In the world of corporate procurement, "safety" is often treated as a checkbox—a standard requirement that is assumed to be included in the unit price. However, when dealing with food contact materials (FCM) like bamboo fiber, wheat straw, or recycled plastics, safety is not a static attribute; it is a rigorous, expensive, and recurring process. As a compliance consultant helping brands navigate international regulations, I often see deals collapse not because of manufacturing costs, but because of the "Compliance Floor."

The Compliance Floor is the fixed cost of mandatory safety testing that must be paid regardless of whether you produce 500 units or 50,000 units. For eco-friendly tableware entering the Singapore market, this floor is significantly higher than most procurement teams realize, often making low-volume custom orders economically irrational.

The "Per-Batch" Reality of Lab Testing

A common misconception is that a factory's existing "FDA Certificate" covers every product they make forever. In reality, regulations like the US FDA 21 CFR, the German LFGB, and Singapore's SFA Food Regulations require testing on the specific formulation of the final product. If you change the color, the dye, or the ratio of bamboo powder to melamine binder, you have created a "new" material in the eyes of the law.

This triggers a requirement for a new set of migration tests. A standard LFGB migration test—which checks for the transfer of heavy metals, formaldehyde, and primary aromatic amines into food—can cost upwards of USD $1,500 to $2,000 per SKU. This is a fixed cost. The lab does not care if the sample comes from a production run of 100 or 100,000; the chemical analysis takes the same amount of time and reagents.

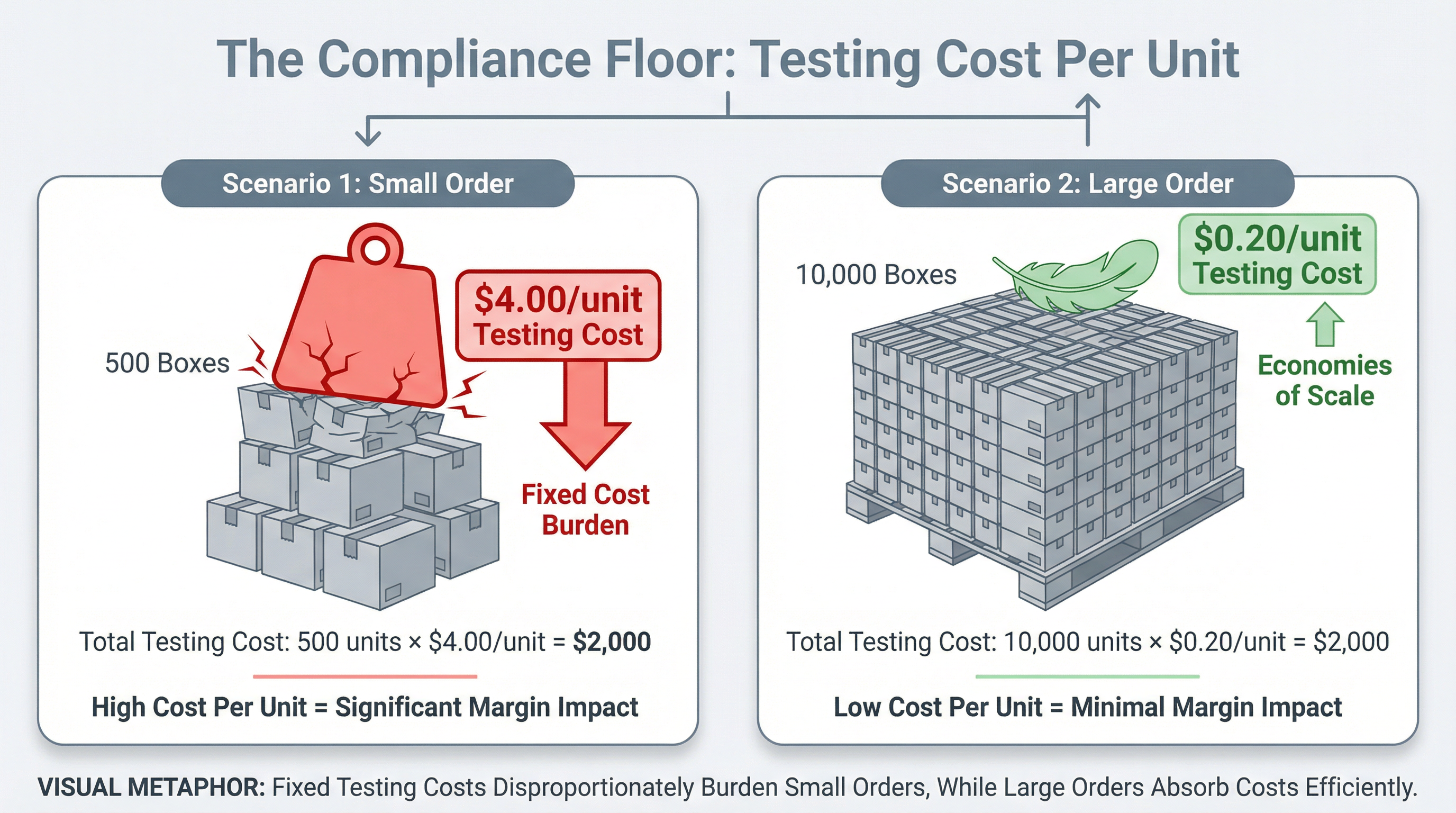

In practice, this is often where Batch-Level Compliance Testing Costs decisions start to be misjudged. A buyer might negotiate a unit price of $3.00 for a custom lunch box. But if they only order 500 units, the $2,000 testing fee adds a staggering $4.00 to every single unit—more than doubling the cost. Conversely, on an order of 10,000 units, that same fee adds just $0.20, a negligible margin impact.

The Risk of "Skipping" the Test

Faced with these costs, some buyers ask, "Can't we just use the factory's old report?" This is the most dangerous question in procurement. An outdated or generic test report is legally worthless if a safety incident occurs. In Singapore, the SFA has strict limits on the migration of substances like melamine and formaldehyde. If a batch of corporate gifts is found to be leaching chemicals into hot coffee, the liability falls on the importer—the company whose logo is on the cup.

For "natural" composites like bamboo fiber, the risk is even higher. These materials are often bound with melamine resin. If the curing process is not perfect (which can happen in small, rushed batches), the risk of chemical migration increases. A fresh, batch-specific test is the only insurance against this liability. Legitimate suppliers will refuse to produce a custom batch without this testing, effectively setting a hard MOQ based on the point where the testing cost becomes absorbable.

The "Compliance-Adjusted" MOQ

When we calculate MOQ for food contact products, we are essentially solving an equation: At what quantity does the amortized cost of compliance fall below 5% of the unit price?

For a standard FDA test (cheaper, around $800), the "Compliance Floor" might be 1,000 units. For the stricter LFGB test (expensive, around $2,000+), the floor might rise to 3,000 units. Below these thresholds, you are paying more for the proof of safety than for the product itself.

This economic reality forces a binary choice for low-volume buyers:

1. Stick to "Market Standard" Specs: Buy products that the factory is already producing for major global clients. In this scenario, the testing cost has already been amortized across hundreds of thousands of units. You get the safety assurance without the direct bill.

2. Pay the "Safety Surcharge": If you absolutely must have a custom "Pantone 286C" silicone seal on a lunch box for a 300-person event, be prepared to pay a separate line item for lab testing. This is not price gouging; it is the literal cost of ensuring your colleagues don't ingest toxic chemicals.

For a broader view of how these regulatory costs fit into the total cost of ownership, refer to our guide on What Is the Minimum Order Quantity (MOQ) for Customized Corporate Gifts?.

Ultimately, compliance is not a variable cost; it is a fixed barrier to entry. Understanding this helps procurement teams realize that a high MOQ on food-safe products is often a sign of a responsible supplier, not a difficult one.

Related Articles

The Compliance Barrier: Why a $800 Lab Test Kills Your 500-Unit Order

Why 'Food Contact Safety' isn't just a checkbox—it's a fixed cost that makes small orders financially impossible.

The Opportunity Cost of Stopping the Line: Why Factories Reject Small Orders

Why would a factory refuse your order even if you offer to pay a higher unit price? A production manager explains the hidden economics of 'Machine Downtime' and why stopping a high-speed line for a small run is a financial loss.

Need Professional Corporate Gifting Advice?

From material selection to logo printing and logistics, our team is here to provide expert guidance for your needs.

Contact Us Now