"I'm ordering 1,000 units total—why does it matter if I split them into 5 colors?"

This is the most common question I hear from procurement teams trying to meet a Minimum Order Quantity (MOQ). On paper, the math works: 200 Red + 200 Blue + 200 Green + 200 Yellow + 200 Black = 1,000 units. You have met the volume requirement.

But on the factory floor, you haven't placed one order for 1,000 units. You have placed **five separate orders for 200 units each**.

To a production manager, "Total Volume" is a financial concept, but "SKU Variance" is an operational reality. Understanding why we penalize "mixing and matching" requires looking at what actually happens on the assembly line when we switch from Red to Blue.

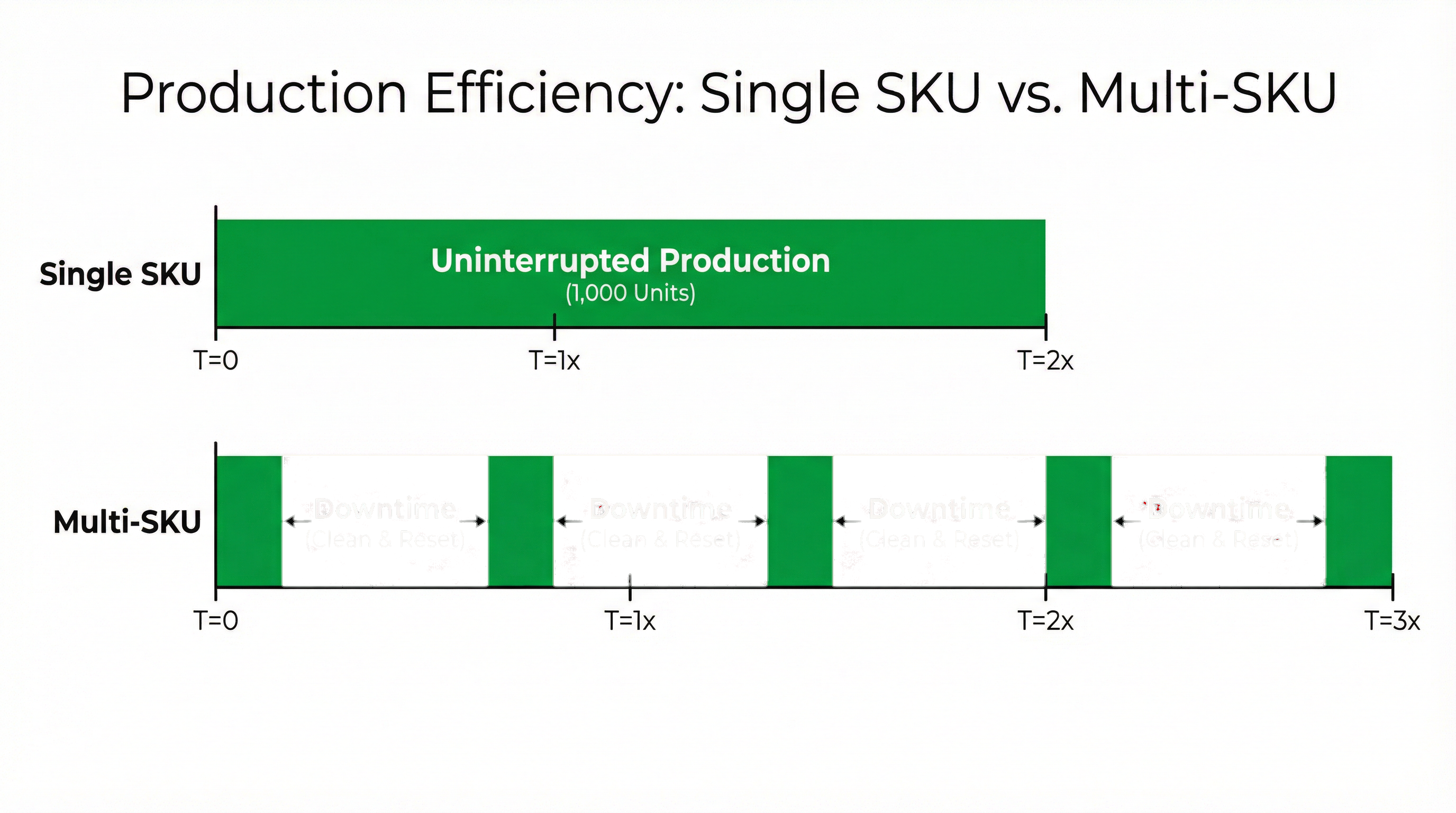

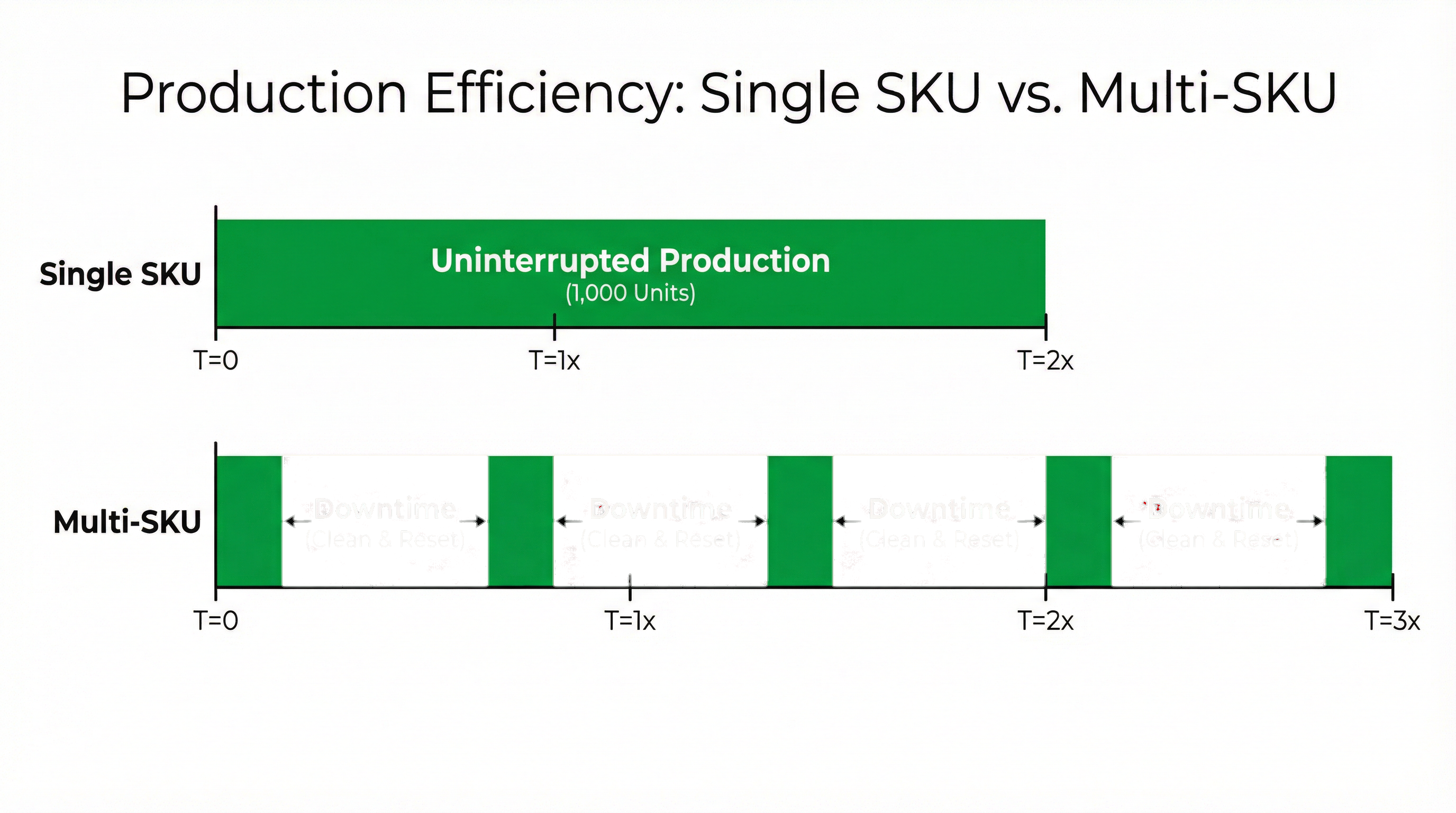

### The "Stop-Start" Penalty

Modern manufacturing relies on **Continuous Flow**. An assembly line is like a highway; it is most efficient when cars (products) are moving at a constant high speed. Every time we change a Stock Keeping Unit (SKU)—whether it's a color, a size, or a logo print—we have to stop the traffic.

**1. The Purge and Clean (30-60 Minutes)**

If we are injection molding your lunch boxes, switching from Black to Yellow isn't just a button press. We have to purge the machine of black resin, clean the hopper, and run test shots until the yellow comes out pure. That is an hour of downtime where the machine is running but producing nothing but waste.

**2. The Packaging Reset (15-30 Minutes)**

Even if the product is identical and only the packaging changes (e.g., a different barcode sticker), the packing line must halt. Workers have to clear away the "Red SKU" boxes, bring in the "Blue SKU" boxes, and recalibrate the labeling machines.

**3. The "Ramp-Up" Risk**

Every time a line restarts, the error rate spikes. The first 50 units after a changeover are where mistakes happen—a label applied crookedly, a streak of old color, or a wrong barcode. By splitting your 1,000 units into five small batches, you are forcing us to go through this high-risk "ramp-up" phase five times instead of once.

### The "Ghost Inventory" Problem

SKU variance also creates a nightmare in the warehouse.

If you order 1,000 units of a single SKU, we can palletize them efficiently. We know exactly how many cartons fit on a pallet.

If you order 200 units of 5 SKUs, we end up with "partial pallets." We might have 1.5 pallets of Red, 0.8 pallets of Blue, and so on. These odd lots take up more floor space and require more manual handling to pick and pack.

Furthermore, if we overproduce the Red units by 10% (a common buffer), we are stuck with 20 extra Red units that we can't ship because you only ordered 200. In a single 1,000-unit run, that overage is easily absorbed. In small batches, it becomes "dead stock" that clutters our shelves.

### How to Optimize Your SKU Mix

If you absolutely need variety, you don't have to abandon the idea. You just need to align your variety with the factory's "Changeover Economics."

**1. Consolidate "Hard" Changes**

Try to keep the "hard" variables constant. For example, order 1,000 units in **one color** (e.g., Natural Bamboo), but differentiate them with **five different laser-engraved logos** or **five different paper sleeves**. Changing a laser file or a paper sleeve takes minutes; changing a plastic resin color takes hours.

**2. The "80/20" Rule**

Instead of an even split (200 x 5), commit to a dominant SKU. Order 800 units in your primary brand color (meeting the efficiency threshold) and 200 units in a secondary color. We are often more willing to accommodate one small "side run" if the main run keeps the lights on.

**3. Accept "Master Carton" Multiples**

If our master carton holds 50 units, don't order 225. Order 200 or 250. Asking for broken cartons forces manual counting and repacking, which slows down the line and invites counting errors.

In practice, this is often where SKU variance decisions start to be misjudged. You see "variety" as a customer benefit; we see it as "friction." By reducing that friction—grouping your variances into the final assembly steps rather than the raw material steps—you can often get the variety you need without triggering the "Per SKU" surcharges that kill your budget.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now