In the realm of sustainable corporate tableware, the distinction between genuine bamboo fiber composites and melamine-blended imitations is often blurred by marketing terminology. As a material engineer specializing in polymer composites, I frequently encounter procurement teams who believe they are purchasing '100% natural' bamboo products, only to discover they have acquired a melamine matrix with bamboo filler. This distinction is not merely semantic; it fundamentally alters the thermal stability, migration limits, and end-of-life biodegradability of the product.

### The Structural Matrix: Where the Difference Lies

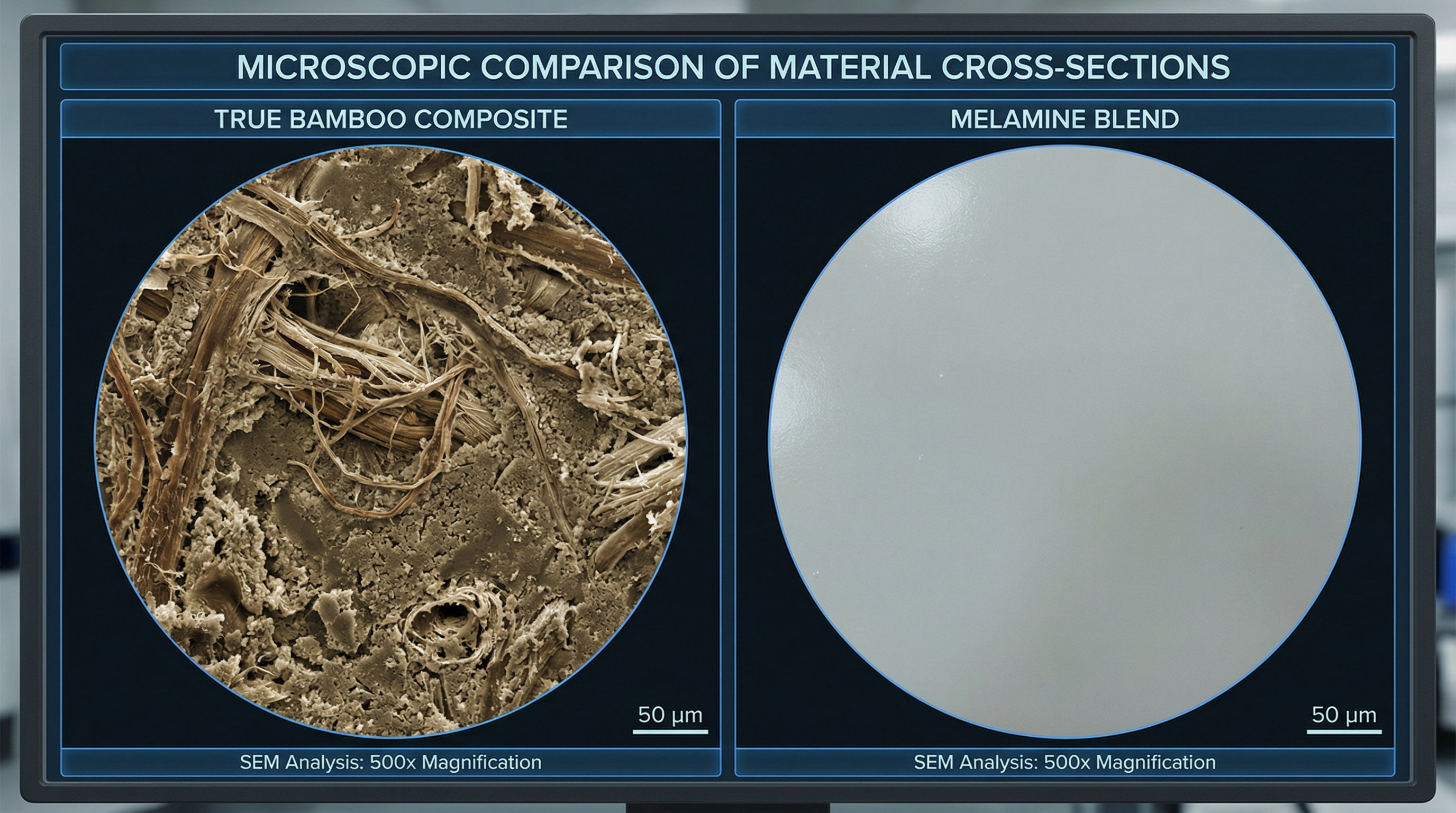

True bamboo fiber composites utilize a plant-based binder (often PLA or starch-based) to hold the bamboo powder together. Under a scanning electron microscope (SEM), this structure appears relatively porous and organic. In contrast, melamine-bamboo blends use a formaldehyde-melamine resin as the binder. While this imparts higher surface gloss and hardness, it also introduces the risk of formaldehyde migration if the curing process is not strictly controlled. For corporate pantries and high-frequency usage environments, understanding this matrix is critical for employee safety compliance.

### Common Misconception: 'Unbreakable' Equals Better

One of the most pervasive errors in corporate procurement is the assumption that 'unbreakable' implies superior quality for sustainable goods. Melamine-bamboo blends are indeed more shatter-resistant than PLA-bamboo composites, but this physical resilience comes at a chemical cost. High-impact resistance in these blends is often achieved by increasing the ratio of melamine resin, effectively diluting the eco-friendly component to less than 30%. A truly sustainable bamboo composite will have a more matte finish and a distinct tactile warmth, whereas the imitation will feel cold and sound high-pitched like standard plastic when tapped.

### Mass Production Variables: The Heat Curing Trap

When moving from prototype to mass production, the most significant failure point for bamboo composites is the heat curing cycle. In my experience auditing factories in Fujian and Zhejiang, I have seen manufacturers rush the compression molding cycle to increase output. Reducing the dwell time by even 15 seconds can result in incomplete polymerization. For the end user, this manifests as 'blistering' or surface bubbling after a few cycles in a commercial dishwasher. This is not a material defect but a process violation. We strictly enforce a minimum 120-second dwell time at 160°C for all our bamboo composite lines to ensure full cross-linking.

### Engineer's Note on Procurement

"Is it safe to put these bamboo cups in the office microwave?"

Engineer's Response: Absolutely not for melamine-blended bamboo. The microwave excites the water molecules in the bamboo filler, creating internal steam pressure that can micro-crack the rigid melamine matrix, leading to rapid chemical migration. Only specific PLA-based bamboo composites are rated for short-duration microwave use, and even then, we recommend avoiding it to prolong product life.

For further reading on material safety standards, refer to our analysis on [PLA heat resistance](/news/technical-1-pla-heat-resistance) or explore the logistics of [customs clearance for organic materials](/news/b2b-4-customs-clearance-delays).

bamboo fiber safety

melamine migration

corporate tableware materials

sustainable composite analysis

Related Articles

The 70/30 Myth: Decoding Resin Ratios in Bamboo Fiber Composites

A polymer chemist exposes the reality of bamboo fiber composites. We analyze the resin binders used, the truth about biodegradability, and why the '70% bamboo' claim can be misleading for sustainable procurement.

Read More

The Opportunity Cost of Stopping the Line: Why Factories Reject Small Orders

Why would a factory refuse your order even if you offer to pay a higher unit price? A production manager explains the hidden economics of 'Machine Downtime' and why stopping a high-speed line for a small run is a financial loss.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now