The Science of Superior Corporate Gifting: Why 304 Stainless Steel Vacuum Tumblers are a Strategic B2B Investment in Singapore

In Singapore’s competitive B2B landscape, corporate gifts are more than mere tokens of appreciation; they are tangible extensions of a brand’s values, commitment to quality, and dedication to sustainability. For procurement managers, HR directors, and marketing heads, the challenge lies in selecting a gift that offers both high perceived value and genuine, long-term utility. The stainless steel vacuum insulated tumbler has emerged as a perennial favourite, yet not all tumblers are created equal. The true value—and the reflection of your brand’s integrity—lies in the unseen science: the thermal physics of its insulation and the material composition of its steel.

This authoritative guide delves into the engineering and material science that separates a premium, enduring corporate gift from a short-lived commodity. We will explore the critical role of vacuum technology and the non-negotiable importance of using certified 304-grade stainless steel, particularly within the context of Singapore’s stringent quality expectations and its national sustainability agenda, the Singapore Green Plan 2030.

The Thermal Physics of Vacuum Insulation: Defeating Heat Transfer

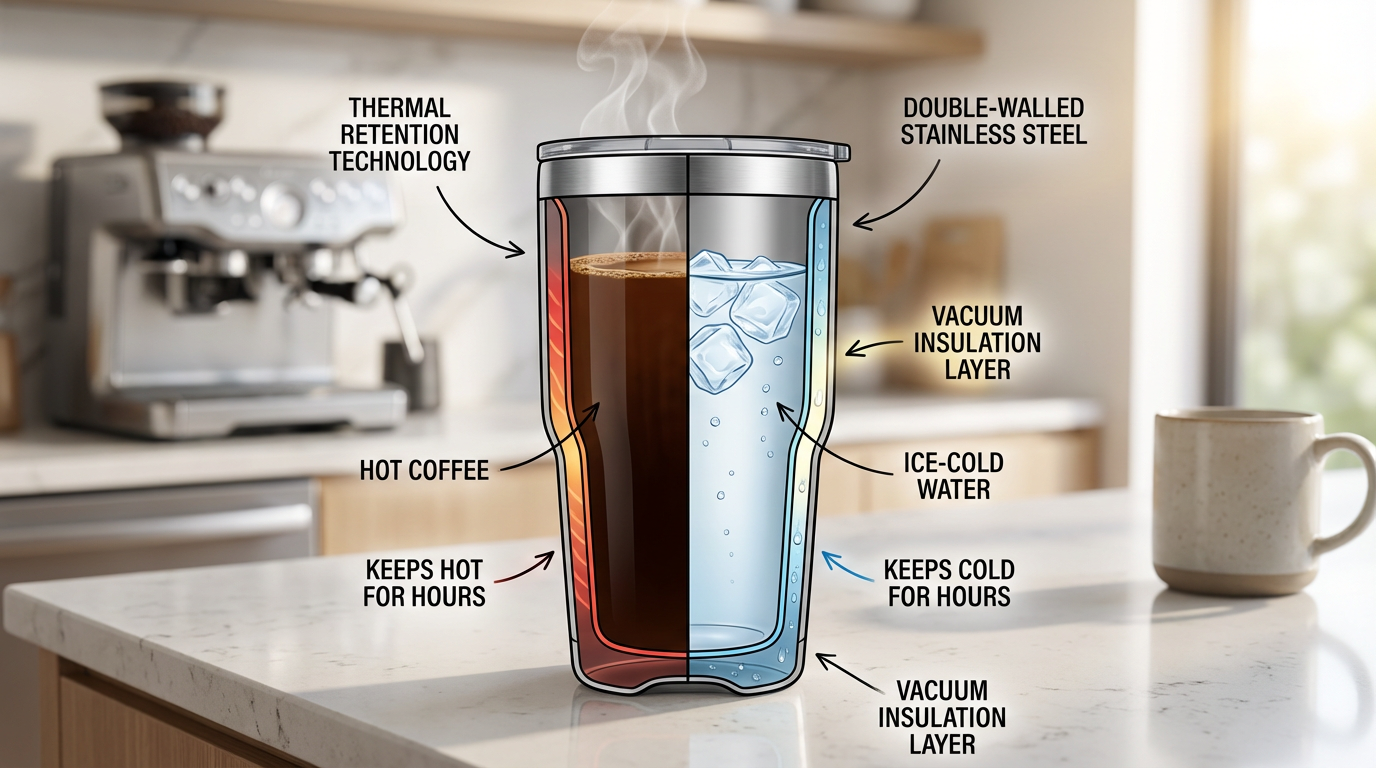

The ability of a high-quality tumbler to keep a beverage hot for 12 hours or cold for 24 hours is not magic; it is a precise application of thermal physics. Heat transfer occurs through three primary mechanisms: conduction, convection, and radiation. A well-engineered double-wall vacuum insulated (DWVI) tumbler is designed to minimise all three simultaneously.

Conduction: The Barrier of the Vacuum

Conduction is the transfer of heat through direct contact between materials. In a standard single-wall cup, heat from the liquid is rapidly conducted through the metal to the outer surface, which is then transferred to the environment or the holder’s hand. The DWVI design features two walls of stainless steel separated by a gap. Crucially, the air in this gap is evacuated, creating a near-perfect vacuum.

Since heat conduction requires a medium (like air or metal) for molecular vibration to pass energy, the vacuum acts as a powerful insulator. With virtually no air molecules present, there is no medium for heat to conduct across the gap, drastically slowing the rate of temperature change. This engineering choice is fundamental to the tumbler’s performance and is a key differentiator in quality manufacturing.

Convection: Eliminating Air Movement

Convection is the transfer of heat through the movement of fluids (liquids or gases). In a non-insulated vessel, the air surrounding the cup heats up, rises, and is replaced by cooler air, creating a continuous cycle of heat loss. By removing the air between the two walls, the vacuum layer eliminates the possibility of convection currents forming within the insulation space. This ensures that the heat energy remains trapped within the inner chamber, further preserving the beverage’s temperature.

Radiation: The Role of Copper Lining

Even in a vacuum, heat can still be transferred via thermal radiation, which is energy transmitted in the form of electromagnetic waves (infrared light). To combat this, premium tumblers often feature an additional layer—a thin coating of copper or silver applied to the exterior of the inner wall. Copper is a highly reflective material that acts as a radiant barrier, reflecting the heat waves back into the liquid (if hot) or back into the environment (if cold). This final, often overlooked, technical detail is what truly optimises the tumbler’s thermal performance, ensuring superior heat retention compared to models that rely solely on the vacuum.

Material Integrity: The Non-Negotiable Case for 304 Stainless Steel

The choice of stainless steel grade is arguably the most critical factor for a corporate gift, impacting not only durability but also user safety and brand reputation. The industry standard for high-quality, food-contact applications is Type 304 Stainless Steel, often referred to as 18/8 steel due to its composition of approximately 18% chromium and 8% nickel.

304 vs. 201: A Critical Distinction for B2B Gifting

While some manufacturers use the cheaper Type 201 Stainless Steel to reduce costs, this compromise carries significant risks that are unacceptable for a premium corporate gift. The difference lies primarily in the nickel and manganese content:

- 304 Steel (The Premium Choice): The high nickel content provides exceptional resistance to corrosion, rust, and pitting, even when exposed to acidic liquids like coffee, tea, or fruit juices. This longevity is crucial in Singapore’s high-humidity environment, where inferior metals can degrade quickly. It is certified food-grade and non-leaching, ensuring the safety and purity of the contents over years of use.

- 201 Steel (The Cost-Cutting Alternative): This grade substitutes a significant portion of the expensive nickel with cheaper manganese. While initially appearing similar, 201 steel is far more susceptible to corrosion and rust, particularly along weld lines or in the presence of chlorides (salt). Over time, this degradation can lead to the leaching of metals into the beverage, posing a health risk and severely damaging your brand’s reputation for quality and care.

For a discerning Singapore B2B audience, a gift that fails prematurely or raises health concerns is counterproductive. Choosing certified 304 stainless steel is a statement of quality assurance and ethical sourcing.

Comparison of Stainless Steel Grades

| Feature | Type 304 Stainless Steel (18/8) | Type 201 Stainless Steel |

|---|---|---|

| Composition (Key) | ~18% Chromium, ~8% Nickel | ~16% Chromium, ~3.5-5.5% Nickel, High Manganese |

| Corrosion Resistance | Excellent. Highly resistant to rust and pitting, ideal for acidic beverages and humid climates. | Fair to Poor. Susceptible to rust and corrosion, especially in high-chloride or acidic environments. |

| Food Safety | Certified Food-Grade. Non-leaching and safe for long-term food and beverage contact. | Conditional. Not recommended for long-term contact with acidic foods; higher risk of metal leaching. |

| Durability/Hardness | Excellent ductility and formability; less prone to cracking. | Harder and more brittle; can be more difficult to deep-draw and prone to stress corrosion cracking. |

| Cost | Higher (due to nickel content). | Lower (cost-cutting alternative). |

Manufacturing and Quality Control: Ensuring Lasting Performance

The final performance of a tumbler is determined by the precision of its manufacturing process. Creating a reliable vacuum requires meticulous engineering. The process involves:

- Forming: The inner and outer shells are precisely shaped.

- Welding: The two shells are joined at the rim with a seamless weld.

- Vacuum Sealing: A small hole (often at the base) is used to pump out the air, creating the vacuum. This hole is then sealed, often with a metal pellet or cap, which is a key indicator of a true vacuum-sealed product.

A failure at any of these stages—a poor weld, an incomplete vacuum, or a compromised seal—will render the insulation ineffective. This is why quality assurance is paramount. Reputable suppliers conduct rigorous heat retention testing, often adhering to international standards, to verify that the product maintains temperature within specified tolerances. When selecting a corporate gift, insist on transparency regarding these quality control measures and the material certifications.

Furthermore, the exterior finish and branding method must be equally durable. For guidance on selecting the best customisation technique for stainless steel, we recommend reviewing our detailed guide on custom branding eco-products.

Strategic Alignment: Tumblers and the Singapore Green Plan 2030

In Singapore, corporate responsibility is increasingly measured against national goals. The Singapore Green Plan 2030 sets ambitious targets for sustainable development, including a goal to reduce the amount of waste sent to Semakau Landfill by 30% by 2030. This national imperative directly influences corporate procurement decisions.

Reusable stainless steel tumblers are a direct, practical contribution to the 'Zero Waste' pillar of the Green Plan. By providing employees, clients, and partners with a high-quality, durable tumbler, companies actively promote the reduction of single-use plastic and paper cups—a tangible step towards compliance with the National Environment Agency (NEA)'s waste minimisation efforts. A premium 304 stainless steel tumbler, designed for longevity, signals a company’s commitment to genuine sustainability, moving beyond mere greenwashing.

The shift towards sustainable corporate gifting is not just a trend; it is a strategic necessity that enhances a company's Environmental, Social, and Governance (ESG) profile. For more insights into how to align your gifting strategy with future sustainability goals, explore our analysis of sustainable corporate gifts Singapore 2025 trends.

Conclusion: Investing in Quality, Investing in Brand Equity

The science behind the stainless steel vacuum insulated tumbler is clear: superior thermal performance is achieved through the meticulous combination of vacuum physics and high-grade materials. For Singapore’s B2B sector, choosing a corporate gift is a decision that reflects on the brand’s commitment to quality, safety, and sustainability.

By insisting on certified 304 (18/8) stainless steel, you ensure a product that offers exceptional corrosion resistance, non-leaching safety, and the durability required to withstand Singapore’s climate and years of daily use. This choice transforms a simple piece of drinkware into a powerful, long-lasting brand ambassador that aligns perfectly with the nation’s sustainability objectives.

Elevate your corporate gifting programme by choosing products engineered for excellence and designed for a sustainable future. Discover our full range of certified 304 stainless steel drinkware and other eco-friendly solutions in our comprehensive product catalogue.

Related Articles

The Branding Trap: How Your Logo Dictates Your MOQ

Did you know that a full-color logo can triple your Minimum Order Quantity? A procurement consultant explains how different decoration methods—from laser engraving to heat transfer—impose their own hidden MOQs on top of the product's base requirement.

The Real Timeline of Custom Manufacturing: A Procurement Guide for Singapore Enterprises

Stop guessing your event timeline. A 15-year supply chain expert reveals the hidden bottlenecks in custom manufacturing—from mold stabilization to multi-SKU risks.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now