In supply chain management, we often talk about "economies of scale," but rarely do we visualize it as starkly as we do in ocean freight. When a procurement manager asks why the unit price for 500 custom tumblers is so much higher than for 2,000, they often suspect the factory is padding the margin. In reality, the culprit is often the "Logistics Floor"—the fixed costs of moving goods from a factory in China to a warehouse in Singapore.

As a logistics director, I see this daily: the physical act of shipping a small volume of goods is disproportionately expensive. This is because the global freight infrastructure is built for containers, not cartons. When you ship less than a full container, you enter the world of LCL (Less Than Container Load), where you pay for space you don't use and handling fees that don't scale down.

The "1 CBM" Minimum Rule

The most fundamental constraint in LCL shipping is the "1 CBM" (Cubic Meter) minimum. Freight forwarders and consolidators charge based on volume, but they almost universally set a billing minimum of 1 cubic meter.

To put this in perspective, 500 standard ceramic mugs might only occupy 0.5 CBM. However, you will be billed for the full 1 CBM. Effectively, you are paying to ship 0.5 CBM of "air." This immediately doubles your freight cost per unit compared to an order that actually fills that cubic meter.

In practice, this is often where Logistics & Freight Efficiency decisions start to be misjudged. A buyer calculates the "per mug" shipping cost based on a theoretical rate, ignoring the minimum billing threshold. When the invoice arrives, the effective freight rate is double what they projected, eating directly into the project's budget.

The Fixed Cost of Port Documentation

Beyond the ocean freight itself, there is a battery of fixed costs associated with every shipment, regardless of its size. In Singapore, importing a shipment involves a Bill of Lading (B/L) fee, PSA port handling charges, customs permit fees, and trucking minimums.

A typical "documentation and handling" bill for an LCL shipment might total SGD $350 to $500. This fee is virtually identical whether you are importing one pallet or five.

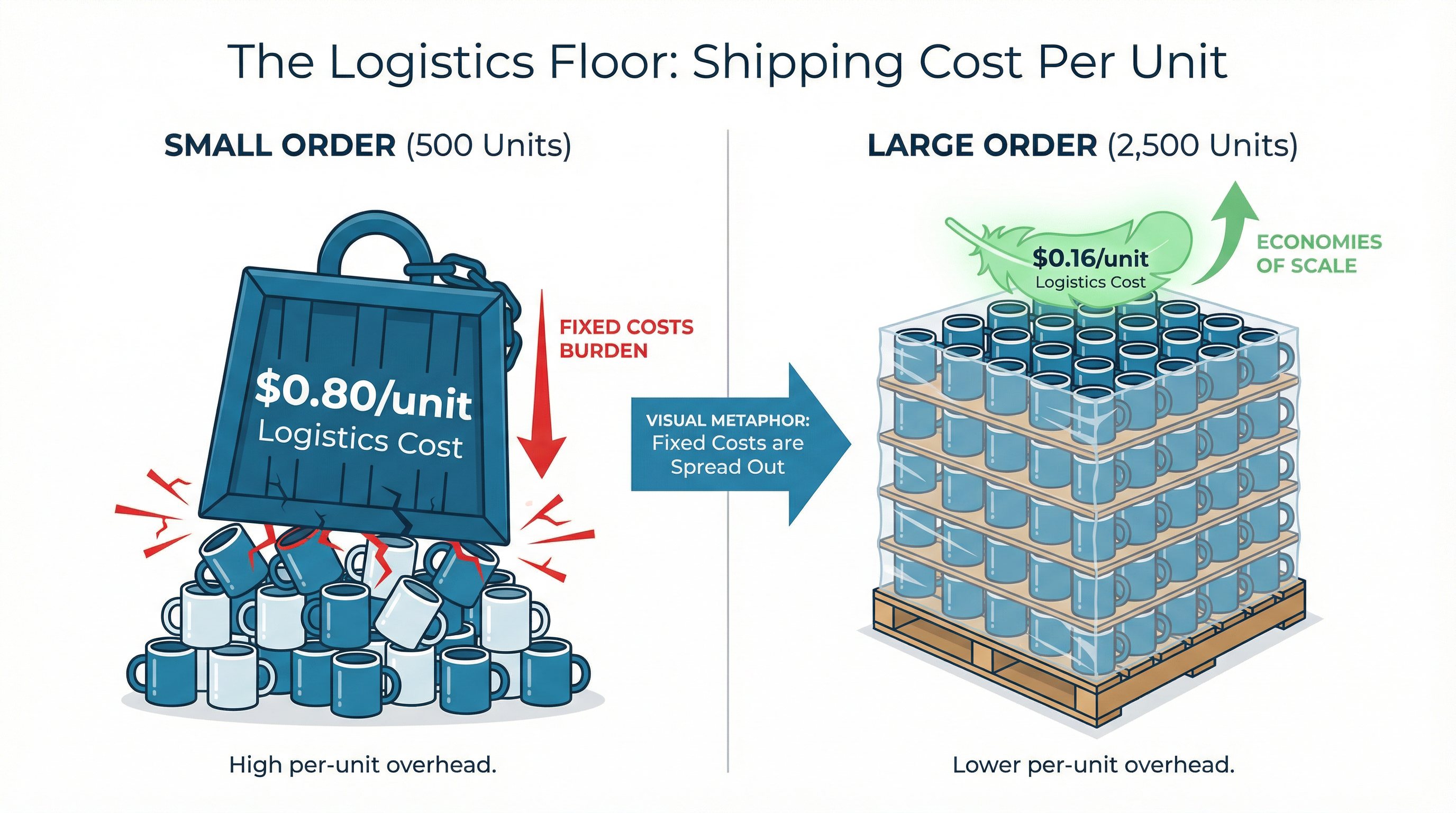

Let's do the math on the "Landed Cost Impact":

Scenario A (500 units): $400 fixed fees / 500 units = $0.80 per unit added to the cost.

Scenario B (2,500 units): $400 fixed fees / 2,500 units = $0.16 per unit added to the cost.

On a low-cost item like a wheat straw pen or a bamboo cutlery set, an extra $0.80 is a massive percentage increase. It can easily make the difference between a competitive quote and one that blows the budget. This is why we often advise clients that the "sweet spot" for logistics efficiency usually starts around 2-3 CBM, where the fixed costs are diluted enough to become negligible.

The "Last Mile" Trap

The inefficiency continues once the goods hit Singapore soil. A 14-foot lorry has a minimum trip charge. Delivering 10 cartons costs roughly the same as delivering 100 cartons because the driver's time, fuel, and vehicle depreciation are largely fixed per trip.

When you order below the optimal logistics volume, you are essentially paying for a dedicated truck to carry a fraction of its capacity. This "Last Mile" inefficiency is the final layer of the Logistics Floor, further penalizing small orders.

For a comprehensive breakdown of how these logistics costs integrate with manufacturing constraints, refer to our guide on What Is the Minimum Order Quantity (MOQ) for Customized Corporate Gifts?.

Ultimately, logistics is a volume game. The infrastructure of global trade punishes minimalism. Understanding the "Logistics Floor" helps procurement teams realize that increasing the order quantity is often the most effective way to lower the total unit cost, simply by stopping the payment for shipping air.

Related Articles

The Opportunity Cost of Stopping the Line: Why Factories Reject Small Orders

Why would a factory refuse your order even if you offer to pay a higher unit price? A production manager explains the hidden economics of 'Machine Downtime' and why stopping a high-speed line for a small run is a financial loss.

Logistics of WFH Care Packages: Ensuring Eco-Friendly Delivery

Sending care packages to remote teams? Learn how to optimize last-mile delivery and packaging to minimize the carbon footprint of your employee engagement initiatives.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now