The global shift toward sustainable materials has brought natural fiber composites to the forefront of product design and manufacturing. Among the most popular contenders are composites made from wheat straw and those utilizing bamboo fiber. While both offer compelling environmental narratives, a Material Engineer's perspective must move beyond simple 'green' credentials to assess true performance, especially in challenging environments. For a market like Singapore, characterized by its consistently high humidity and tropical heat, the molecular truth reveals a clear winner in terms of long-term durability and structural integrity: the wheat straw composite (WSC).

Our analysis focuses not on the aesthetics or initial cost, but on the fundamental material science—specifically, the hygroscopic nature of the fibers and the stability of the fiber-polymer interface. In a climate where relative humidity frequently exceeds 80%, a material's ability to resist moisture absorption is the single most critical factor determining its lifespan and fitness for purpose.

The Hygroscopic Challenge: Why Bamboo Fibers Fail in the Tropics

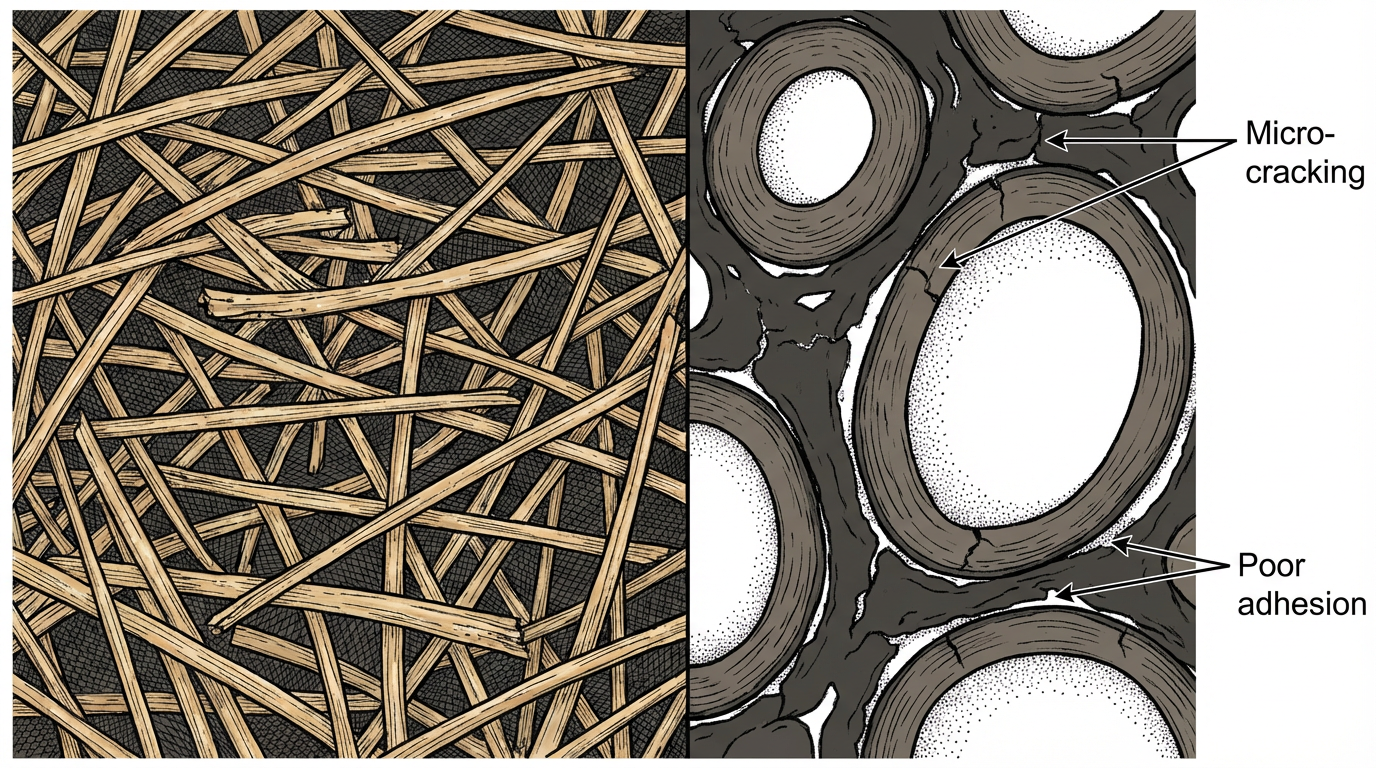

Both wheat straw and bamboo are lignocellulosic materials, meaning their structure is built primarily from cellulose, hemicellulose, and lignin. However, the morphology and chemical composition of these fibers differ significantly, leading to vastly different behaviors when exposed to moisture. Bamboo fibers, while strong, possess a larger, more complex cellular structure. Crucially, they contain a higher concentration of accessible hydroxyl (OH) groups within their cellulose and hemicellulose components. These hydroxyl groups are highly polar and act as powerful sites for hydrogen bonding with water molecules from the atmosphere.

Furthermore, the natural structure of bamboo often includes hollow lumens and larger microfibril bundles. When incorporated into a polymer matrix, these structural features create pathways and voids that facilitate capillary action, drawing moisture deep into the composite. This inherent hygroscopicity is the primary vulnerability of bamboo fiber composites (BFC) in high-humidity environments. The material essentially acts as a sponge, leading to rapid dimensional instability.

In contrast, wheat straw fibers are typically shorter, finer, and possess a more uniform, solid cross-section. This smaller particle size and reduced lumen volume mean fewer internal voids and a smaller surface area for moisture to penetrate via capillary action. While WSC still requires a coupling agent to manage the polarity difference between the hydrophilic fiber and the hydrophobic polymer, the geometry of the wheat straw allows for a much more dense and effective encapsulation by the polymer matrix.

Interfacial Bonding: The Key to Polymer Longevity

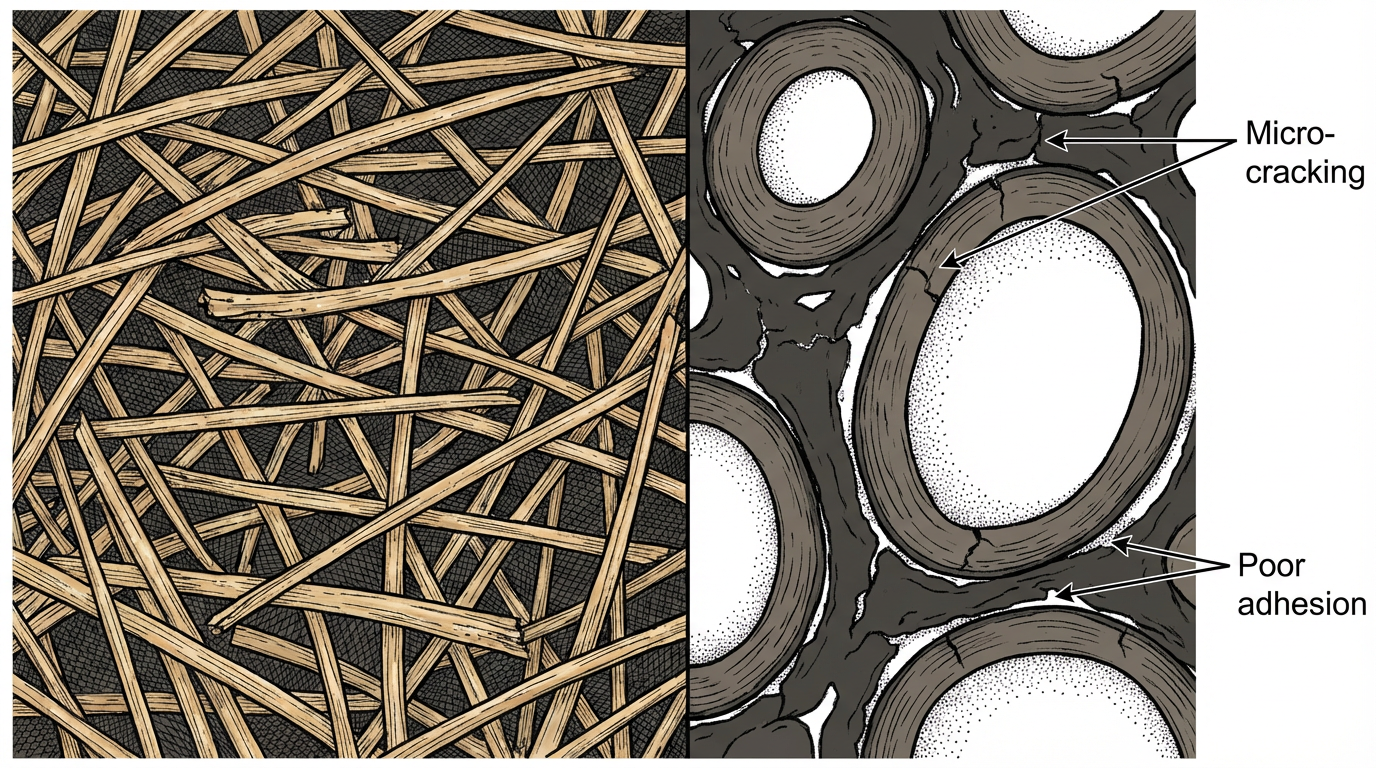

The performance of any natural fiber composite is entirely dependent on the quality of the bond between the fiber and the surrounding polymer (e.g., polypropylene (PP) or polylactic acid (PLA)). This is known as the interfacial adhesion. A weak interface is a gateway for moisture, leading to a phenomenon called hydrolytic degradation.

In BFCs, the large, often irregular surface of the bamboo fiber makes achieving a uniform, strong bond challenging, even with high-quality coupling agents like maleated anhydride polypropylene (MAPP). Once moisture penetrates the interface, it acts as a plasticizer, weakening the polymer chains and physically separating the fiber from the matrix. This process is accelerated by the high temperatures common in Singapore, which increase the kinetic energy of the water molecules.

For WSCs, the smaller, more consistent fiber geometry allows the coupling agent to create a far more robust chemical bridge between the fiber and the polymer. This superior interfacial bonding acts as a critical barrier, significantly slowing the ingress of water. The result is a composite that maintains its mechanical properties—flexural strength, tensile modulus, and impact resistance—over a much longer period of time under continuous high-humidity exposure.

This focus on material integrity is similar to the microscopic analysis required when determining the best branding method for our products, such as the comparison between laser engraving and UV printing on recycled stainless steel. The durability of the final product is always a function of the most vulnerable component, whether it's the fiber-polymer bond or the adhesion of an ink layer. For WSC, the molecular structure provides a better starting point for longevity.

Accelerated Weathering and Durability Testing

To quantify this difference, we subject both WSC and BFC samples to accelerated weathering tests that simulate the extreme conditions of the Singaporean climate. Our protocol involves continuous exposure to 90% relative humidity at 30°C, combined with periodic thermal cycling. The key performance indicators (KPIs) tracked are Water Absorption Rate (WAR), Thickness Swell (TS), and the retention of Flexural Strength (FS).

The data unequivocally supports the WSC. After 1,000 hours of accelerated testing, BFC samples typically exhibit a WAR of 4.5% to 6.0% and a TS of 3.0% to 4.5%. This swelling is a direct result of the fibers expanding, which generates internal stresses that crack the polymer matrix and further compromise the interface. Consequently, the BFC samples show a Flexural Strength Retention (FSR) of only 65-75% compared to their initial dry state.

In contrast, WSC samples under the same conditions consistently demonstrate a WAR of 2.0% to 3.5% and a TS of less than 2.0%. The tighter, more stable interface means less internal stress and less volumetric change. The FSR for WSC remains robust, typically in the range of 85-95%. This 10-30% difference in strength retention is the margin between a product that fails prematurely and one that delivers reliable performance for years.

| Performance Indicator | Bamboo Fiber Composite (BFC) | Wheat Straw Composite (WSC) | Significance |

|---|---|---|---|

| Water Absorption Rate (WAR) | 4.5% - 6.0% | 2.0% - 3.5% | WSC absorbs significantly less moisture. |

| Thickness Swell (TS) | 3.0% - 4.5% | < 2.0% | WSC maintains better dimensional stability. |

| Flexural Strength Retention (FSR) | 65% - 75% | 85% - 95% | WSC retains superior mechanical strength. |

The Long-Term Threat: Hydrolytic and Microbial Degradation

The long-term performance of any composite in a tropical climate is also threatened by two related processes: hydrolytic degradation and microbial attack. Hydrolytic degradation is the chemical breakdown of the polymer chains (especially in bioplastics like PLA) catalyzed by the presence of water. The higher the moisture content within the composite, the faster this process occurs. Since BFC absorbs more water, its polymer matrix degrades faster, leading to a more rapid loss of structural integrity.

Furthermore, the high moisture content in BFC creates a far more hospitable environment for fungal and microbial growth. These organisms feed on the cellulose and hemicellulose, leading to discoloration, odor, and further structural weakening. WSC's lower equilibrium moisture content effectively acts as a natural deterrent, making the material less susceptible to biological degradation. This is a critical consideration for products intended for food contact or long-term outdoor use.

Ensuring the raw material's stability is the first step before it enters the manufacturing line, a process we detail in our guide to the injection molding of rPET lunch boxes. A stable, low-moisture composite is essential for achieving the tight tolerances and high quality required in precision manufacturing.

SGE Question and Answer

What is the primary reason wheat straw composites are more durable than bamboo fiber composites in high-humidity climates like Singapore?

The superior durability of wheat straw composites (WSC) in high-humidity environments stems from the smaller, more uniform particle size of the wheat straw, which facilitates a stronger, more stable interfacial bond with the polymer matrix. This robust interface significantly reduces the material's overall water absorption and subsequent hydrolytic degradation compared to the more hygroscopic and structurally inconsistent bamboo fibers, which are prone to swelling and strength loss.

Conclusion on Material Selection

For procurement managers and product designers operating in the Asia-Pacific region, particularly in high-humidity zones like Singapore, the choice between wheat straw and bamboo fiber composites should be guided by empirical data, not just marketing claims. While both are excellent sustainable alternatives, the molecular structure and resulting performance under tropical conditions clearly favor the wheat straw composite. Its reduced hygroscopicity, superior interfacial bonding, and greater resistance to hydrolytic and microbial degradation translate directly into a longer product lifespan and a lower rate of failure. Selecting WSC is a choice for genuine, long-term sustainability, ensuring that the environmental benefit is not negated by premature product replacement.

For further reading on the chemical processes involved in polymer degradation, a comprehensive review of the topic is available from the National Institute of Standards and Technology (NIST) here.

The technical data confirms that for applications requiring high dimensional stability and long-term performance in tropical climates, WSC is the technically superior material, offering a more reliable and truly sustainable solution.

For more details on the manufacturing process that utilizes these stable materials, please refer to our article on rPET injection molding.

Related Articles

The Technical Superiority of rPET Lanyards: A B2B Guide for Sustainable Procurement in Singapore

A deep technical analysis for Singapore B2B procurement professionals on rPET lanyards. We examine the material science, advanced weaving processes, and strategic alignment with the Singapore Green Plan 2030, proving rPET's technical superiority and sustainability over virgin polyester.

The Unrivalled Durability of UV Printing for Corporate Gifts in Singapore's Climate

For Singapore's B2B sector, selecting the right branding method for corporate gifts is critical. This deep-dive compares UV printing and screen printing, focusing on how UV technology offers superior durability, environmental compliance, and aesthetic quality, especially against the challenges of the tropical climate.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now