Recycled stainless steel is a fantastic material for corporate drinkware—durable, premium, and sustainable. However, it presents a unique challenge for branding: surface energy. As a Surface Finishing Engineer, I often encounter clients who are baffled when their beautiful, full-color UV printed logos start peeling off their premium bottles after just a few washes. The culprit is rarely the ink itself, but the invisible battle between the ink's surface tension and the substrate's surface energy.

Stainless steel, particularly recycled grades which may have varying surface chemistries due to the recycling process, often has a low surface energy (measured in Dyne/cm). UV ink, being a liquid photopolymer, needs a high-energy surface to 'wet out' and bond effectively. If the bottle's surface energy is lower than the ink's surface tension, the ink will bead up rather than spread, leading to poor mechanical adhesion. When the ink cures under UV light, it forms a film sitting *on top* of the metal rather than bonding *to* it.

The Pre-Treatment Protocol: Flame and Primer

To solve this, we employ a rigorous pre-treatment protocol. The first step is often Flame Treatment. By passing the stainless steel product briefly through a gas flame, we oxidize the surface, creating polar groups that significantly increase the surface energy (raising the Dyne level). This allows the UV ink to flow into the microscopic peaks and valleys of the metal surface.

For maximum durability, especially for drinkware that will undergo repeated dishwashing, we use a specialized adhesion promoter (primer). This chemical agent acts as a bridge. One end of the primer molecule bonds chemically with the metal oxide layer of the stainless steel, while the other end contains functional groups that react with the UV ink during the curing process. This creates a chemical bond that is far stronger than a simple mechanical grip.

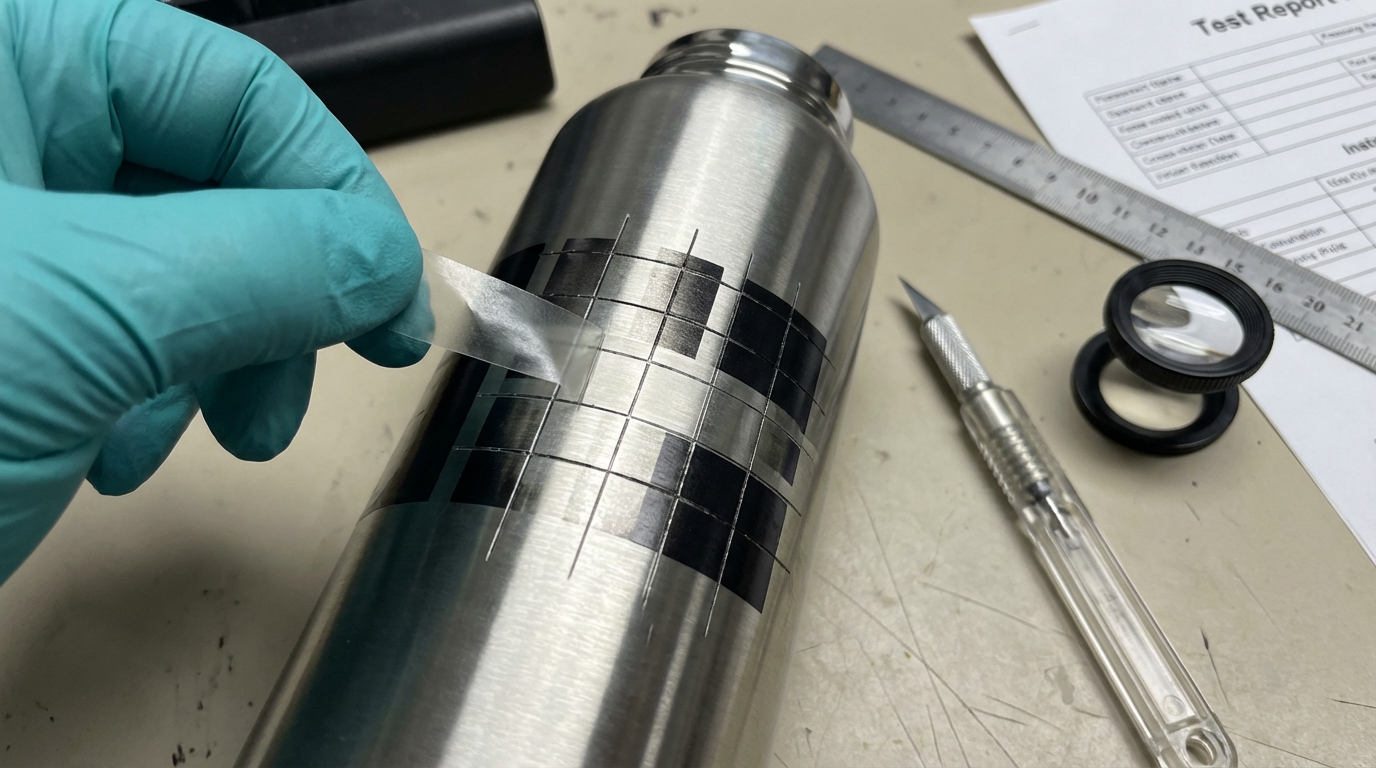

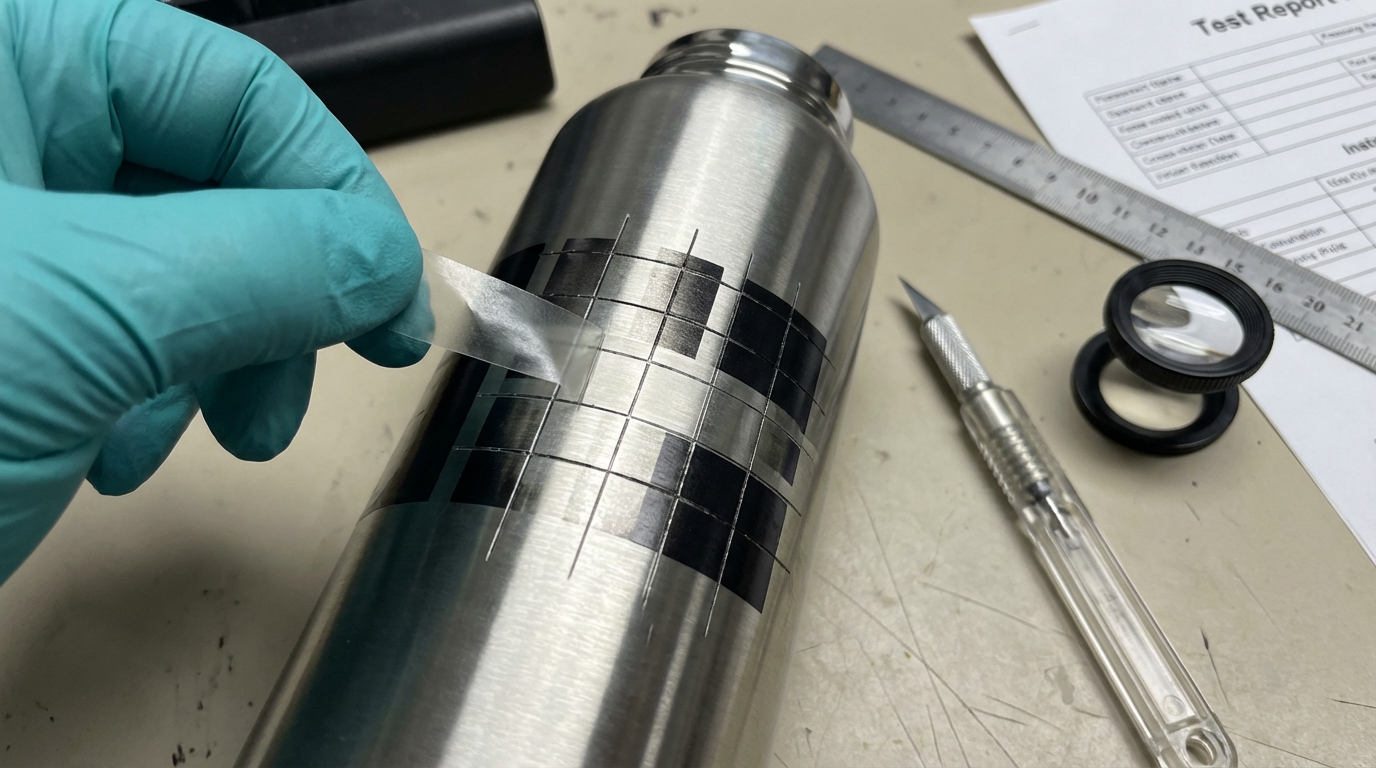

Verification: The Cross-Cut Test

We don't guess; we test. The industry standard for verifying adhesion is the ASTM D3359 Cross-Cut Tape Test. We use a specialized cutter to make a lattice pattern of cuts through the printed logo down to the metal substrate. Pressure-sensitive tape is applied over the cut area and then rapidly peeled off. The adhesion is rated on a scale from 0B (more than 65% area removed) to 5B (0% area removed). At EcoSential Works, any batch that scores below 4B is rejected.

This attention to surface science is what differentiates a premium corporate gift from a cheap giveaway. A logo that withstands the test of time (and the office dishwasher) reflects the enduring quality of the brand it represents. It ensures that the investment in sustainable merchandise continues to pay dividends in brand visibility long after the initial gifting.

Question: Why does the printed logo on my metal bottle peel off?

Peeling usually occurs because the stainless steel surface was not properly pre-treated to increase its surface energy, preventing the UV ink from bonding effectively. High-quality printing requires flame treatment or a chemical primer to ensure the ink adheres chemically to the metal, followed by proper UV curing.

Related Articles

UV Printing Adhesion: Glass vs. Stainless Steel in Corporate Gifting

A technical breakdown of surface tension, primer application, and UV curing energy requirements for printing on non-porous substrates.

Laser Engraving vs. UV Printing: A Microscopic Analysis of Logo Longevity on Recycled Stainless Steel

An R&D specialist's deep dive into the microscopic adhesion and physical abrasion resistance of laser-engraved and UV-printed logos on recycled stainless steel corporate gifts.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now