"Can we just order 50 pieces to start?" This is the most common question I hear from SMEs and startups. It seems like a prudent, low-risk request. However, as a Procurement Strategist, I have to explain the counter-intuitive reality of manufacturing economics: buying less often costs disproportionately more. The concept of Minimum Order Quantity (MOQ) is not an arbitrary hurdle set by suppliers to be difficult; it is a mathematical necessity derived from the ratio of Fixed Costs to Variable Costs.

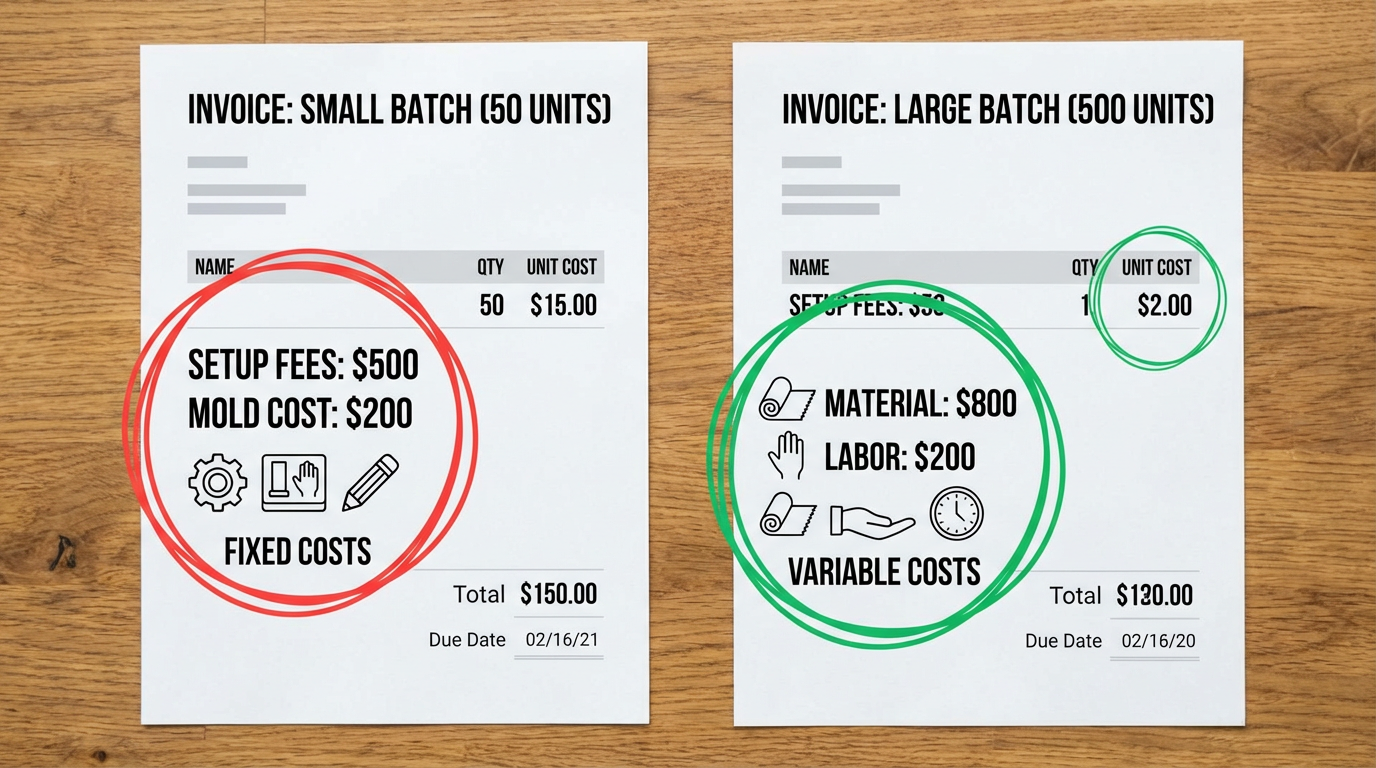

Every customized production run, whether it's 50 pens or 5,000, incurs a set of Fixed Costs. These include:

- Machine Setup: Calibrating the laser engraver, mixing the specific ink color, or setting up the silk screen frame. This takes the same amount of time regardless of the run length.

- Pre-production Proofing: The design team's time to convert logos, create digital mockups, and verify print files.

- Tooling/Molds: For custom shapes, the cost of the metal mold is significant and upfront.

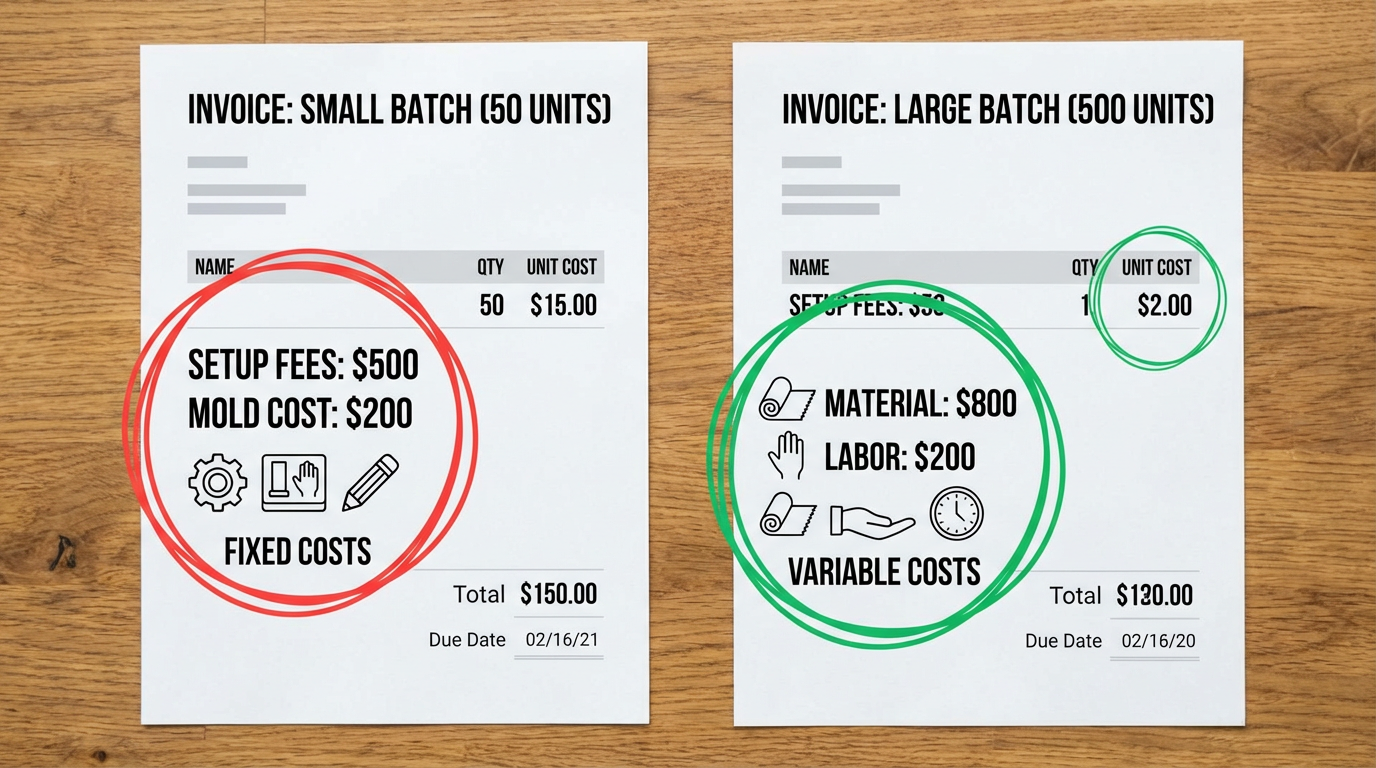

Let's look at a real-world scenario. Suppose the fixed setup cost for a logo print is $100. If you order 50 items, that setup adds $2.00 to every single item. If you order 500 items, that same $100 setup cost is spread out, adding only $0.20 per item. That's a 90% reduction in the setup portion of the unit cost. When you add in the Variable Costs (materials, labor, shipping), the total unit price for the small batch skyrockets.

The 'Hidden' Logistics of Small Batches

Beyond production, logistics plays a huge role. Shipping 50 items often falls below the minimum weight for freight consolidation, forcing us to use courier services (like DHL or FedEx) which have much higher rates per kilogram. Furthermore, the administrative cost of processing an order—invoicing, packing lists, customs declarations—is identical for small and large orders. Suppliers often add a 'Small Order Surcharge' to cover this administrative overhead.

Supply Chain Reality Check: I once managed a project for a tech startup that insisted on 50 custom-dyed tote bags. The dyeing vat required a minimum of 100kg of fabric to operate effectively. To fulfill the order, the factory had to dye the minimum batch and discard the excess fabric, or charge the client for the full 100kg. The client ended up paying a unit price that was 400% higher than the standard rate. The lesson? Flexibility in MOQ often comes at a premium that erodes the ROI of the gifting campaign.

For companies with smaller needs, the smart strategy is not to fight the MOQ, but to consolidate demand. Can you combine the HR department's onboarding gifts with the Sales team's client giveaways? Can you order for the whole year and ask the supplier to hold stock (warehousing)? Understanding the math behind the MOQ empowers you to make smarter, more efficient procurement decisions.

Question: Why is the unit price so high for a small order?

High unit prices on small orders are primarily due to fixed setup costs (like machine calibration, mold fees, and design work) being amortized over fewer units. For example, a $100 setup fee adds $2.00 per unit to a 50-piece order, but only $0.10 per unit to a 1,000-piece order. Logistics and administrative costs also do not scale down linearly, keeping the per-unit cost high.

Related Articles

The Opportunity Cost of Stopping the Line: Why Factories Reject Small Orders

Why would a factory refuse your order even if you offer to pay a higher unit price? A production manager explains the hidden economics of 'Machine Downtime' and why stopping a high-speed line for a small run is a financial loss.

The Pantone Illusion: Why Bio-Materials Defy Standard Color Matching

Why your wheat straw product doesn't match your Pantone chip. A factory project manager explains the physics of substrate interference in eco-friendly manufacturing.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now