One of the most frustrating moments in corporate procurement occurs right at the finish line. You have successfully negotiated a 200-unit order for premium bamboo tumblers, confirmed the laser engraving, and approved the pre-production sample. Then, you ask for a custom-printed gift box to complete the presentation.

The supplier’s answer is immediate and jarring: "For custom boxes, the minimum is 1,000 units."

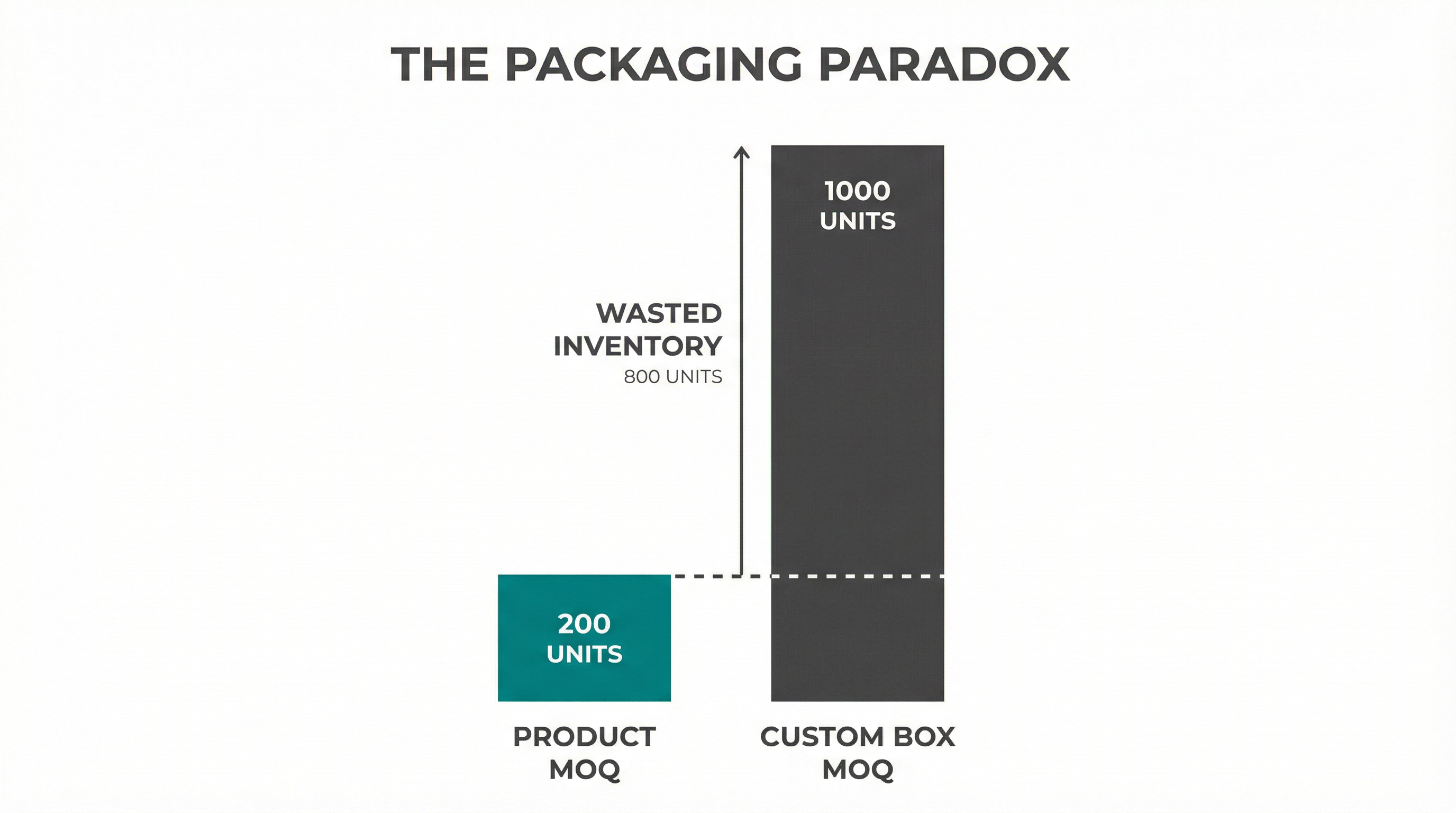

This scenario, often called the "Packaging Paradox," is a structural mismatch in the supply chain that catches even experienced buyers off guard. While product manufacturing has evolved to support lower volumes through CNC machining and digital customization, the packaging industry—specifically the sector responsible for high-quality rigid boxes—remains tethered to high-volume industrial processes.

Understanding why this gap exists is the first step to managing it without blowing your budget or your warehouse space.

### The Offset Printing Threshold

The primary culprit behind high packaging MOQs is the printing technology itself. High-end retail packaging typically relies on **offset lithography**, a process that delivers the crispest text, the most accurate Pantone color matching, and the smoothest gradients.

However, offset printing has a massive "setup penalty." It requires burning physical aluminum plates for each color (Cyan, Magenta, Yellow, Black, plus any spot colors), mixing custom inks, and calibrating a press the size of a bus. The first 100 to 200 sheets run through the press are often scrap—used solely to align the registration and get the colors up to density.

If you order 200 boxes, you are essentially paying for 400 sheets of material and hours of skilled labor just to get the machine running. The unit cost becomes astronomical. This is why packaging factories set hard floors—often at 500 or 1,000 units—to ensure the job is profitable.

### The "Rigid Box" Labor Factor

Beyond printing, the construction of the box itself drives MOQs. A standard "folding carton" (like a toothpaste box) is die-cut and glued by machine at high speeds. But a "rigid box" (like an iPhone box)—the kind most corporate gifts demand—is different.

Rigid boxes are often **semi-handmade**. A worker must manually wrap the printed paper around the greyboard core, ensuring no bubbles or wrinkles appear at the corners. This manual assembly line requires a team of people to be pulled off other jobs. Factories cannot justify disrupting a line of 20 workers to assemble 200 boxes; the opportunity cost of stopping a larger run is simply too high.

### Strategic Solutions for Low-Volume Gifting

When you face a 200-unit product order against a 1,000-unit packaging MOQ, you have three financially viable paths.

**1. The "Over-Order and Store" Strategy**

If you know you will reorder the same gift (or a similar-sized one) within 12 months, ordering the 1,000 boxes is often the smartest financial move. You pay for the packaging bulk run upfront, use 200 now, and ask the supplier to warehouse the remaining 800 flat-packed. The per-unit cost of a 1,000-run box is often 60-70% cheaper than a 500-run box, meaning the total spend might be surprisingly similar, but you secure inventory for future campaigns.

**2. The "Generic Box + Custom Sleeve" Hybrid**

A highly effective compromise is to use a high-quality *unbranded* stock box (in black, white, or kraft) and wrap it with a custom-printed paper sleeve or "belly band." Sleeves can be digitally printed in low volumes (even 50 units) without the high setup costs of offset printing. This gives you a fully branded unboxing experience while bypassing the rigid box manufacturing constraints.

**3. Digital Printing (With Caveats)**

Digital printing for packaging has improved, allowing for "plate-free" production of corrugated mailer boxes. While the print quality is slightly grainier than offset and Pantone matching is less precise, it allows for true MOQ-1 production. For e-commerce style mailers, this is a viable option, though it lacks the "luxury" feel of a wrapped rigid box.

In practice, this is often where packaging decisions start to be misjudged. Buyers assume the box is just an accessory, but in the eyes of the factory, it is a separate manufacturing project with its own rigid economic laws. By decoupling the product quantity from the packaging quantity, you can navigate this mismatch and find a solution that protects both your brand image and your bottom line.

Packaging MOQ

Custom Box Minimums

Offset Printing Costs

Rigid Box Manufacturing

Procurement Strategy

Related Articles

The Opportunity Cost of Stopping the Line: Why Factories Reject Small Orders

Why would a factory refuse your order even if you offer to pay a higher unit price? A production manager explains the hidden economics of 'Machine Downtime' and why stopping a high-speed line for a small run is a financial loss.

Read More

The Real Timeline of Custom Manufacturing: A Procurement Guide for Singapore Enterprises

Stop guessing your event timeline. A 15-year supply chain expert reveals the hidden bottlenecks in custom manufacturing—from mold stabilization to multi-SKU risks.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now