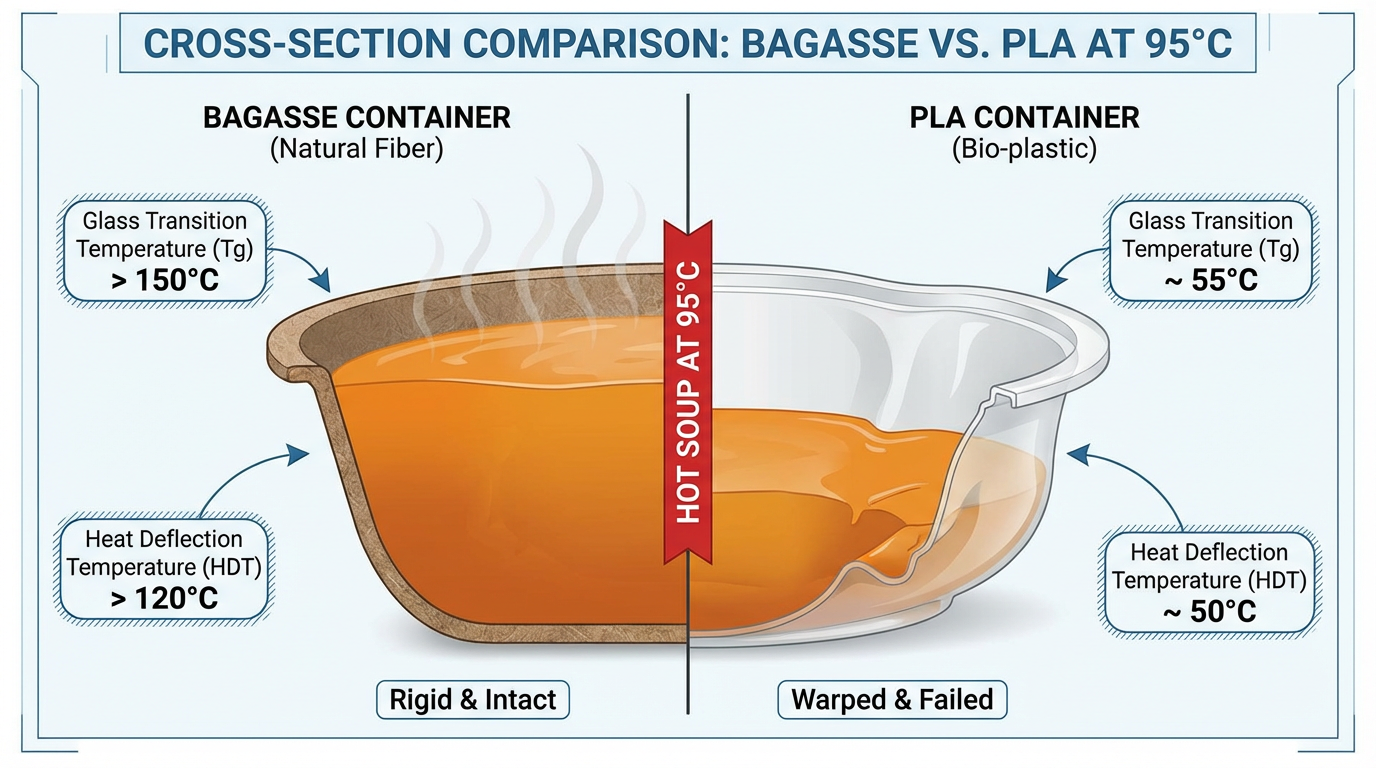

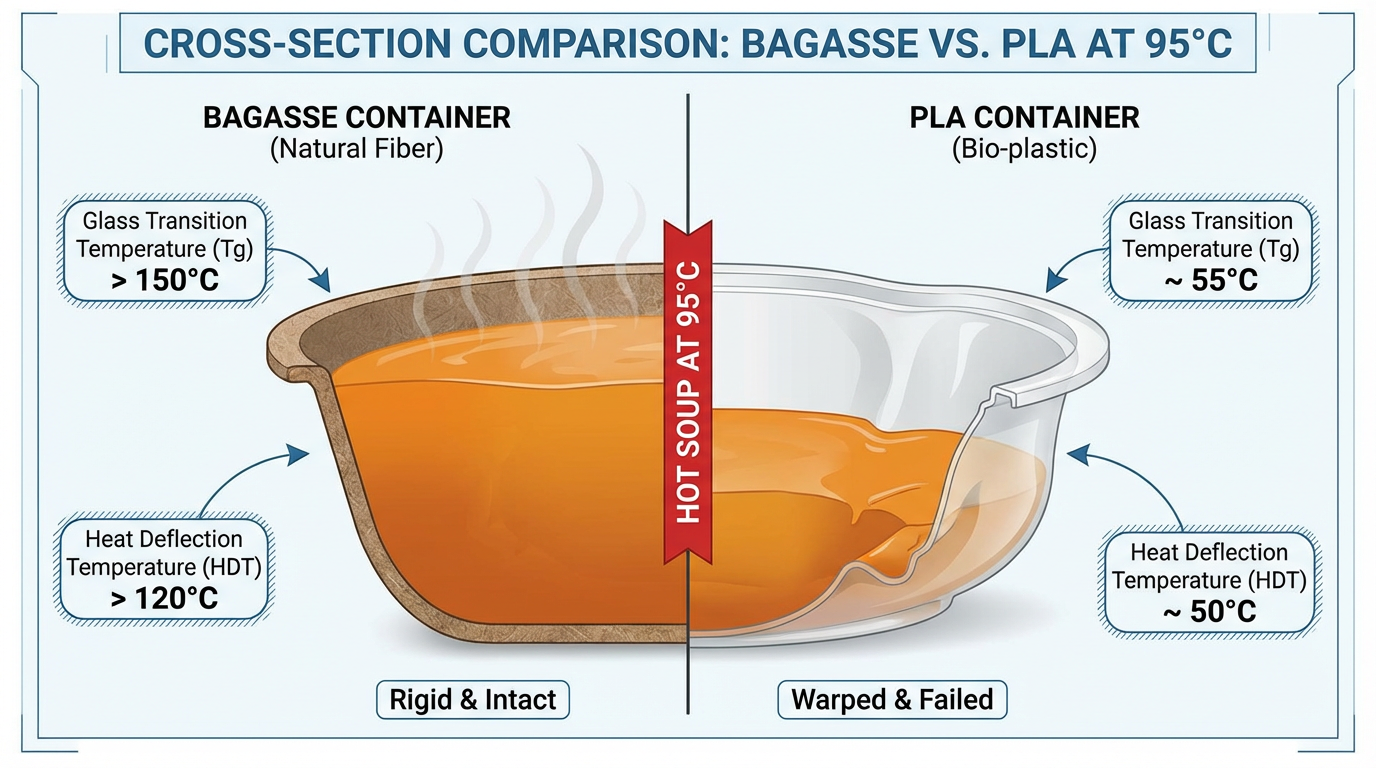

The core of this issue lies in the Glass Transition Temperature (Tg). This is the temperature range where a polymer transitions from a hard, glassy material to a soft, rubbery state. For standard amorphous PLA, the Tg is relatively low, typically around 55°C to 60°C. In contrast, freshly cooked hawker food often exceeds 85°C, with soups and gravies retaining heat near boiling point for several minutes. When hot food contacts a standard PLA container, the material instantly exceeds its Tg, causing rapid molecular chain mobility. Visually, this manifests as warping, shrinking, and in severe cases, total structural collapse.

Sugarcane Bagasse, however, operates on a different structural principle. It is not a thermoplastic polymer but a fibrous pulp molded into shape. Its heat resistance is derived from the physical entanglement of cellulose fibers and the lignin binder, rather than a polymer melt phase. High-quality bagasse packaging can withstand temperatures up to 200°C (for short periods) without losing rigidity. This makes it inherently superior for the high-heat, high-humidity environment of Singapore's food landscape.

The Physics of Thermal Deformation

To understand why PLA fails, we must look at its Heat Deflection Temperature (HDT). HDT is the temperature at which a polymer or plastic sample deforms under a specified load. For unmodifed PLA, the HDT is dangerously close to its Tg. While crystallized PLA (C-PLA) exists and offers higher heat resistance (up to 85°C), it is often opaque, more brittle, and significantly more expensive. Many suppliers, in a bid to cut costs, supply amorphous PLA or blends with insufficient crystallization, leading to the 'melting' phenomenon often reported by dissatisfied F&B operators.

Bagasse's fibrous network acts as a natural insulator. When hot soup is poured into a bagasse bowl, the fibers absorb a microscopic amount of moisture which then evaporates, creating a slight cooling effect at the interface, while the bulk material remains rigid. There is no 'melting point' in the traditional sense until the material begins to char, which occurs at temperatures far above food service requirements.

| Property | Standard PLA | Sugarcane Bagasse | Implication for Hawker Food |

|---|---|---|---|

| Glass Transition Temp (Tg) | ~55°C - 60°C | N/A (Fibrous Material) | PLA softens upon contact with hot noodles/soup. |

| Max Service Temp | ~40°C - 50°C | ~100°C (Water) / 120°C (Oil) | Bagasse handles boiling liquids safely. |

| Microwaveability | No (Deforms) | Yes (Safe) | Bagasse allows for reheating, essential for takeaway. |

Chemical Migration and Safety

Another critical, often overlooked aspect is chemical migration. When a polymer like PLA is heated near its degradation point, the risk of oligomer migration into the food matrix increases. While PLA is generally recognized as safe (GRAS), the structural breakdown can release micro-particles into the food. Bagasse, being a natural fiber, does not suffer from this polymer leaching. However, it is crucial to source PFAS-free bagasse. Historically, some molded fiber products used per- and polyfluoroalkyl substances (PFAS) for oil resistance. At EcoSential Works, we strictly utilize PFAS-free bagasse solutions, achieving oil resistance through advanced bio-based coatings that do not compromise the material's compostability or safety.

For F&B businesses in Singapore, the choice is clear. If you are serving cold salads, juices, or desserts, PLA is a fantastic, transparent option that showcases the freshness of the product. But for the heart of our culinary culture—the Char Kway Teow, the Fish Soup, the Chicken Rice—Bagasse is the only scientifically sound sustainable option. It withstands the heat, retains its shape, and ensures that the sustainability journey doesn't end in a spilled meal and a frustrated customer.

Are you struggling with packaging that warps under heat? Contact our technical team to test our high-heat resistant bagasse samples.

Question: Why does my eco-friendly plastic container melt when I put hot soup in it?

The 'eco-friendly plastic' is likely standard Polylactic Acid (PLA), which has a low heat resistance of around 50-60°C. Hot soup typically exceeds 80°C, causing the PLA to pass its Glass Transition Temperature and deform. For hot foods, molded fiber options like Sugarcane Bagasse are recommended as they can withstand temperatures up to 100°C without losing structural integrity.

Related Articles

The Technical Superiority of rPET Lanyards: A B2B Guide for Sustainable Procurement in Singapore

A deep technical analysis for Singapore B2B procurement professionals on rPET lanyards. We examine the material science, advanced weaving processes, and strategic alignment with the Singapore Green Plan 2030, proving rPET's technical superiority and sustainability over virgin polyester.

The Unrivalled Durability of UV Printing for Corporate Gifts in Singapore's Climate

For Singapore's B2B sector, selecting the right branding method for corporate gifts is critical. This deep-dive compares UV printing and screen printing, focusing on how UV technology offers superior durability, environmental compliance, and aesthetic quality, especially against the challenges of the tropical climate.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now