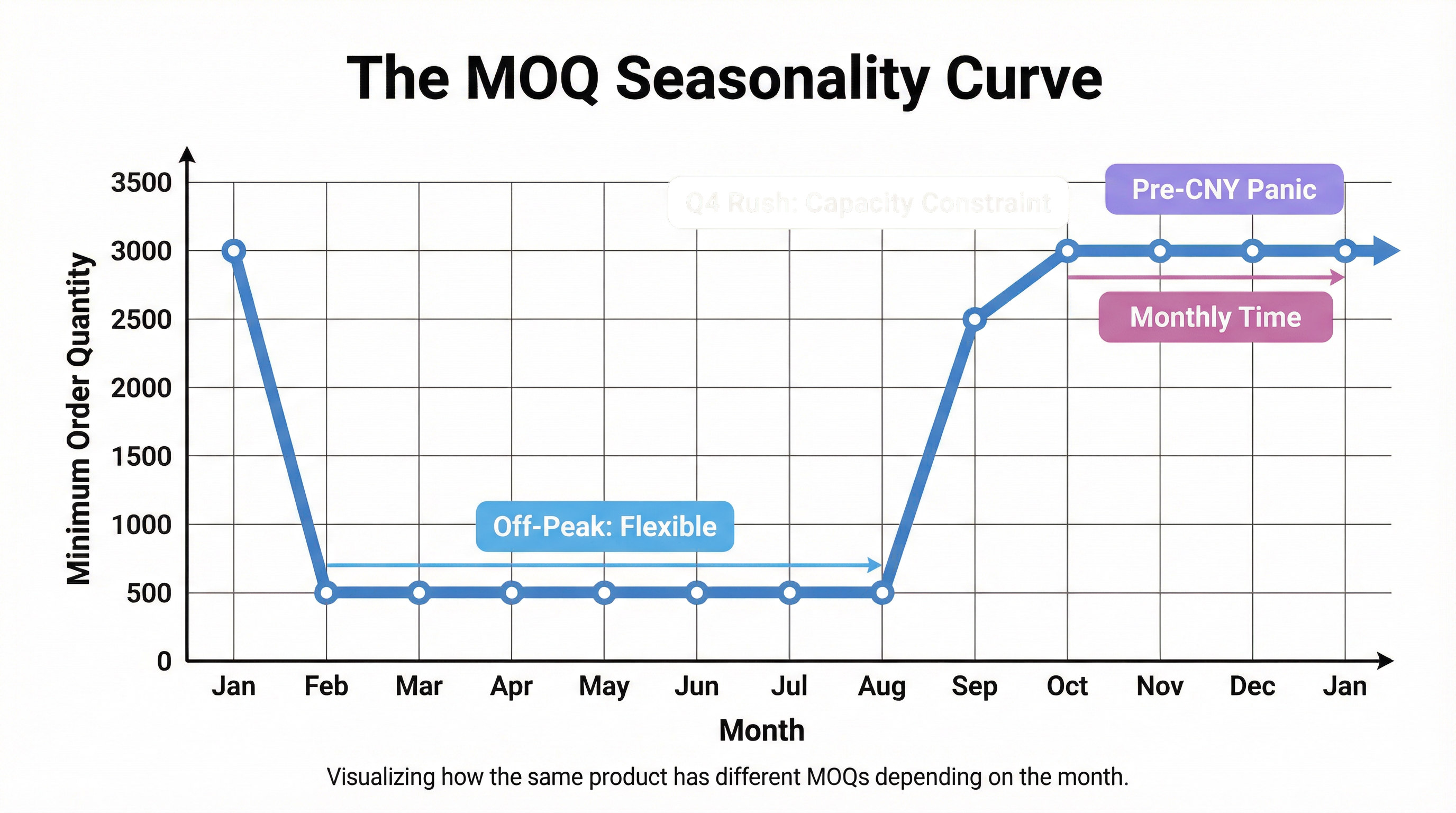

It is a scenario I see every year. A client places a 500-unit order for custom bamboo cutlery in April, and we produce it happily. They come back in October with the exact same order—same specs, same price—and I have to turn them down. Or, I have to tell them the new Minimum Order Quantity (MOQ) is 3,000 units.

They feel cheated. "You did it for me last time!" they argue.

But manufacturing is not a static service like cloud storage. It is a finite resource, bound by time and labor. The reason your small order is rejected in Q4 isn't because we became greedy; it's because you walked off the **Calendar Cliff**.

### The "Golden Capacity" of Q4

From January to August, factories operate in a "Fill the Line" mode. We have idle machines and workers on payroll who need to be kept busy. During these months, a 500-unit order is a lifeline. It keeps the lights on and the team sharp. We are willing to absorb the inefficiency of a small setup just to keep the factory humming.

Then comes September.

Suddenly, the "Q4 Rush" begins. Retailers are stocking up for Christmas. Corporate clients are ordering thousands of year-end gifts. Our order book fills up instantly.

In October, every hour of machine time is "Golden Capacity." We are overbooked. We have to choose between running a 50,000-unit order for a major retailer or your 500-unit restock. The setup time for both is the same (e.g., 2 hours).

* **Scenario A:** 2 hours setup + 50 hours running big order = 96% efficiency.

* **Scenario B:** 2 hours setup + 1 hour running your small order = 33% efficiency.

In Q4, we literally cannot afford the downtime of Scenario B. To justify stopping the big order to squeeze you in, your order needs to be big enough to offset the disruption. That is why the MOQ jumps from 500 to 3,000. We are not raising the price; we are raising the *threshold for entry*.

### The "Pre-CNY" Panic

The situation gets even more critical as we approach Chinese New Year (CNY), usually in late January or early February.

Most people know factories close for 2-3 weeks. What they don't know is the **"Pre-Departure Exodus."** Workers start leaving for their hometowns 2 weeks *before* the holiday to beat the travel rush. By mid-January, our workforce is down to 70%.

At the same time, every client in the world is trying to get their goods shipped *before* the shutdown. This creates a "Perfect Storm" of shrinking capacity and spiking demand.

In this environment, small orders are the first casualty. We simply do not have the manpower to handle the administrative and logistical overhead of 50 small shipments. We focus entirely on clearing the massive containers that keep our biggest clients happy.

### How to Beat the Calendar

If you are a procurement officer, you cannot change the factory's schedule. But you can change yours.

**1. The "April-August" Window**

Place your small, experimental, or high-complexity orders between April and August. This is when we are hungry. You will get lower MOQs, better attention to detail, and faster lead times. Use this time to pilot new designs.

**2. The "September Stockpile"**

Do not wait until November to order your year-end gifts. Forecast your Q4 needs in August and place the order in September. Even if you don't need the goods until December, secure the production slot early.

**3. The "Blanket Order" Strategy**

If you know you will need 2,000 units over the year but only have cash for 500 now, negotiate a "Blanket Order." Commit to the 2,000 units upfront, pay a deposit for the raw materials, and ask us to produce them all in the "off-season." We can hold the stock and ship it to you in quarterly batches. This locks in the lower "off-season" pricing and guarantees supply during the Q4 crunch.

In practice, this is often where seasonality decisions start to be misjudged. You treat procurement as an "on-demand" activity, while we treat production as a "capacity allocation" game. By aligning your buying cycle with our manufacturing rhythm, you can avoid the Calendar Cliff and get the service of a VIP client, even with a smaller budget.

Q4 Manufacturing Rush

Chinese New Year Delays

Factory Capacity Allocation

Seasonal MOQ

Procurement Timing

Related Articles

The Opportunity Cost of Stopping the Line: Why Factories Reject Small Orders

Why would a factory refuse your order even if you offer to pay a higher unit price? A production manager explains the hidden economics of 'Machine Downtime' and why stopping a high-speed line for a small run is a financial loss.

Read More

The 2025 Imperative: Sustainable Corporate Gifting Trends Aligned with Singapore's Green Plan

An in-depth analysis of the sustainable corporate gifting trends for Singapore's B2B sector in 2025, focusing on alignment with the Singapore Green Plan 2030 and navigating local regulatory compliance.

Read More

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now