In the world of corporate gifting, the desire for uniqueness is natural. You don't just want a standard bamboo fiber lunch box; you want one with a custom-molded compartment for a sauce container, or a handle shaped like your company logo. It seems like a simple design tweak.

Then the quote arrives. The unit price is reasonable, but there is a line item at the bottom: **"Mold Fee: $5,500"**—or alternatively, a requirement to order **10,000 units** to waive that fee.

This is the "Shape Premium." Unlike color changes (which involve mixing pigments) or logo printing (which involves making a small plate), changing the physical geometry of a product requires cutting a new **Injection Mold**.

Understanding the economics of this steel block is the key to deciding whether your custom shape is a brilliant branding investment or a financial sinkhole.

### The "Private Mold" vs. "Open Mold" Reality

To a factory, every product starts as a block of high-grade steel. CNC machines carve this steel into a negative cavity of your product—a process that takes weeks and costs thousands of dollars.

**1. Open Molds (Public Molds)**

These are molds the factory has already paid for. They own the design, and anyone can order products from them. The amortization cost is spread over millions of units sold to hundreds of clients. This is why you can buy 100 standard lunch boxes at a low price; the tool is already "paid off."

**2. Private Molds (Custom Tooling)**

When you demand a unique shape, you are asking for a "Private Mold." You own the intellectual property, and the factory cannot sell this shape to anyone else. Consequently, **you alone must pay for the steel.**

The factory has two ways to charge you for this:

* **Upfront Tooling Fee:** You pay $5,000 cash for the mold. The unit price remains low (e.g., $3.00/unit) because it only covers material and labor.

* **Amortized MOQ:** The factory waives the upfront fee but inflates the unit price (e.g., to $3.50/unit) and demands a massive MOQ (e.g., 10,000 units). They are essentially lending you the mold cost and collecting it back 50 cents at a time.

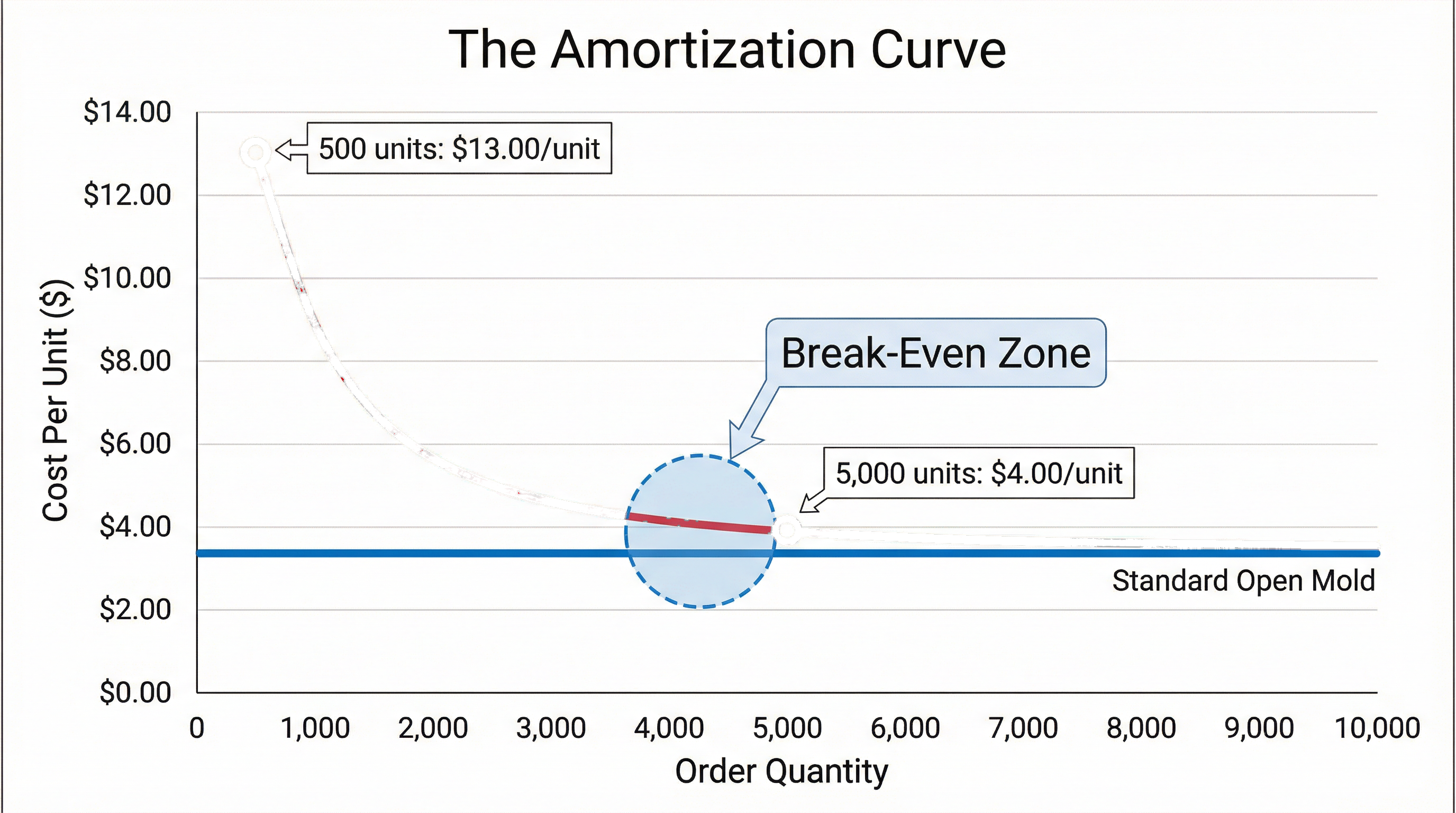

### The Amortization Break-Even Point

This leads to a critical calculation: **Is it cheaper to pay the fee or buy the volume?**

Imagine you need 2,000 custom-shaped bento boxes.

* **Option A (Pay Tooling):** $5,000 Mold Fee + ($3.00 x 2,000 units) = **$11,000 Total** ($5.50/unit average).

* **Option B (High MOQ):** Factory demands 10,000 units at $3.50. Total = **$35,000**.

In this scenario, paying the upfront tooling fee is drastically cheaper, even though it "feels" like a large expense. However, if you only need 500 units, the average cost becomes ($5,000 + $1,500) / 500 = **$13.00 per box**. At that price, a standard "Open Mold" box with a high-end UV print (total cost ~$4.00) is a far superior value.

### Strategic Alternatives to Custom Molding

If your volume is under 5,000 units, cutting a private mold is rarely economically viable unless the product is the core of your business. For corporate gifts, we recommend three "Hybrid Customization" strategies:

**1. Custom Inserts, Standard Shell**

Use an existing "Open Mold" box or container, but create a custom **silicone or EVA foam insert**. Molds for silicone are significantly cheaper (often $500-$800) than steel injection molds. You get a custom internal layout without paying for the external shell tooling.

**2. The "Lid-Only" Customization**

Some factories use modular molds where the "cavity" (the box body) is fixed, but the "core" (the lid) can be swapped. You might be able to pay a smaller tooling fee just to emboss your logo into the lid plastic, rather than casting an entirely new container.

**3. CNC Machining (For Wood/Bamboo)**

If you choose solid bamboo or wood products instead of plastic, you escape the mold trap entirely. Wood is cut by CNC routers, not cast in molds. Changing the shape just means changing a software file. While the *per-unit* cost of wood is higher, the *setup* cost is near zero, making it ideal for runs of 100-500 custom-shaped units.

In practice, this is often where design ambition meets procurement reality. A custom shape is the ultimate brand flex, but it carries a heavy "steel tax." By calculating the amortization per unit, you can determine if that unique curve is worth the premium, or if a standard shape with brilliant surface design can achieve the same effect for a fraction of the capital.

Injection Mold Cost

Tooling Amortization

Private Mold vs Open Mold

Custom Shape MOQ

Procurement Strategy

Related Articles

The Opportunity Cost of Stopping the Line: Why Factories Reject Small Orders

Why would a factory refuse your order even if you offer to pay a higher unit price? A production manager explains the hidden economics of 'Machine Downtime' and why stopping a high-speed line for a small run is a financial loss.

Read More

The Real Timeline of Custom Manufacturing: A Procurement Guide for Singapore Enterprises

Stop guessing your event timeline. A 15-year supply chain expert reveals the hidden bottlenecks in custom manufacturing—from mold stabilization to multi-SKU risks.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now