As a production manager who has overseen thousands of injection molding runs, I often see the same look of confusion on a buyer's face. You want 500 reusable coffee cups. We have them in stock in black, white, and navy blue. But when you ask for them in your specific brand color—Pantone 326 C (Teal)—I have to tell you the minimum order quantity (MOQ) just jumped to 3,000 units.

It feels arbitrary. Why does changing a color code triple the required volume?

The answer lies in the physics of plastic manufacturing, specifically a granular substance called **Masterbatch**. Understanding how we actually color plastic will help you see why "just one specific shade" is never a small request in a factory setting.

### The 4% Rule: How Plastic Gets Its Color

Most people assume we buy "teal plastic" pellets and melt them down. We don't. We buy raw, clear, or natural polypropylene (PP) or ABS resin by the ton. To color it, we mix in a concentrated pigment called Masterbatch.

The standard mixing ratio—or "Let Down Ratio" (LDR)—is typically between 2% and 4%. This means for every 100kg of plastic, we add 2kg to 4kg of this super-concentrated color pigment.

Here is the constraint: **Masterbatch suppliers have their own MOQs.**

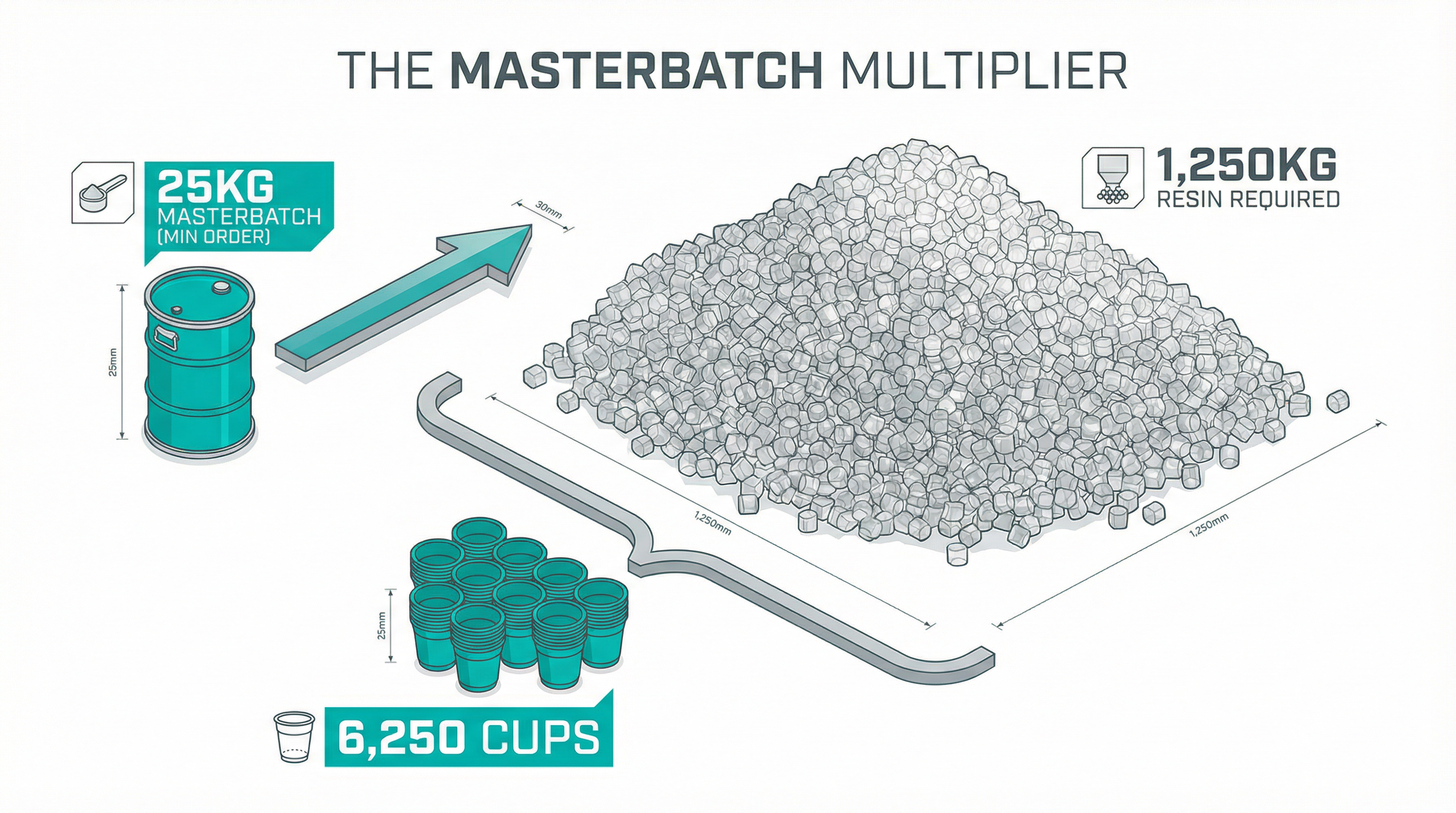

To create a custom Pantone masterbatch, a pigment lab must formulate a unique recipe, extrude it, cool it, and chop it into pellets. Their minimum run is usually 25kg. If we are forced to buy 25kg of your custom teal masterbatch, and we mix it at a 2% ratio, that 25kg of pigment is enough to color **1,250kg of plastic**.

If your coffee cup weighs 200 grams, 1,250kg of material produces **6,250 cups**.

Even if we negotiate the masterbatch supplier down to a smaller 10kg sample run (which costs a premium), that still colors 500kg of resin—enough for 2,500 cups. This is the mathematical floor. We cannot buy "just enough" pigment for 500 cups because the pigment factory cannot turn on their machines for less than a standard batch.

### The "Purge" Penalty

There is a second hidden cost that drives up your MOQ: the machine changeover.

An injection molding machine is essentially a giant heated screw pushing molten plastic. When we switch from black to your custom teal, we cannot just swap the hopper. The black residue remains inside the barrel and the screw threads.

To clean it, we have to "purge" the machine—running natural, uncolored plastic through it until it comes out clear. Then we introduce your custom teal. The first few hundred shots will be streaky or contaminated with black specks.

This process wastes 50kg to 100kg of raw material and takes 2-3 hours of machine downtime. If you order 5,000 cups, this waste is a negligible fraction of the cost. If you order 500 cups, the cost of the wasted material and the lost machine time might exceed the profit margin of the entire order.

### How to Navigate the Color Constraint

If you are a procurement officer facing this "Color Tax," you have three practical options to avoid the 3,000-unit cliff.

**1. The "Stock Color" Compromise**

Ask your supplier for their "Stock Color Card." Most factories keep 10-15 standard colors (Red 485C, Blue 286C, etc.) on hand. If your brand guidelines allow for "Royal Blue" instead of your exact "Electric Cobalt," you can often stick to the lower standard MOQ (e.g., 500 units).

**2. Pay the "Surcharge" (If Available)**

Some factories will allow you to order 500 units in a custom color if you pay for the *entire* minimum batch of masterbatch. You are essentially paying for the 25kg of pigment but only using 2kg of it. This might add $300-$500 to your total bill, but it saves you from buying 2,500 extra cups you don't need.

**3. Post-Production Painting**

For some products (like stainless steel bottles), we don't color the material; we spray paint it. Spray painting has lower setup thresholds than injection molding masterbatch. You might be able to get a custom Pantone spray on 500 units, though the unit cost will be higher due to the manual labor involved.

In practice, this is often where branding decisions collide with manufacturing reality. Your marketing team demands exact Pantone matching, but the masterbatch ratio dictates the volume. By understanding that color is a volume game, you can decide whether that specific shade of teal is worth the inventory risk, or if a standard color with a custom-printed logo will achieve the same brand impact.

Masterbatch

Pantone Matching

Injection Molding MOQ

Plastic Coloring

Procurement Strategy

Related Articles

The Opportunity Cost of Stopping the Line: Why Factories Reject Small Orders

Why would a factory refuse your order even if you offer to pay a higher unit price? A production manager explains the hidden economics of 'Machine Downtime' and why stopping a high-speed line for a small run is a financial loss.

Read More

The Pantone Illusion: Why Bio-Materials Defy Standard Color Matching

Why your wheat straw product doesn't match your Pantone chip. A factory project manager explains the physics of substrate interference in eco-friendly manufacturing.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now