Every Q4, I see the same panic. A Marketing Director orders 5,000 custom umbrellas to get the best 'bulk price', only to realize their office pantry cannot store 50 cartons of merchandise. They end up renting expensive third-party storage or cluttering the boardroom. This is where the Split Shipment strategy becomes a game-changer. It allows companies to lock in the volume discount of a large production run while staggering the delivery to match their consumption or event schedule.

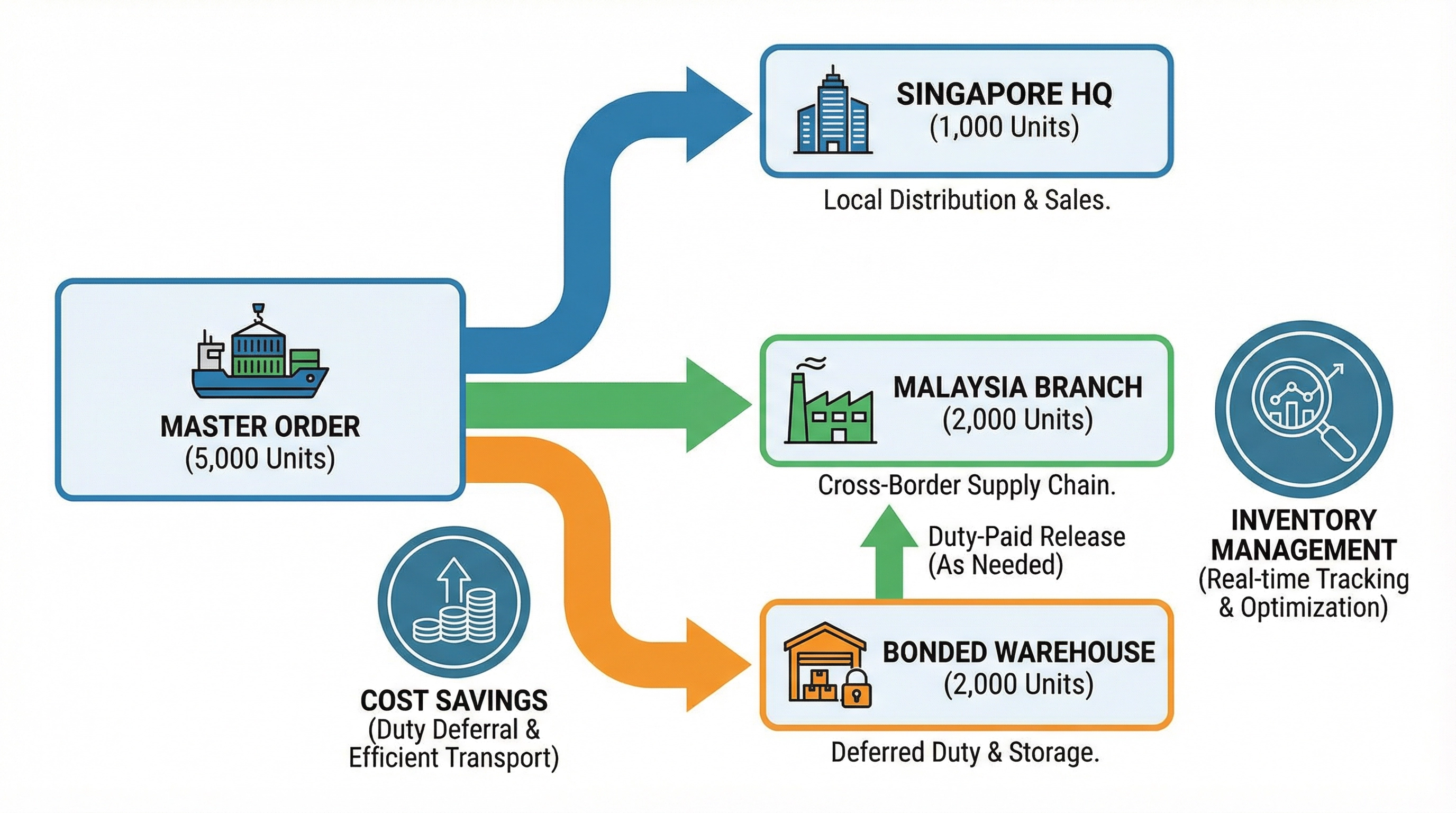

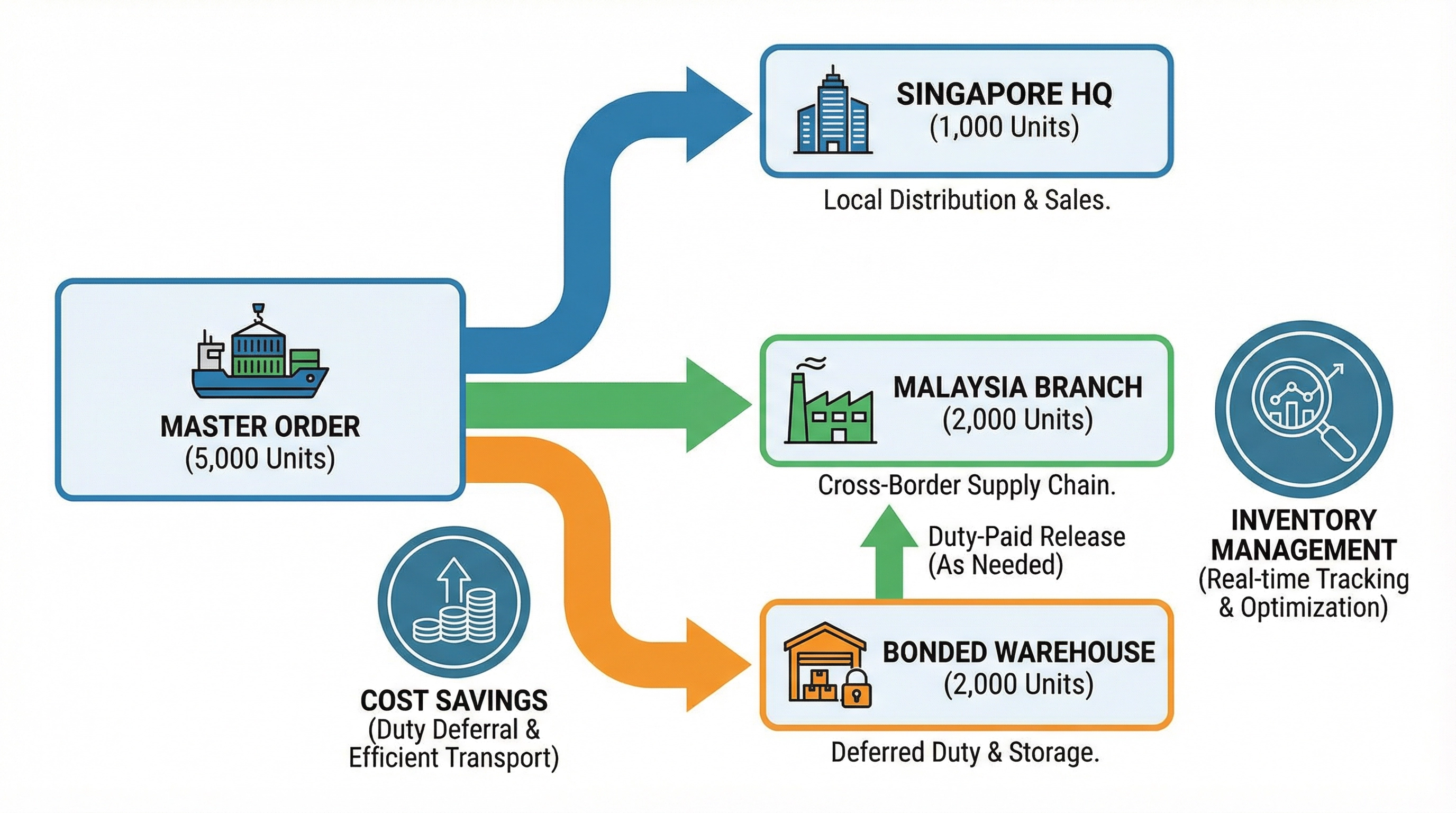

For example, a regional bank might order 10,000 welcome packs. Instead of shipping everything to their Raffles Place HQ (where rent is $12 psf), we ship 2,000 units immediately for the Singapore launch. The remaining 8,000 are held at our factory warehouse in China or a bonded warehouse in Singapore, to be dispatched in batches of 1,000 to their branches in Kuala Lumpur, Jakarta, and Bangkok over the next six months. This 'Just-in-Time' model drastically reduces local storage costs and handling labor.

The Hidden Risk: Storage Conditions

However, split shipments require strict quality control on the storage end. I once saw a batch of leather notebooks ruined by humidity because they were stored in a non-climate-controlled warehouse in Shenzhen for six months during the monsoon season. Mold grew on the covers. When negotiating a split shipment contract, always specify the storage conditions (temperature, humidity) and ask for a 'Pre-Shipment Inspection' for each subsequent batch. Do not assume the goods will stay pristine sitting in a box for a year.

Cash Flow Benefits: Beyond space, this strategy helps cash flow. We often structure payment terms so that the client pays for the production upfront (30-50%), but the balance and shipping costs are billed only when each batch is released. This turns a massive CAPEX hit into manageable OPEX monthly expenses, which keeps the Finance Department happy.

Question: Does split shipment cost more?

The shipping cost per unit might be slightly higher because you are sending smaller batches (LCL) instead of a full container (FCL). However, when you factor in the savings from not renting warehouse space in Singapore and the reduced risk of inventory obsolescence, the Total Cost of Ownership (TCO) is usually lower. We can calculate a comparison for you based on your specific volume.

Related Articles

The Technical Superiority of rPET Lanyards: A B2B Guide for Sustainable Procurement in Singapore

A deep technical analysis for Singapore B2B procurement professionals on rPET lanyards. We examine the material science, advanced weaving processes, and strategic alignment with the Singapore Green Plan 2030, proving rPET's technical superiority and sustainability over virgin polyester.

The Unrivalled Durability of UV Printing for Corporate Gifts in Singapore's Climate

For Singapore's B2B sector, selecting the right branding method for corporate gifts is critical. This deep-dive compares UV printing and screen printing, focusing on how UV technology offers superior durability, environmental compliance, and aesthetic quality, especially against the challenges of the tropical climate.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now